2

1. INTRODUCTION

1.1. Features

1.2.

2.

2.1.

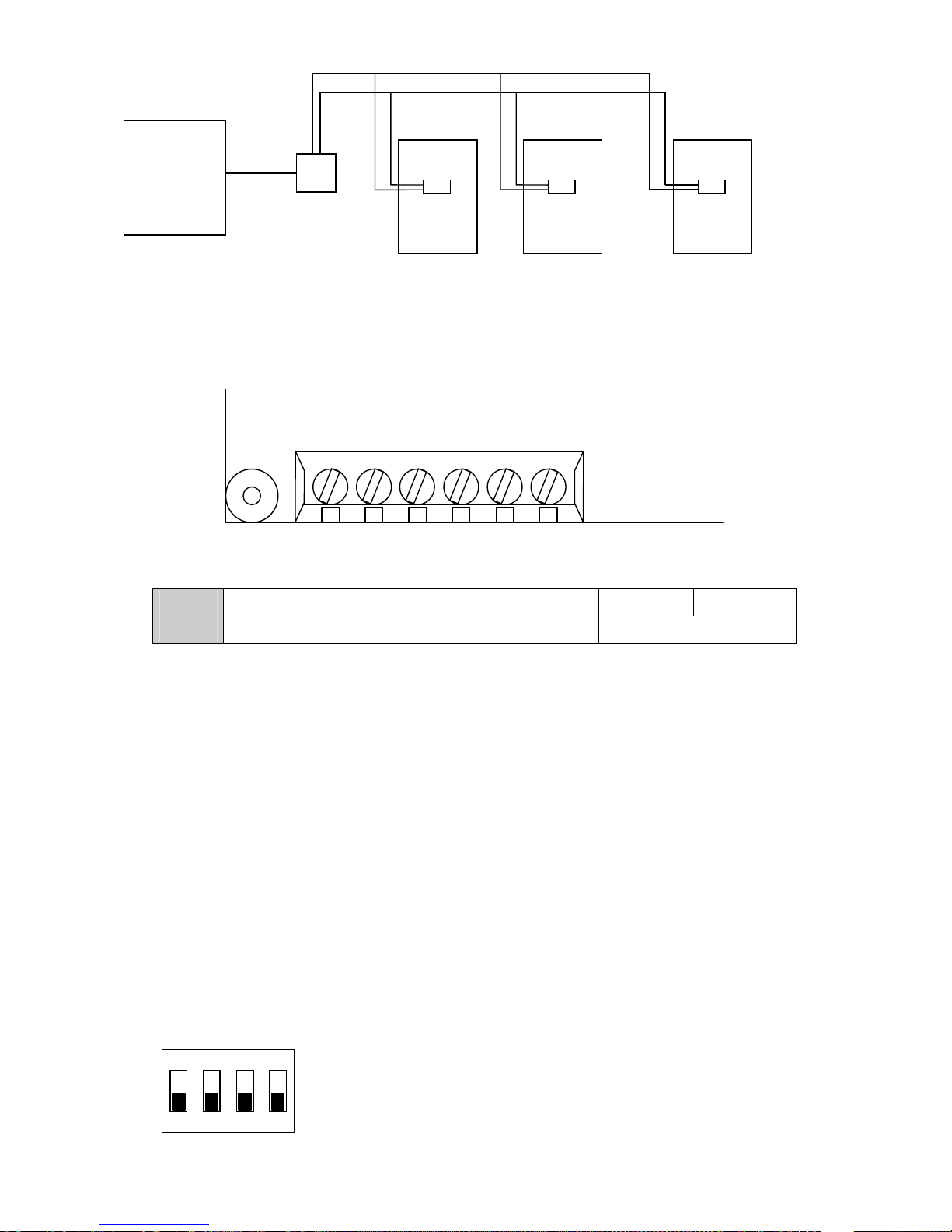

SV-iP5A/iV5 inverter can be controlled and monitored by the sequence program of the PLC or other

master module. The option card provides a terminal block for an RS-485/Modbus-RTU interface. Drives or

other slave devices may be connected in a multi-drop fashion on the RS-485/Modbus-RTU network and

may be monitored or controlled by a single PLC or PC.

Inverter can be easily applicable to Factory Automation because operation and monitoring is available by

User-program.

* Parameter setting and monitoring is available via computer.

(Ex: Freq. Command, Run/Stop etc.)

* Interface type of RS485 reference:

1) Allows the drive to communicate with any other computers.

2) Allows one computer to control up to 31 drives with multi-drop link system.

3) Noise-resistant interface.

Users can use any kind of RS232/485 converters. The specifications and performances of converters

depend on the manufacturers, but the basic functions are the same. Refer to the converter manual for

detailed specifications and instructions on how to use.

