6

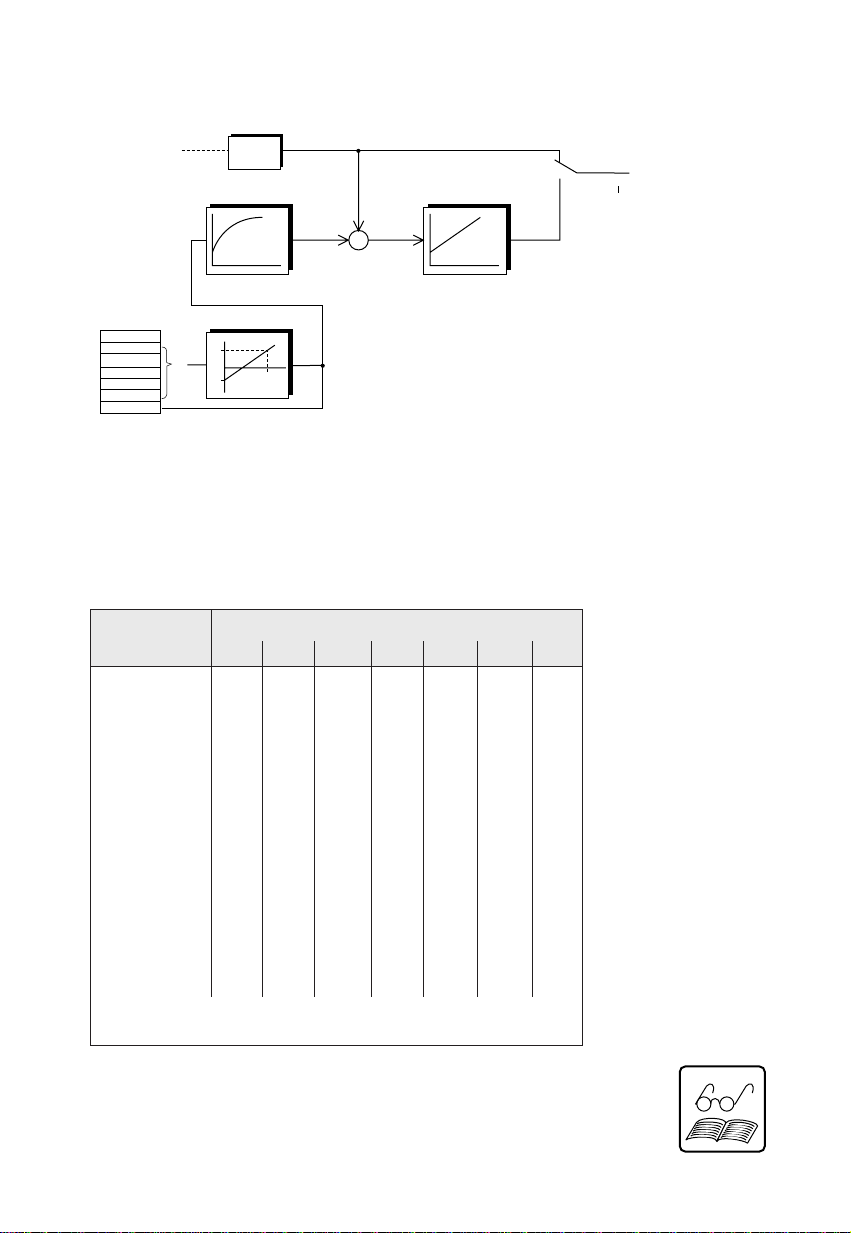

3.2 Technical Controller

The technical controller in theVF1000M andVF1000L controls process

variables such as pressure, temperature, flow rate, jump, etc. It is not

suitable for dynamic process variables such as rotational speed.

