AB172 LUXEON Neo 0.5mm2Application Brief 20180513 ©2018 Lumileds Holding B.V. All rights reserved. 2

Table of Contents

Introduction ...........................................................................1

Scope.................................................................................1

1. Component ........................................................................3

1.1 Reference Document .................................................................3

1.2 Description ..........................................................................3

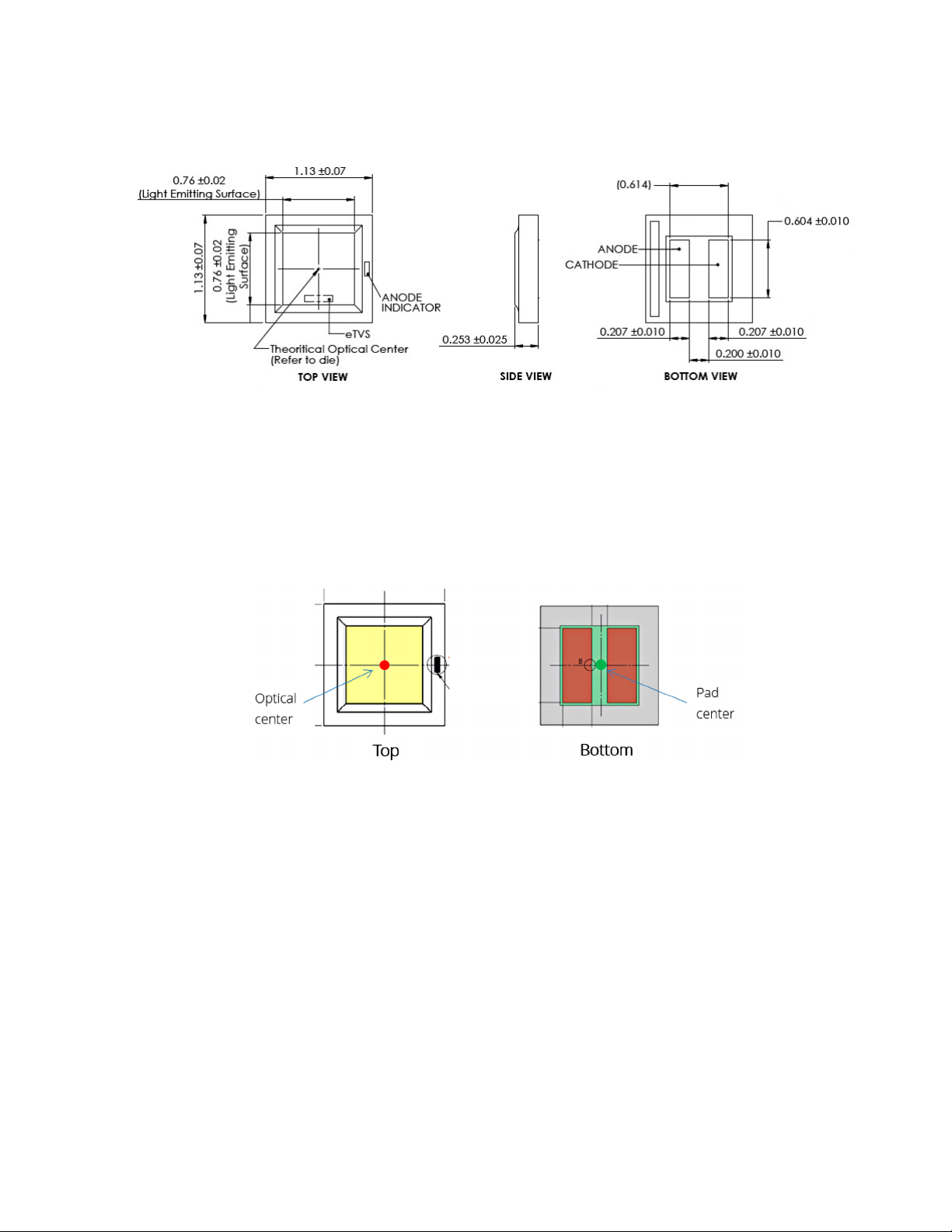

1.3 Form Factor .........................................................................4

1.4 Optical Center .......................................................................4

1.5 Polarity Marking......................................................................5

1.6 Side Coat Geometry ..................................................................5

1.7 Mechanical Files......................................................................6