Before Installation

Before installation and operation, this manual should be read thoroughly. If not, it could cause personal

injury or damage other equipment.

SPECIFICATION

Performance specification

Items Specifications

Communication method RS485 (RS232/485 converter)

Transmission form Bus method, Multi-drop Link System

Applicable inverter SV-iP5A/iV5 series

Converter Converter with RS232 card embedded

Number of inverters connected Maximum 31 drives connectable note1)

Transmission distance Max. 1200m (Less than 700m recommended) note2)

note1) The number of inverters to be connected is up to 31.

note2) The specification of length of the communication cable is max. 1200m. To ensure stable

communication, limit its length below 700m.

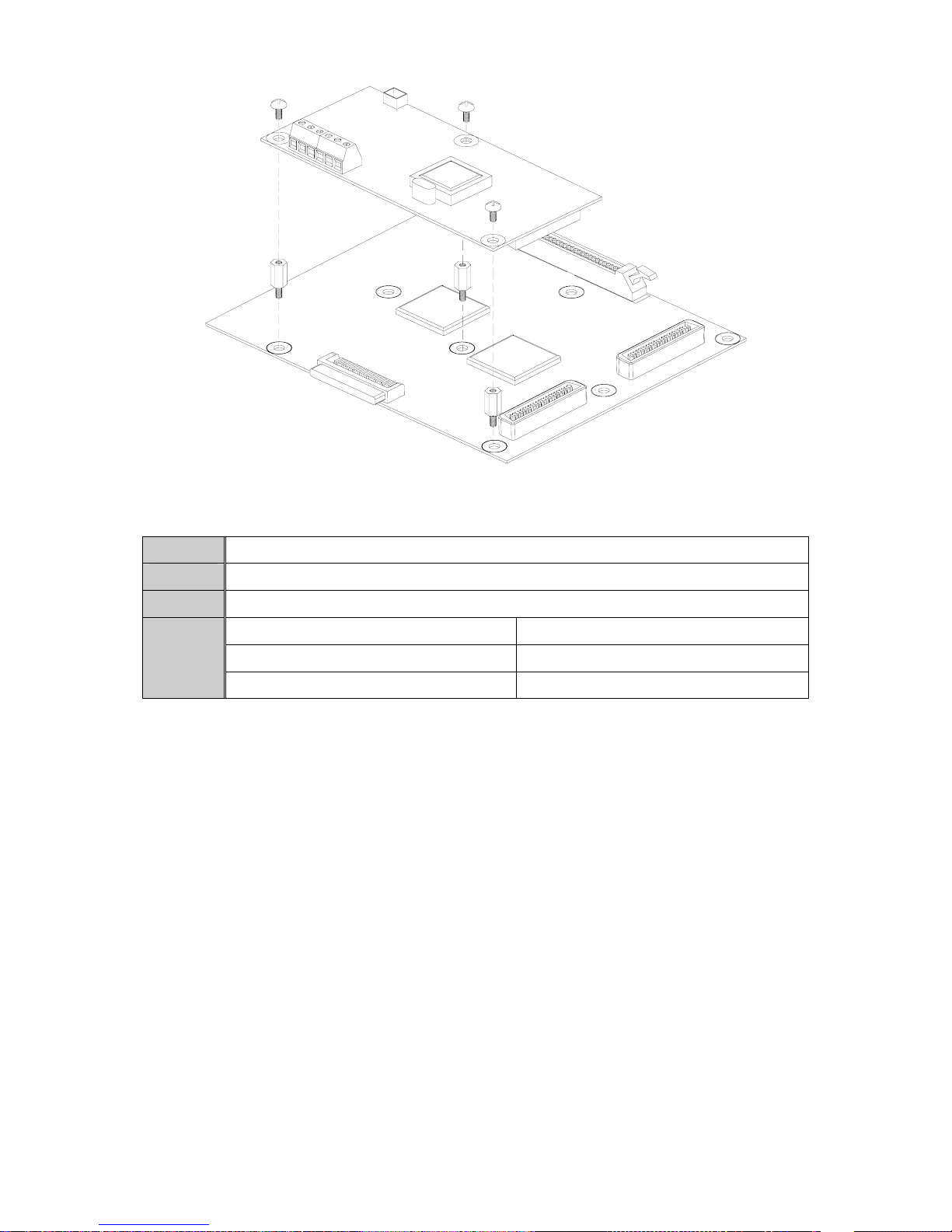

2.2. Hardware Specifications

Items Specifications

Installation Use option connector on the inverter control board

Control B/D From inverter power supply

Power Supply

Comm. B/D From control board (insulated)