AB217 LUXEON HR30 Application Brief 20160504 ©2016 Lumileds Holding B.V. All rights reserved. 5

2.2 Surface Finishing

Lumileds recommends using a high temperature organic solderability preservative (OSP) or electroless nickel immersion

gold (ENIG) plating on the exposed copper pads.

2.3 Minimum Spacing

Lumileds recommends a minimum edge to edge spacing between LUXEON emitters of 0.5 mm. Placing multiple LUXEON

emitters too close to each other may adversely impact the ability of the PCB to dissipate the heat from the emitters.

2.4 PCB Substrate Selection and Design

Table 1 provides a summary of various relevant performance characteristics of common PCB substrates to aid material

selection. Specic PCB design considerations for each substrate material are summarized below.

Table 1: General PCB substrate characteristics for consideration when designing a PCB for LUXEON HR30 emitter.

FR-4/CEM-3 MCPCB

Cost Low to medium Medium

PCB thermal conductivity performance Low to high (FR4 with lled and capped

vias but with increase cost) High

LED assembly packing density (thermal

resistance consideration)

Generally suitable for low density

application with a large spacing between

LEDs and/or low operating currents

Suitable for high density application with

close spacing between emitters

Dielectric withstand voltage (top copper

to bottom of substrate) Extremely high (>20kV/mm)

Depends on dielectric material thickness

and its property. Typically 4kV for 100um

thick.

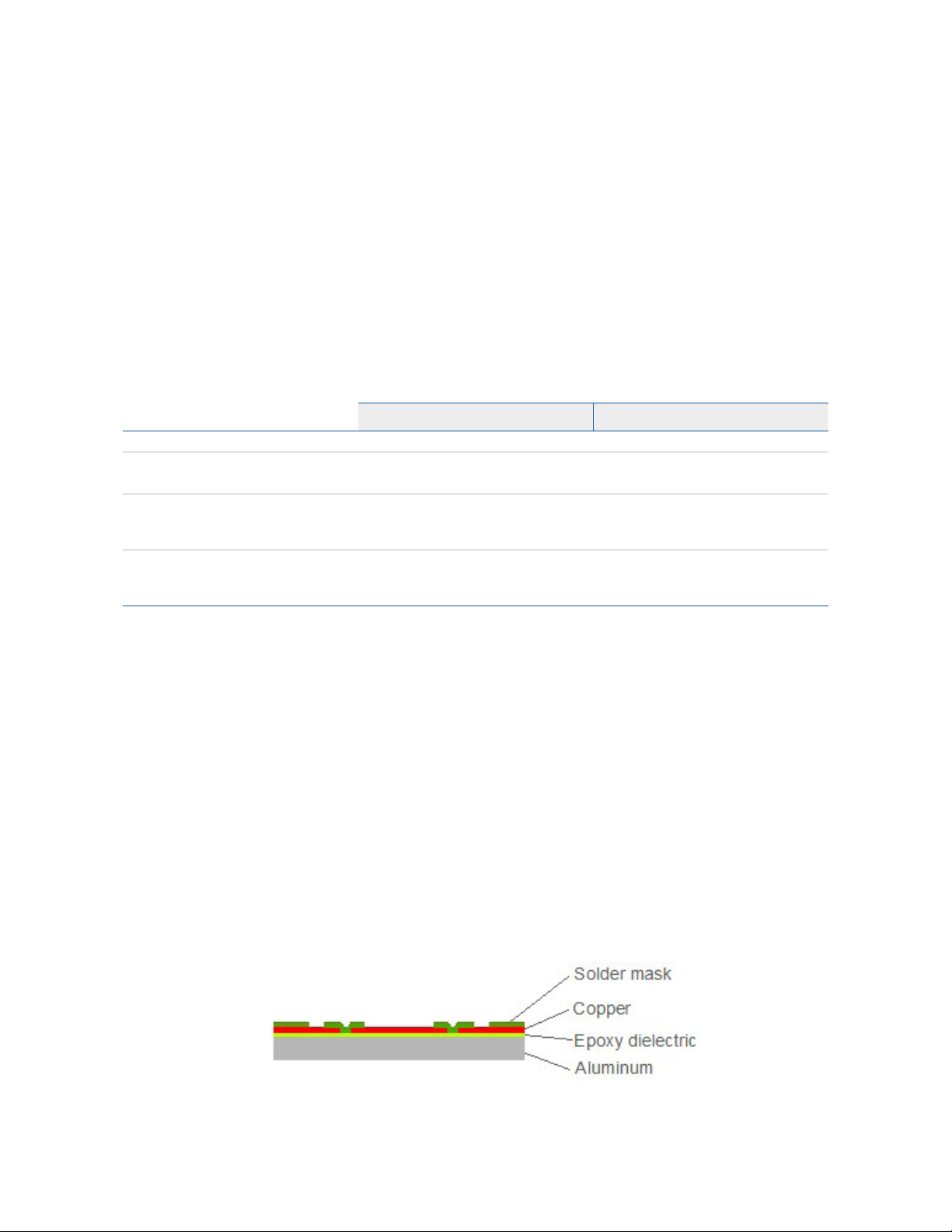

Metal Core PCB

The most common MCPCB construction consists of the following layers (Figure 4):

• A metal substrate, typically aluminum.

• Epoxy dielectric layer. This is the most important layer in the MCPCB construction as it aects the thermal

performance and electrical breakdown strength. The typical thermal conductivity of the dielectric layer on a MCPCB

is around 2Wm-1K-1. A higher value is better for good thermal performance. A thinner dielectric layer is better for

thermal performance but can negatively impact the ability of the MCPCB to withstand electrical insulation test to meet

minimum electrical safety standards as required in certain lighting markets. The typical dielectric thickness layer is

about 100µm.

• Top copper layer. A thicker copper layer improves heat spreading into the PCB but may pose challenges for PCB

manufacturers when fabricating narrow traces or spaces. A thickness of 1oz (35µm) or 2oz (70µm) is common. For

optimum thermal performance on both 1oz and 2oz copper design, the copper area should extend at least 4mm

away from the package outline.

• Use of white solder mask.

Figure 4. MCPCB typical cross section of the three-pad openings with aluminum substrate.