Contents

iii

CONTENTS

1Introduction ................................................................................................ 1

1.1 About the HPT63 ................................................................................. 1

1.2 Unit Specification ................................................................................. 1

2Safety & EMC............................................................................................. 3

2.1 Wiring Installation................................................................................. 3

2.2 Noise suppression................................................................................ 3

3Installation.................................................................................................. 5

3.1 Head-mounted Version Mechanics ...................................................... 5

3.2 Wall-mounted Version Mechanics........................................................ 7

3.3 Dip Tube Assembly.............................................................................. 8

3.4 Connections ......................................................................................... 9

3.5 Digital Inputs ...................................................................................... 12

4User Interface .......................................................................................... 13

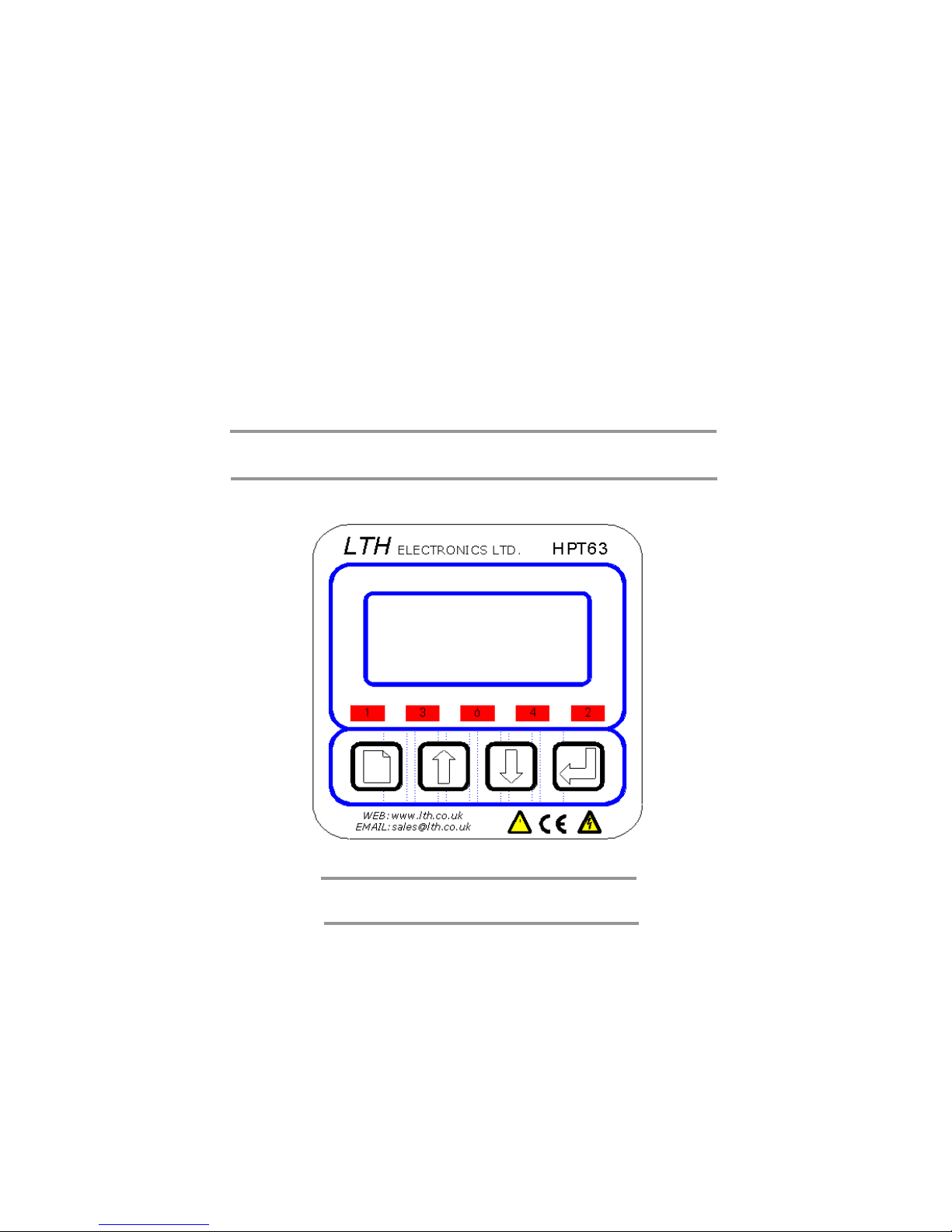

4.1 The Front Panel ................................................................................. 13

4.2 The Menu System.............................................................................. 14

4.3 Unit Configuration .............................................................................. 15

4.4 Number entry ..................................................................................... 16

4.5 Error Messages.................................................................................. 16

5Main Display............................................................................................. 17

6Menu Access ........................................................................................... 18

6.1 Changing the Access Code................................................................ 18

7Parameters .............................................................................................. 19

7.1 Units................................................................................................... 19

7.2 Electrode Type................................................................................... 20

7.3 Temperature Input ............................................................................. 20

7.4 Simulated Input .................................................................................. 21

8Set Point Relays....................................................................................... 22

8.1 Set Point Source ................................................................................ 23

8.2 Set Point Trigger ................................................................................ 23

8.3 Set Point Mode .................................................................................. 24

8.4 Dose Alarm Timers ............................................................................ 25

8.5 Alarms................................................................................................ 25

8.6 Cleaning............................................................................................. 25

9Current Output ......................................................................................... 26

9.1 Input................................................................................................... 26

9.2 Select Output ..................................................................................... 26

9.3 Zero & Span....................................................................................... 26

9.4 Proportional Control ........................................................................... 27

9.5 Error Condition................................................................................... 27

10 Calibration................................................................................................ 28