2. Handling Precautions ................................................................6

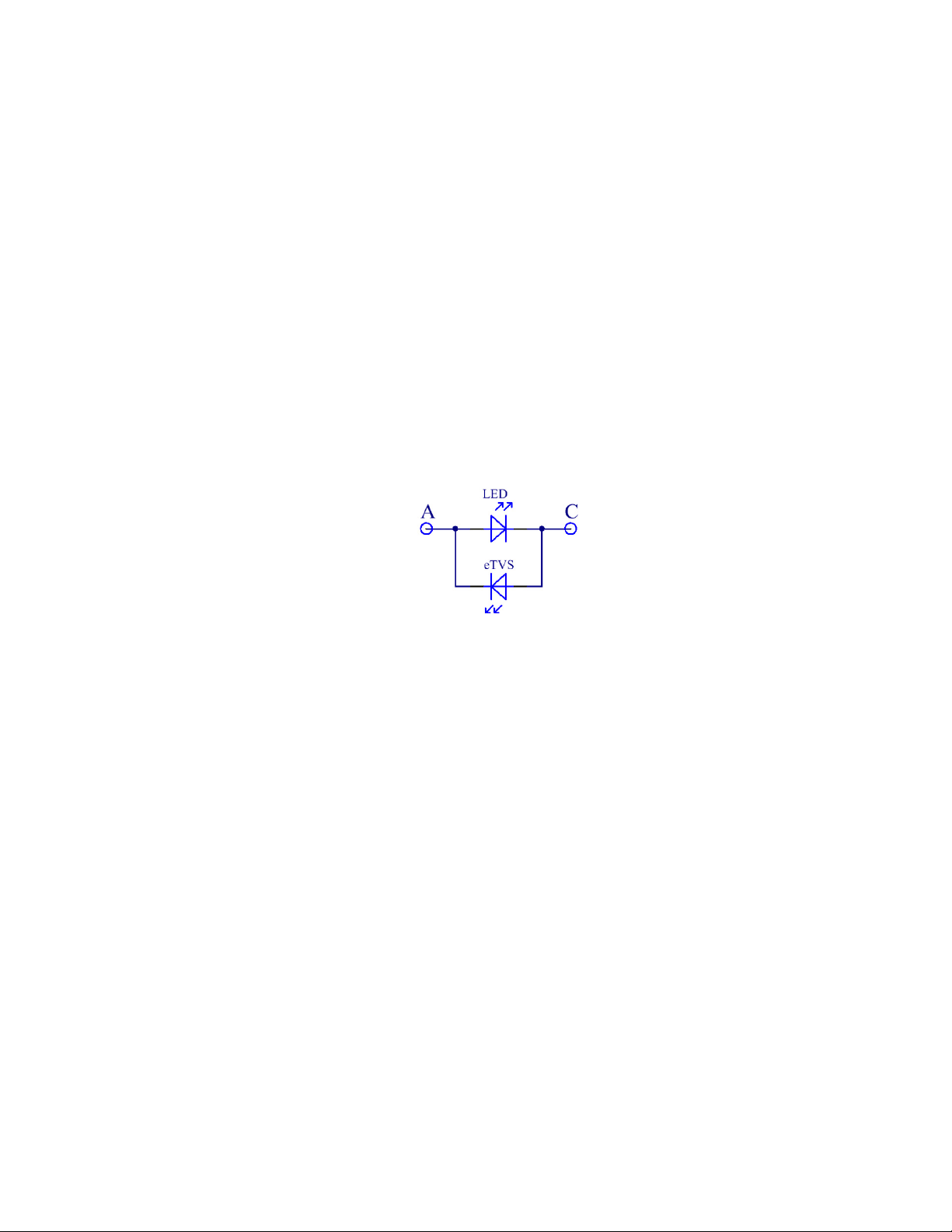

2.1 Electrostatic Discharge Protection (ESD).................................................6

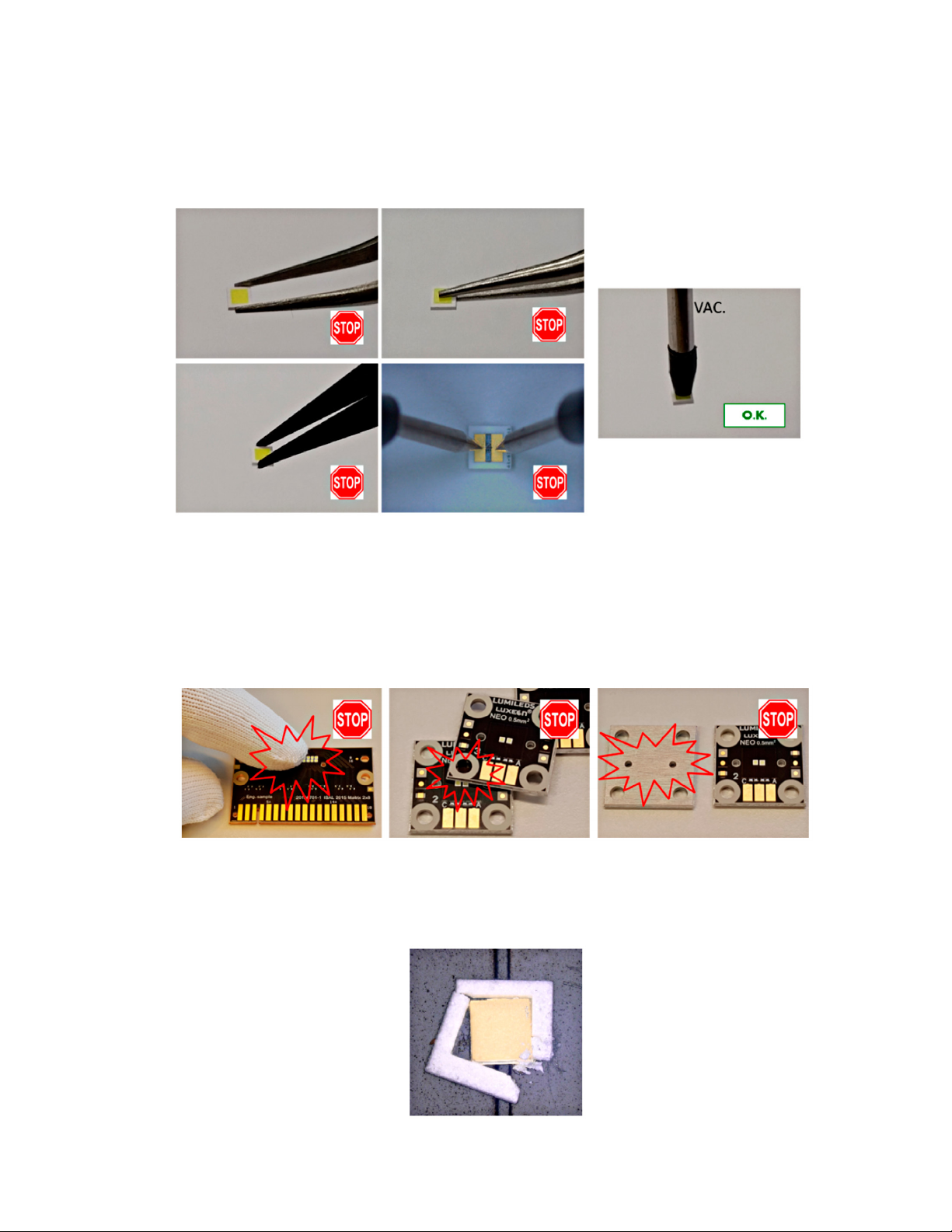

2.2 Component Handling .................................................................6

2.3 Cleaning ............................................................................8

3. Printed Circuit Board ................................................................8

3.1 PCB Requirements ...................................................................8

3.2 Footprint and Land Pattern............................................................8

3.3 Board Fiducial for Solder Mask Dened Footprint ........................................9

3.4 Array Conguration..................................................................10

3.5 Surface Finishing ....................................................................10

3.6 Solder Mask ........................................................................10

