8

out of the sphere of influence of the rotating

tool and operate the power tool for a minute

at the highest revolutions. Damaged tools will

usually break within this test period.

• Wear personal safety gear. Depending on the

work you are doing, wear a full-face visor,

visor or protective goggles. If appropriate,

wear a dust mask, ear defenders, protective

gloves or a special apron designed to keep

sanding and material particles away from

you. Your eyes should be protected from the fly-

ing objects that may be generated during various

applications. Dust or breathing masks must be

capable of filtering the dust generated during

operation. If you are expose to loud noise for

extended periods, you may suffer a loss of hear-

ing.

• Ensure that other people are kept a safe dis-

tance from your workplace. Anyone entering

the workplace must wear personal protective

gear. Pieces of the workpiece or broken tools

may fly away and cause injuries even outside the

direct workplace.

• Hold the tool by the insulated handle surfaces

only when you are carrying out tasks during

which is it possible that the tools will come

across hidden power cables or its own cable.

Contact with a power-carrying cable can also

put metal parts of the unit under power and

cause an electric shock.

• Keep the power cable away from rotating

tools. If you loose control of the unit, the power

cable may be cut or caught up and your hand or

arm may be pulled into the rotating tool.

• Clean the ventilation slots of your power tool

regularly. The motor fans draw dust into the

housing and a large deposit of metal dust can

cause electrical hazards.

• Never use power tool near flammable materi-

als. Sparks may set fire to these materials.

• Never bring your hands into the cutting area

when the power tool is running. Contact with

the cutting disc holds a risk of serious injury.

• Never reach behind the cutting disc to hold

the work piece or to remove chips. The dis-

tance between your hand and the operating cut-

ting disc is too small.

• Only guide the work piece as far as the oper-

ating cutting disc. Otherwise there is a risk of

kickback when the cutting disc becomes

jammed in the entering work piece.

• Use the power tool only when the work sur-

face is free from all setting tools, workpiece

parts etc. Objects the come into contact with

the rotating cutting disc may hit the operator at

a high speed.

• Always cut one workpiece at a time. Work

pieces the are stacked or stacked against each

other may block the cutting disc or slide about

when cutting.

• Long work pieces must be supported at the

free end. Freely swinging work piece ends may

cause loss of control.

• Always use a parallel stopper. This improves

the accuracy of the cut and reduces the possibil-

ity of a jammed cutting disc.

• If the cutting disc is jammed or you need to

interrupt your work, switch off the device and

hold it motionless until the disc has come to

a standstill. Never attempt to pull a still oper-

ating cutting disc out of the cut as this may

cause kickback. Investigate and take correc-

tive actions to eliminate the cause of the jam.

• Do not switch the power tool back on as long

as it remains stuck in the work piece. Allow

the cutting disc to achieve the full revolutions

before you continue to cut carefully. Other-

wise, the disc may get caught, jump out of the

work piece or cause kickback.

• After switching off the unit, do not attempt to

stop the cutting disc by applying pressure

from the side. Touching the cutting disc may

lead to injuries.

