PAD-CLIMATE-SYSTEM

Assembly instruction and operators manual

Table of Contents

1. INTRODUCTION

BRIEF DESCRIPTION OF LUBING PAD-CLIMATE-SYSTEMS ........................................... 41.1.

PREFACE TO THE MANUAL .......................................................................................... 41.2.

2. GENERAL INFORMATION

WARNINGS AND SYMBOLS .......................................................................................... 52.1.

DESIGNATED USE ...................................................................................................... 62.2.

GENERAL SAFETY GUIDELINES -INTENDED USE ........................................................... 62.3.

OBLIGATIONS ............................................................................................................ 72.4.

WARRANTY AND LIABILITY .......................................................................................... 72.5.

ELECTRICAL SYSTEM ................................................................................................. 82.6.

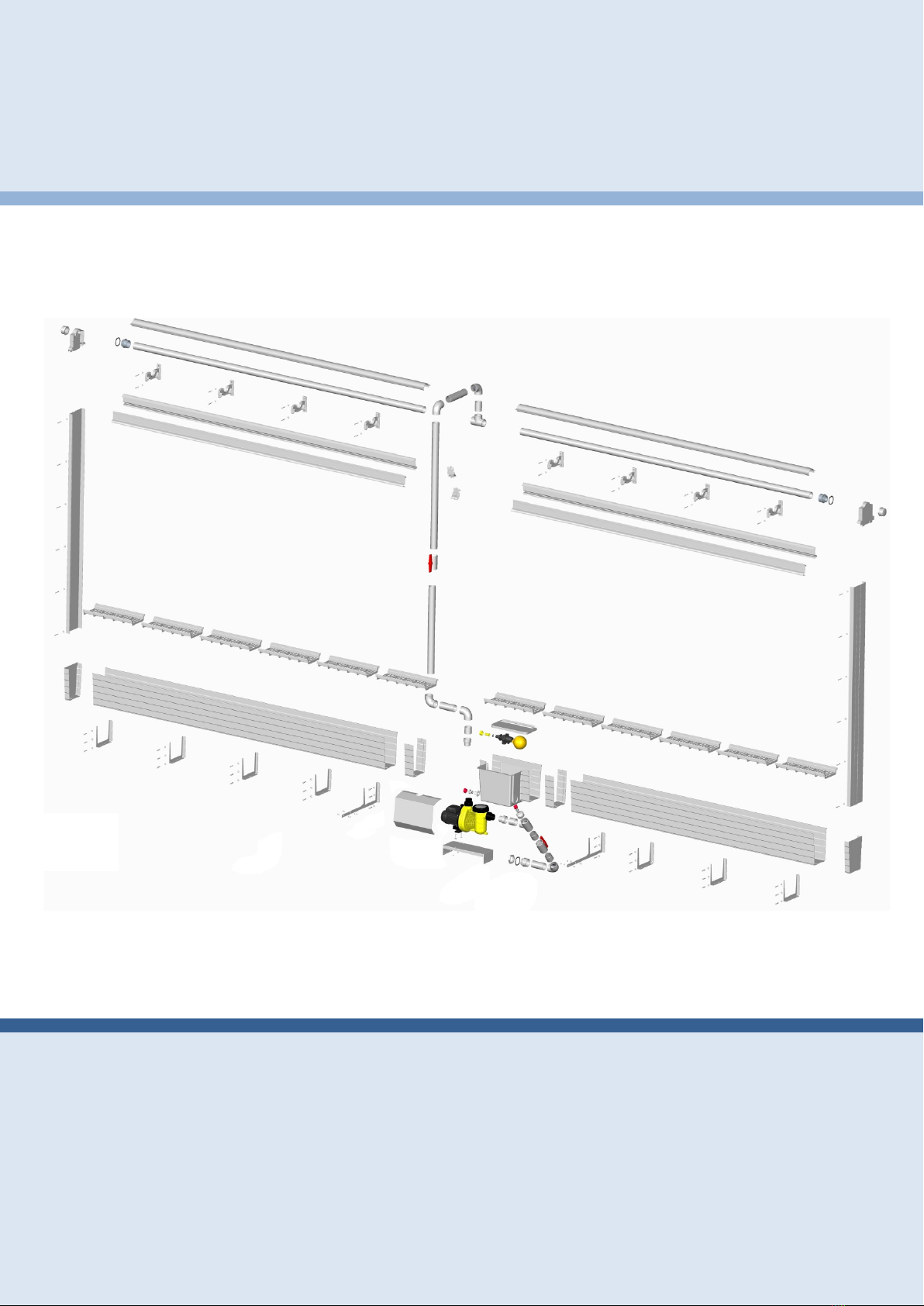

3. ASSEMBLY

ASSEMBLY INFORMATION ........................................................................................... 83.1.

PAD LOCATION IN BUILDING ........................................................................................ 83.2.

ASSEMBLY ORDER ..................................................................................................... 93.3.

