Warranty

Product is covered by 2 years Limited Warranty (from the date of purchase). Limited Warranty covers

any defects in material or manufacturing defects under normal use and maintenance. We reserve the

right not to accept the claim in the case of mechanical damage that could be related to the defect of

the product or if the product was disassembled by unauthorized service.

This limited warranty also does not cover any problem that is caused by conditions, malfunctions or

damage not resulting from defects in material or workmanship.

During warranty period, we will repair or replace defective product or defective parts. To obtain

warranty service, you must first contact us to determine the problem and the most appropriate solution

for you.

Safety notice

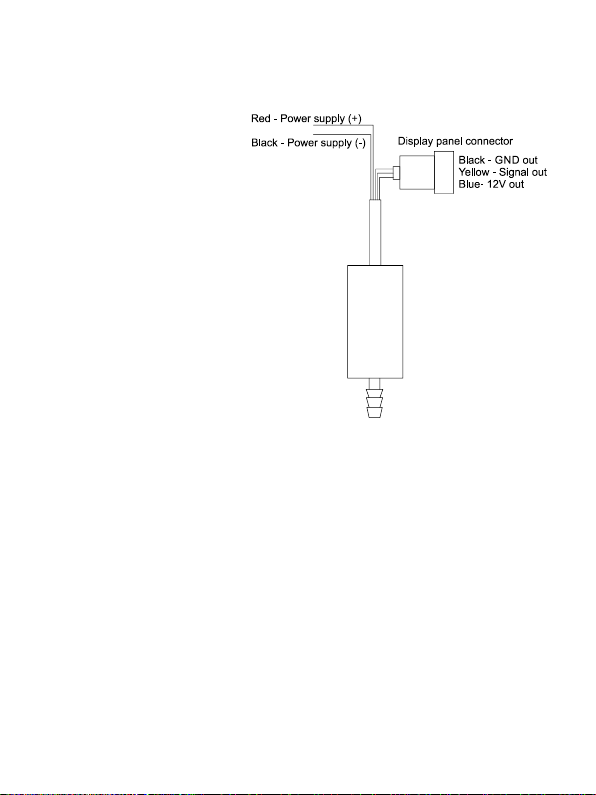

This device should be installed by specialized garage or service. Inappropriate mounting or electrical

connection may result in damaging this or any other electrical devices in the motorcycle. Improper

installation of fuel hoses can cause the fuel to leak and a fire resulting in damage the motorcycle and the

owner’s health.

Device is not approved for use at public roads. You use it at your own risk and responsibility.

Troubleshooting

If you obey all the instructions, this fuel gauge should work properly without problems. In case of any

problems, feel free to contact us.

-If the gauge doesn’t show anything on the display, check out all the connections of the device.

-If the gauge shows nonsense and is calibrated correctly, try checking, if you filled up the fuel hoses

like explained on page three.

-Wrong data display is often caused by dirty fuel strainer in the fuel tank, dirty fuel filter if the

gauge is connected after it or just marginally opened fuel cock. In case of problems, try to

check/replace these parts. This fault is often represented by the amount of fuel dependant on

engine revs. Pressure sensor fail is very improbable –problems are usually caused by something

else.

If nothing helps, contact us.