3

Contents

1. APPLICATION ................................................................... 5

2. MODULE SET.................................................................... 6

3. BASIC REQUIREMENTS, OPERATIONAL SAFETY ........................... 7

4. INSTALLATION .................................................................. 8

4.1. Mounting ......................................................................................8

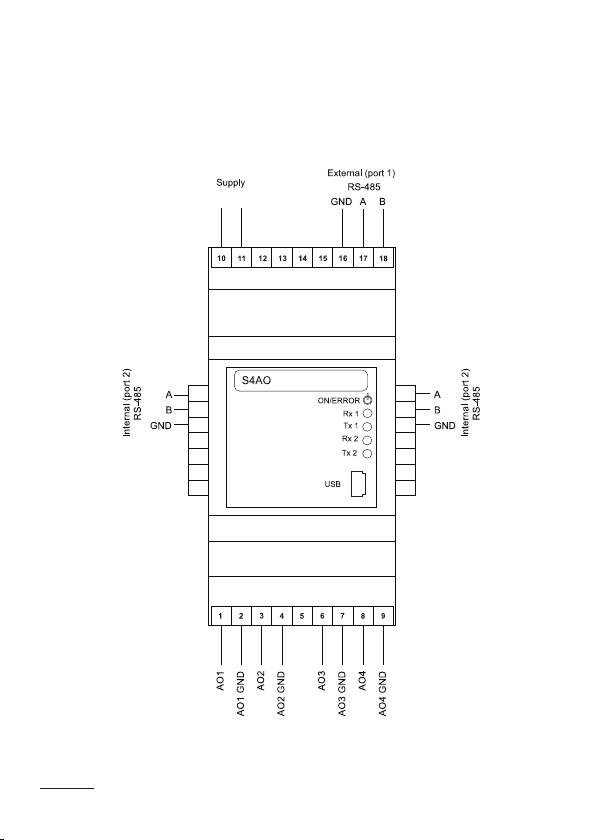

4.2. ExtErnal ConnECtion DiagraMs ...........................................10

4.3. latEral bus................................................................................12

5. OPERATION ................................................................... 13

5.1 Configuration............................................................................13

5.2 slavE opErations ......................................................................13

5.3 MastEr opErations...................................................................14

5.4 CoopEration with othEr DEviCEs (latEral bus)................15

5.5 CountErs .....................................................................................16

5.6 inDiviDual CharaCtEristiC ......................................................18

5.7 short CirCuits ...........................................................................19

5.8 tiMEout ........................................................................................19

5.9 DEviCE Configuration using E-Con prograM......................23

5.9.1 Configuration paraMEtErs ..........................................25

5.9.2 status valuE.....................................................................29

5.9.3 ConfigurED valuEs..........................................................30

6. SERIAL INTERFACES ......................................................... 31

6.1 rs-485intErfaCEs – list of paraMEtErs...............................31

6.2 usb intErfaCE – list of paraMEtErs.....................................32

6.3 Map of s4ao MoDulE rEgistErs..............................................32

7. BEFORE DECLARING A DAMAGE ........................................... 50

8. SOFTWARE UPDATE ......................................................... 51

9. TECHNICAL DATA ............................................................ 53

10. ORDERING CODE ............................................................ 56