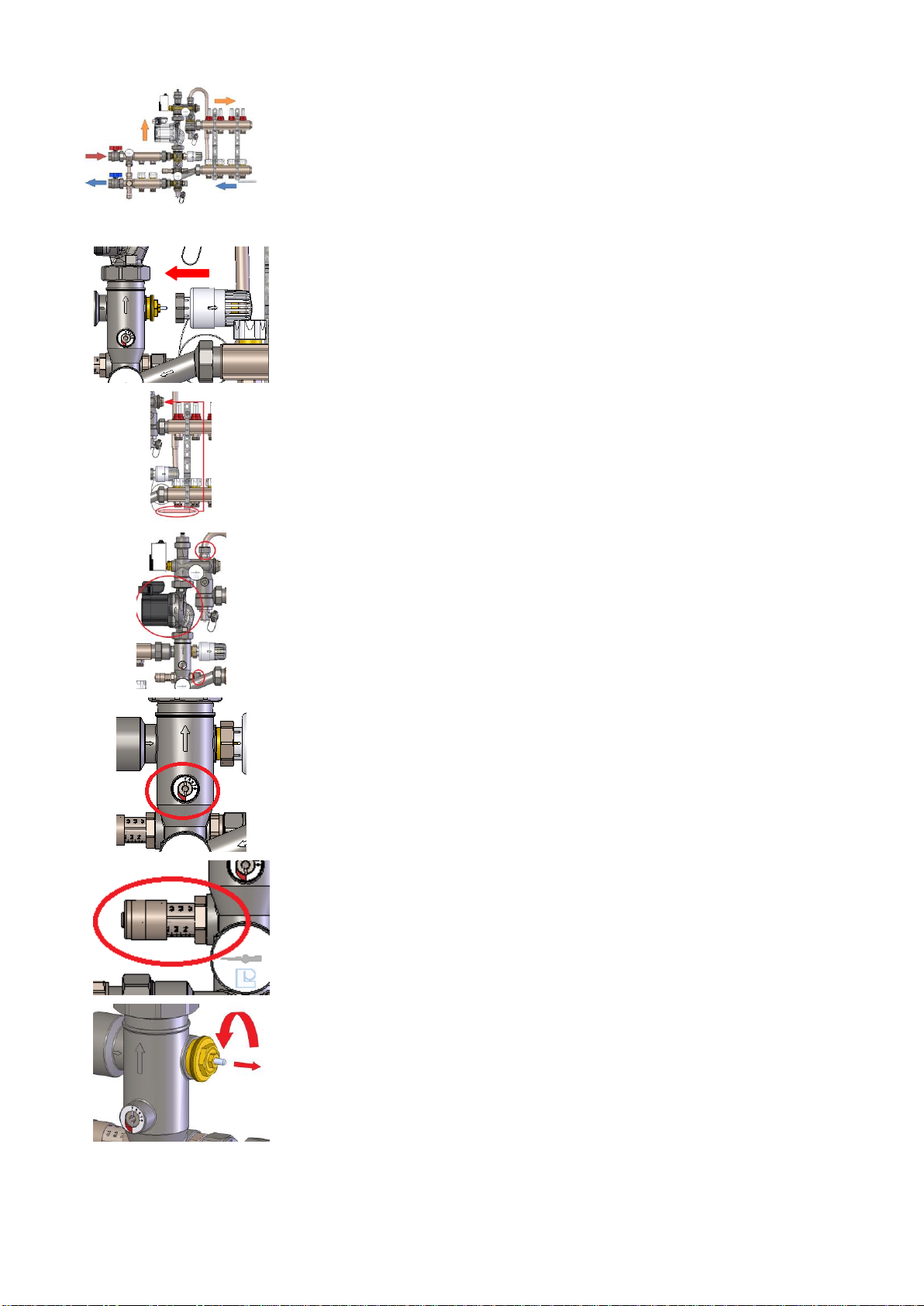

The mixing group GM 1192 is a regulation group which combines a

number of components in a single device able to maintain a pre-set

temperature in the radiant panels circuit of mixed heating systems. The

temperature in the panels is kept constant by a regulating valve which

mixes hot water coming from the boiler with the low temperature one

circulating in the panels. The GM 1192 can be connected directly to

Luxor manifolds for radiant panels by means of a G 1” male fitting with

soft seal. This makes the GM 1192 particularly convenient, since

it can be kept in stock as a modular component.