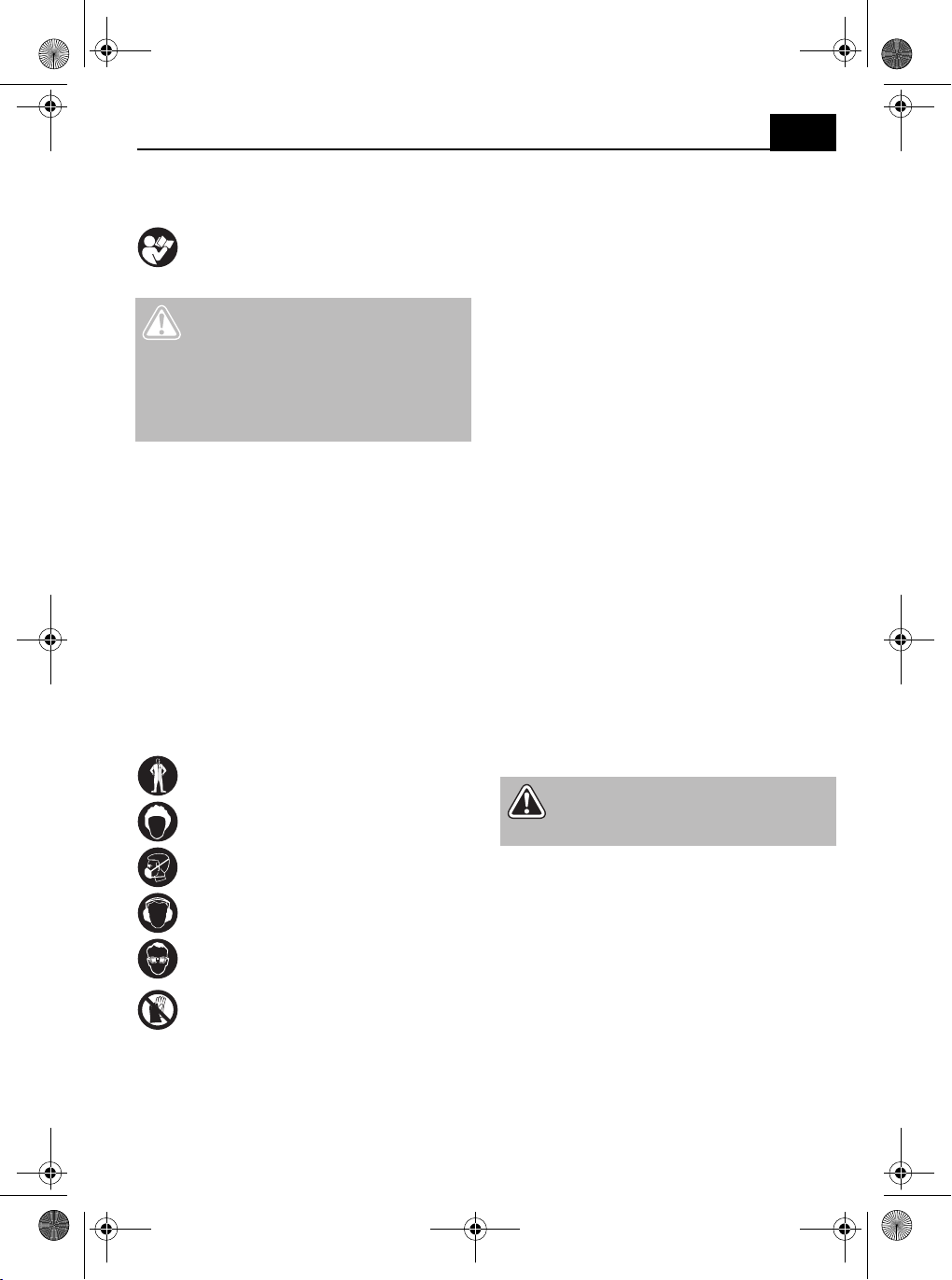

• Use the electric tool always with the enclosed

earth fault circuit interrupter (FI switch).

Check the function of the FI switch before

every use. The FI switch does not protect

against direct touching of electric conductor.

• Never use the electric tool without cooling

water. Check the cooling water level before

every use. A dry run can cause failure of the tool

and thus lead to injuries.

• Do not pull the mains plug if this or the outlet

is wet. First turn off the current by taking out of

the fuse and/or with the circuit breaker of the

respective circuit. Pull first the plug and then test

the extension for possible water traces.

• Empty the cooling water container every

transport. Rest cooling water can penetrate into

the electrical motor parts.

Additional safety notes

• Store the unused power tool safely in a dry

place that can be locked. This ensures that the

power tool is not damaged as a result of storage

and the inexperienced persons do not operate it.

• Never leave the power tool before it has come

to a completed standstill. Tools that continue

to operate may cause injury.

• Never use the power tool with a damaged

cable. Do not touch a damaged cable and pull

out the power plug. Damaged cables increase

the risk of electric shock.

• Prevent overheating of the device and the

work piece. Excess heat may damage the tool

and the device.

• Shortly after being used, the tool may be very

hot. Allow a hot tool to cool down. Touching

a hot tool may cause burns.

• Never clean a hot tool with flammable liq-

uids. There is a risk of fire and explosion.

• Wear ear defenders when working. The

effects of noise can result in a loss of hearing.

• Keep the handles dry and free of grease.

Slippery handles can lead to accidents.

• Always comply with the all applicable domes-

tic and international safety, health, and work-

ing regulations. Inform yourself before you start

work about the regulations that apply at the site

of the device.

• Note that the moving parts can also be fitted

behind ventilation openings.

GB

temp.book Seite 8 Dienstag, 5. April 2016 8:13 08