3.7 Silk Screen or Ink Printing ............................................................10

3.8 PCB Quality and Supplier.............................................................10

4. Thermal Management ..............................................................11

4.1 Thermal Resistance..................................................................11

4.2 Close-Proximity Thermal Performance .................................................13

4.3 Thermal Measurement Instructions ...................................................13

5. Assembly Process Recommendations and Parameters ..................................15

5.1 Solder Paste ........................................................................15

5.2 Stencil Design.......................................................................15

5.3 Stencil Printing......................................................................16

5.4 Pick and Place Nozzle ................................................................17

5.5 Placement Force/Height Control ......................................................18

5.6 Feed System........................................................................19

5.7 Vision Recognition...................................................................19

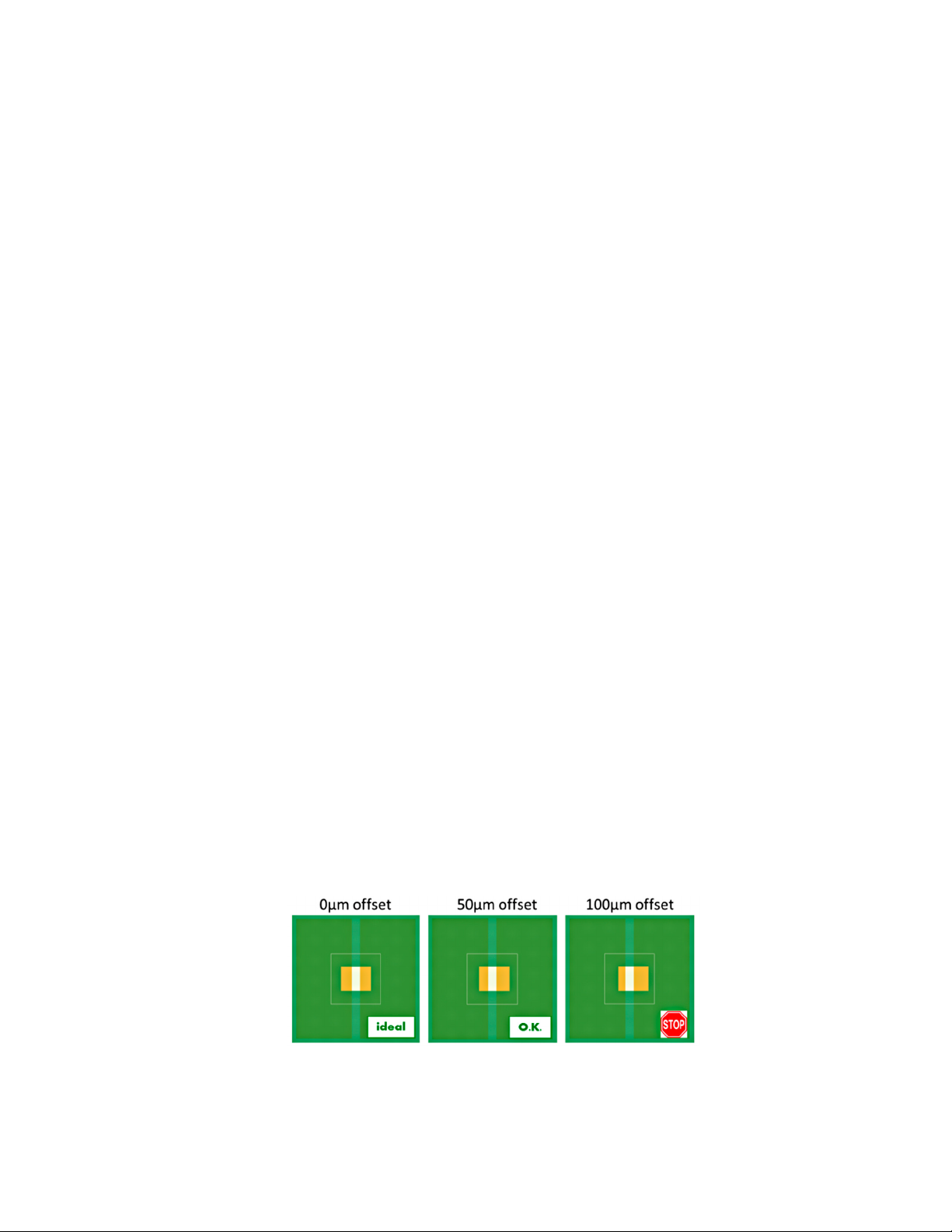

5.8 Placement Accuracy .................................................................20

5.9 Reow Prole .......................................................................20

5.10 Void Inspection ....................................................................21

5.11 Reow Accuracy ...................................................................22

5.12 Electrical Polarity Testing ............................................................23

5.13 Board Handling and Bending ........................................................23

5.14 Packing of Assembled LUXEON Neo Module...........................................24

6. Interconnect Reliability..............................................................24

7. JEDEC Moisture Sensitivity Level......................................................25

8. Packaging Considerations—Chemical Compatibility .....................................26