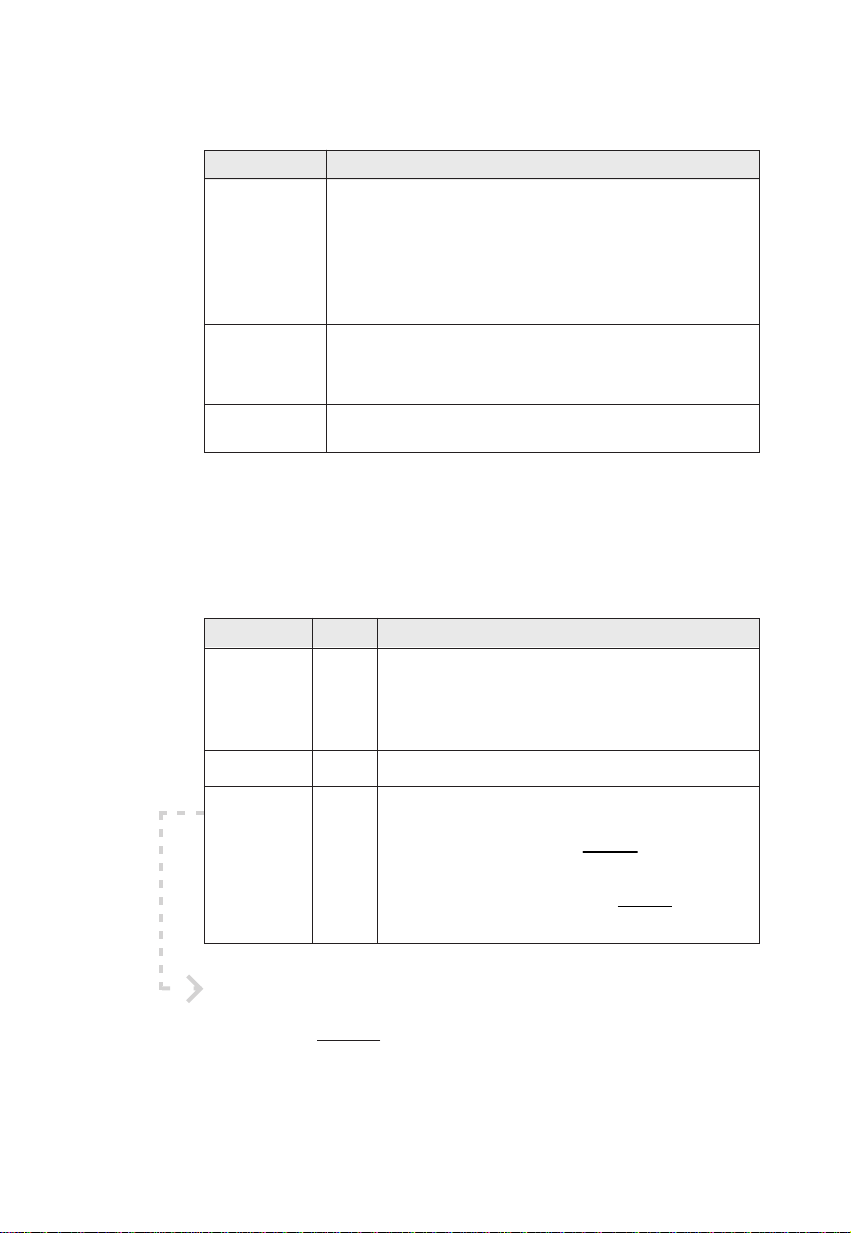

3.2.1 Actual Value Channel

76-CONFI Function

0VAL Technical controllerinactive,functionofFSIN2 with

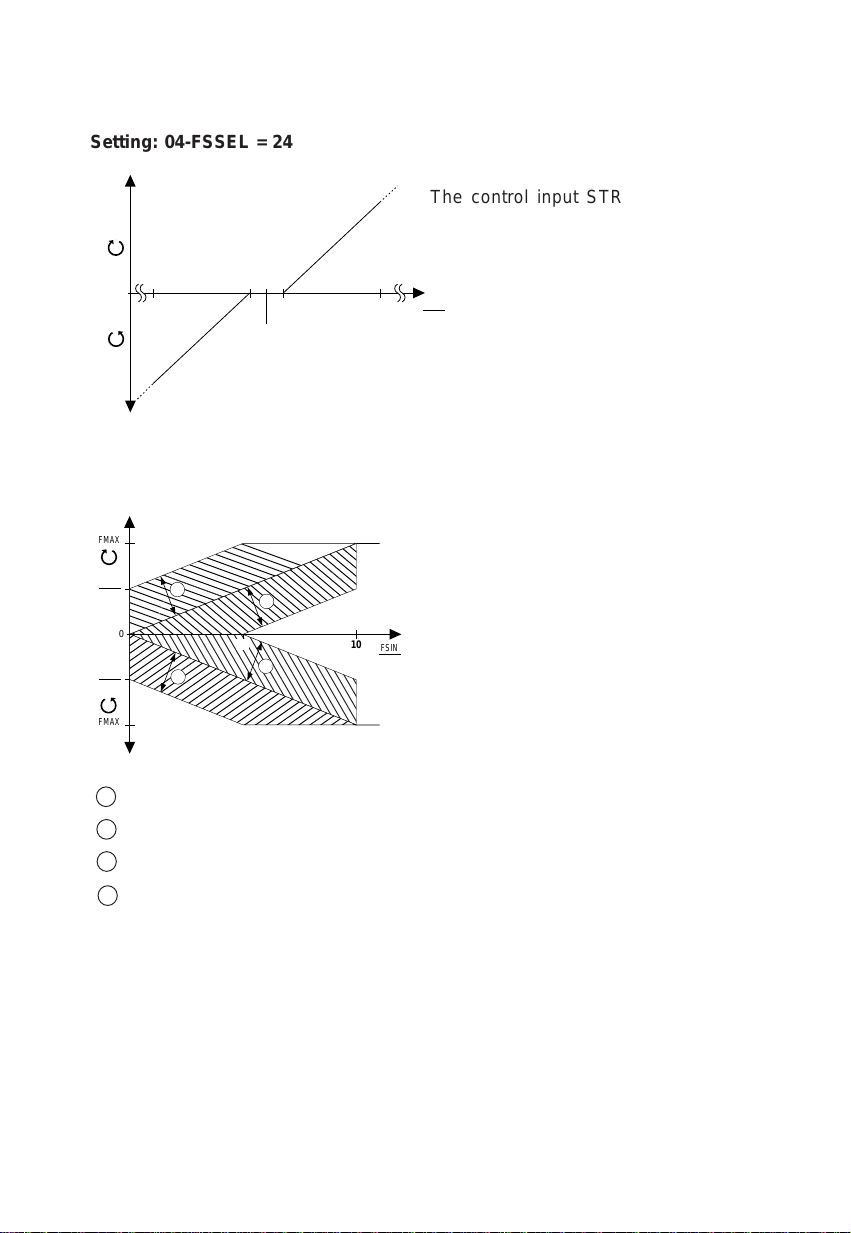

04-FSSEL= 24/25/26

1 Analoginput FSIN

(0 ...10V, 2 ...10 V, 0 ...20 mA, 4 ...20 mA)

2 AnaloginputFSIN2 (±10V)

3 Frequency input (0 ...1 kHz) via FSIN

4 Frequency input FSIN (0 ...10 kHz) via FSIN

5 PWM input (0 ... 100%) via FSIN

6 Serialinterface

Note: Input FSIN can only be assigned once.

