User Manual CANopen/EtherCAT 5

Contents

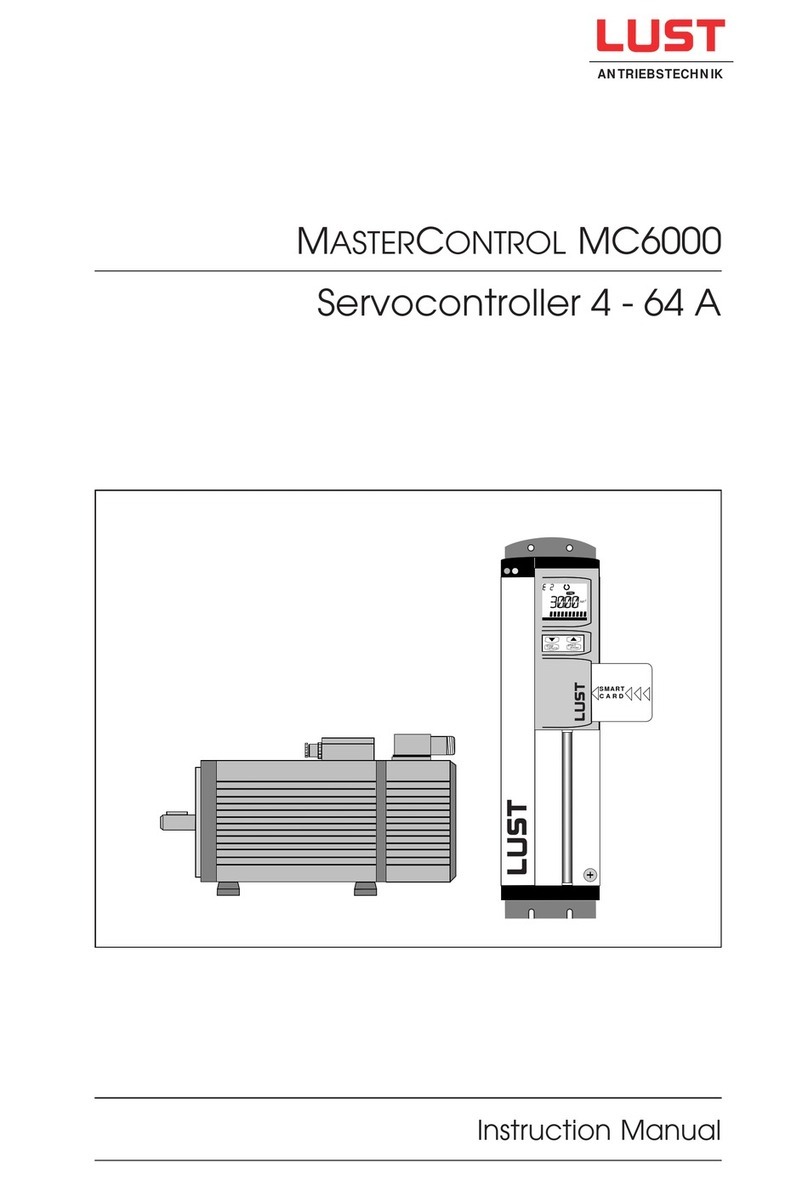

How to use the document ......................................................................................................... 3

Pictograms .............................................................................................................................. 4

1 General Introduction ........................................................................................................... 7

1.1 Measures for your safety ................................................................................................ 7

1.2 Introduction to CANopen............................................................................................... 7

1.3 Introduction to EtherCAT ............................................................................................... 8

1.4 System requirements...................................................................................................... 8

1.5 Further documentation .................................................................................................. 8

2 Mounting and Connection of CANopen............................................................................ 9

2.1 Setting the address ........................................................................................................ 9

2.2 Meanings of LEDs..........................................................................................................10

2.3 Installation ....................................................................................................................11

2.3 Transmission speeds ......................................................................................................13

2.4 Display of the operating states via 7-segment display....................................................13

2.5 Hardware enable...........................................................................................................14

3 Mounting and Connection of EtherCAT ...........................................................................15

3.1 Installation and cabling .................................................................................................15

3.2 Pin assignment of the RJ-45 socket ...............................................................................16

3.3 Meanings of LEDs..........................................................................................................17

3.4 Display of operating states via 7-segment display..........................................................18

3.5 Hardware enable...........................................................................................................18

4 Commissioning and Configuration of CANopen..............................................................19

4.1 Commissioning .............................................................................................................19

4.2 Commissioning sequence..............................................................................................19

4.2.1 Setting the software address and Baud rate........................................................20

4.3 Commissioning instructions...........................................................................................20

4.4 Testing the higher-order controller................................................................................20

4.5 Data handling ...............................................................................................................21

4.5.1 Saving the settings..............................................................................................21

4.5.2 Restoring factory defaults ...................................................................................21

4.6 Commissioning via DRIVEMANAGER ...................................................................................21

4.7 Control functions ......................................................................................................... 22

4.8 Operation mode selection (Modes of operation) .......................................................... 22

4.8.1 Functionality of operation modes....................................................................... 23

5 Commissioning and Configuration of EtherCAT............................................................. 25

6 Setting the Device Parameters for CANopen .................................................................. 27

6.1 Implemented DS301 functionality .................................................................................27

6.1.1 Communication objects ......................................................................................27

6.1.2 Object directory of DS301...................................................................................27

6.2 Parameter channel (Service Data Objects)......................................................................28

6.2.1 Data types...........................................................................................................29

6.2.2 Representation of data types in the control protocol...........................................29

6.2.3 Access to device parameters .............................................................................. 30

6.3 Examples of SDO handling ........................................................................................... 30

6.3.1 Parameter set download .....................................................................................33

6.4 PDO transmission types................................................................................................ 34

6.5 Event-controlled TxPDO transmission............................................................................ 34