Moreover, the GM 1192 makes mixed heating systems extremely

flexible, since the regulation group can be adjusted to meet the future

requirements of the secondary circuit. It is therefore possible to expand

the radiant panels system simply by adding outlets, without temperature

or pressure issues downstream of the group.

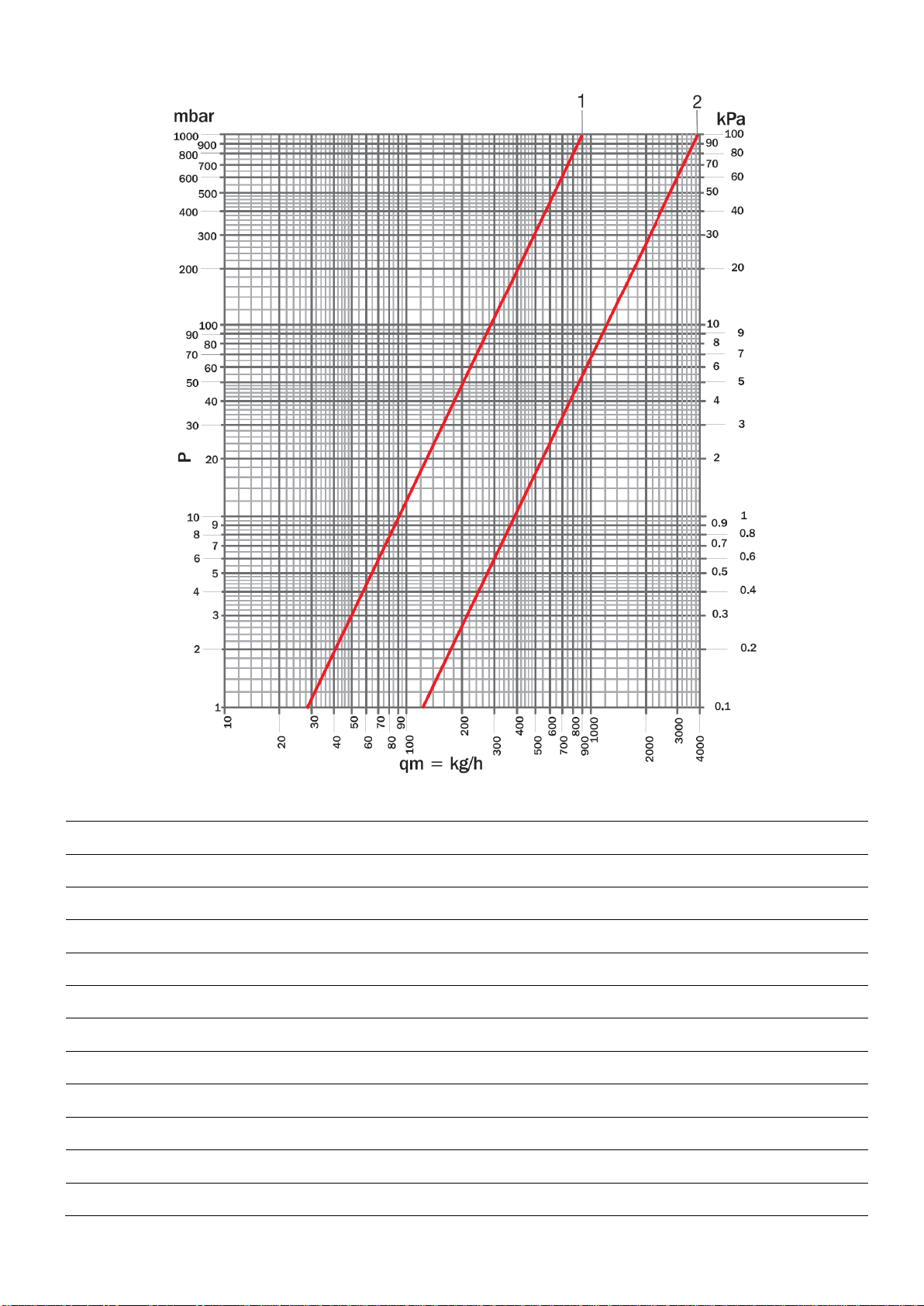

The GM 1192 can be set both to increase the heating capacity

and to balance pressure drops.