3.2.2 Reference Channel

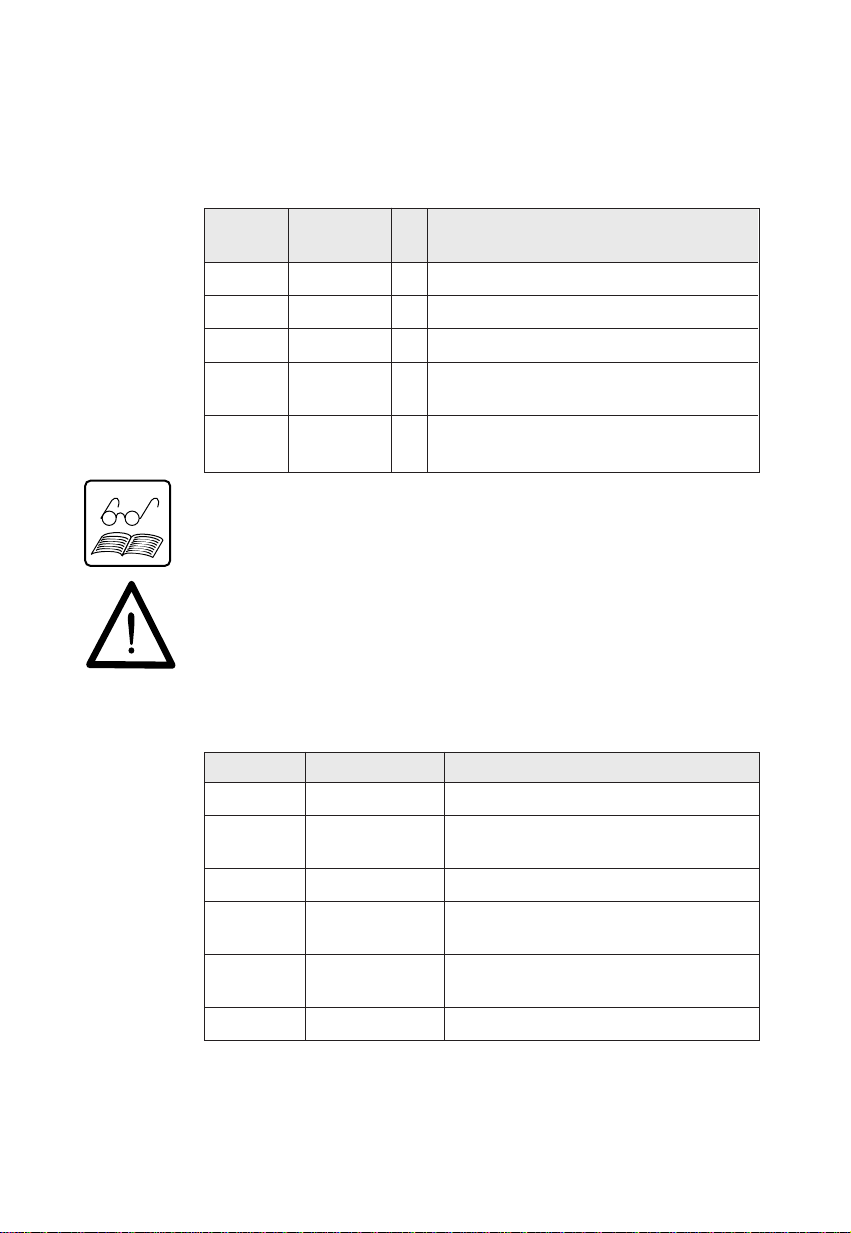

04-FSSEL Referenceselector

0VAL Analog input, 0 ...10V, 2 ...10V, 0 ...20 mA, 4 ...20 mA

3 FSIN as frequency input 0 ... 1 kHz

4 FSIN as frequency input 0 ... 10 kHz

5 FSIN as PWM input 20 ... 100%

6 FSIN as PWM input 0 ... 100%

7 FSINinactive,referenceviaKP100(CTRL menu)

8 Referencevia interface

9 to 16 Reference inputvia fixed frequencies (seeOperationManual)

17to22 CorrectionofanalogreferenceviaS1IND/S2IND

(MOPfunction active)

23 Analog input,directionof actioninverted

24 Analog inputFSIN2, ±10V

25 Analog input FSIN2, 0 ...10V

Note: For more details concerning the functions of analog input FSIN

refer to the relevant Operation Manual.