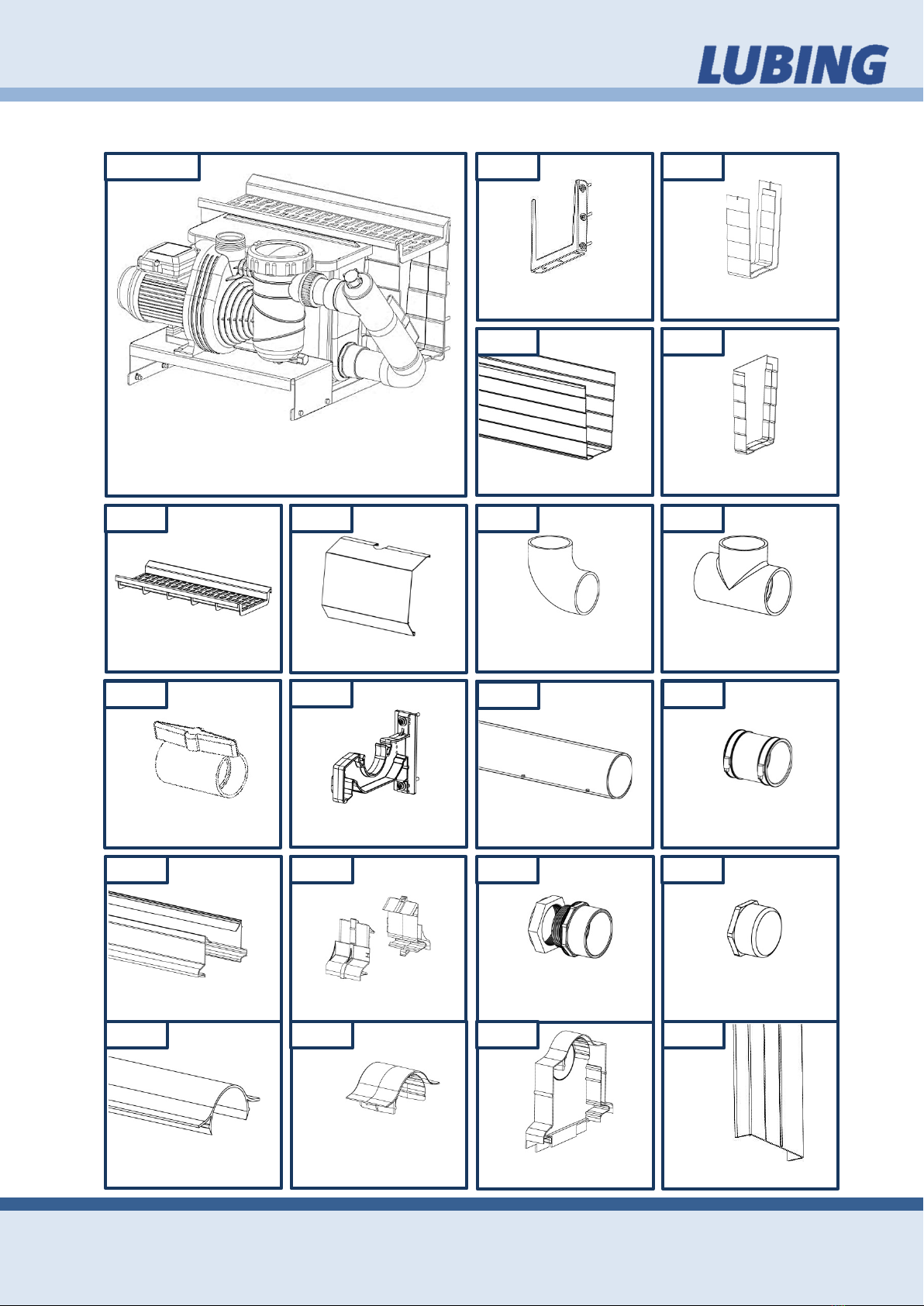

SPARE PARTS............................................................................................................ 93.4.

RECOMMENDED TOOLS .............................................................................................. 93.5.

INSTALLATION PROCEDURES ...................................................................................... 93.6.

ASSEMBLING ............................................................................................................103.7.

3.7.1. Bracket for Watergutter ............................................................................................ 11

3.7.2. Watergutter ............................................................................................................... 12

3.7.3. Glued connections.................................................................................................... 12

3.7.4. Top Bracket .............................................................................................................. 14

3.7.5. Supply Unit ............................................................................................................... 14

3.7.6. Water Distribution Pipe............................................................................................. 15

3.7.7. Pad Guide................................................................................................................. 16

3.7.8. Covers ...................................................................................................................... 17

3.7.9. Deflector ................................................................................................................... 17

4. OPERATING INSTRUCTIONS

CONCEPT OF EVAPORATIVE COOLING ........................................................................184.1.

PRIOR START UP ......................................................................................................184.2.

OPERATING..............................................................................................................194.3.

TO REMOVE THE PAD GUIDE .....................................................................................204.4.

5. TECHNICAL DATA

CENTRIFUGAL-PUMP LUBING AQUA 11 ...................................................................215.1.

5.1.1. General technical data.............................................................................................. 21

5.1.2. 1 ~ 230 V / 50 Hz...................................................................................................... 21

5.1.1. 1 ~ 230 V / 60 Hz...................................................................................................... 21

5.1.2. 3 ~ Y/∆ 400 V / 50/60Hz ........................................................................................... 21