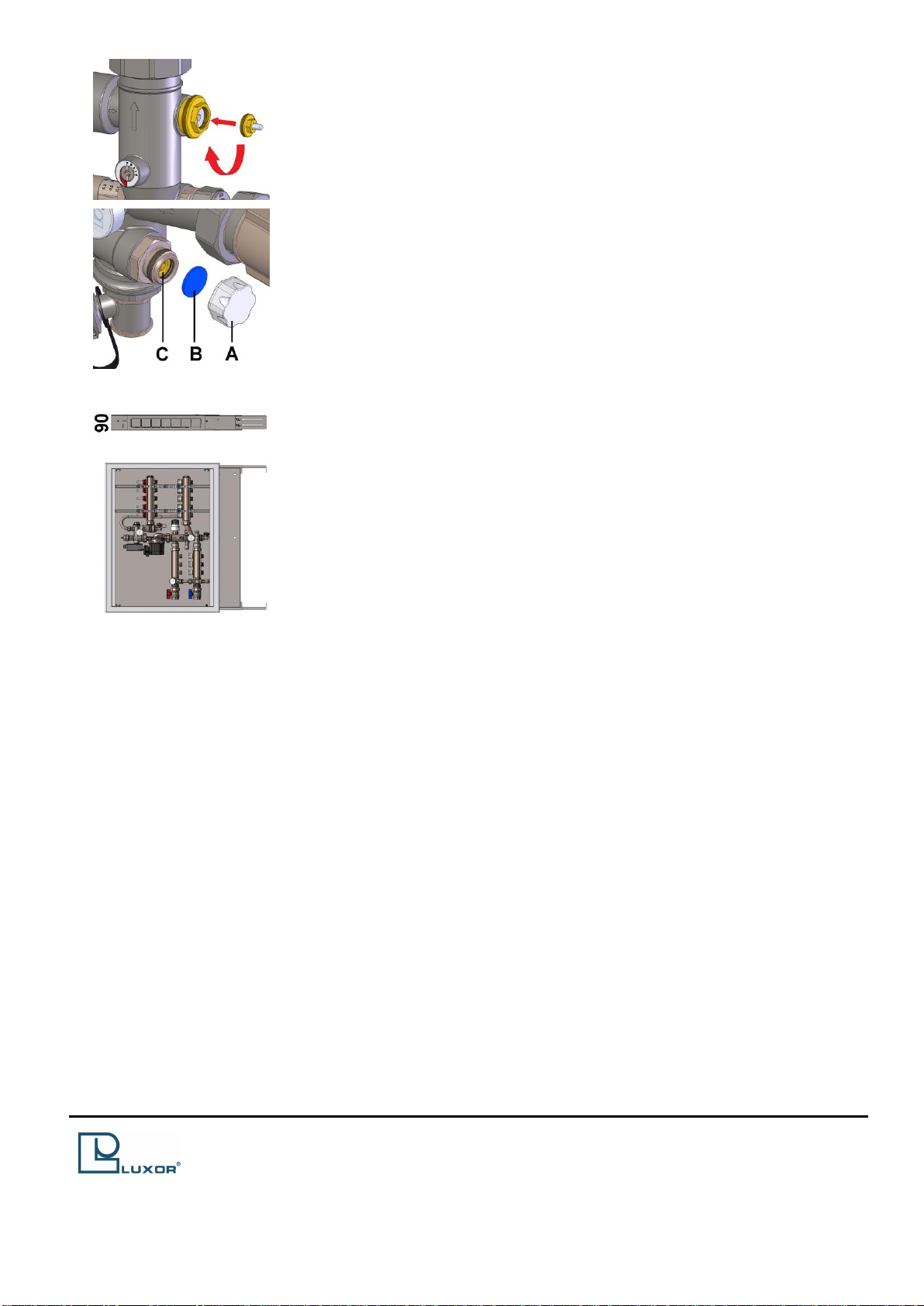

Finally, thanks to its great regulation capacity, the GM 1192 allows to

make the secondary circuit independent from the primary in case of

replacement of important parts of the system, for example when a new

boiler with a different operating principle is installed. By means of the

bypass circuit, the circulation pump can keep on operating at design

conditions.

This type of system can supply a max thermal power of 20 kW with a

temperature of the primary circuit of ≥ 70°C.