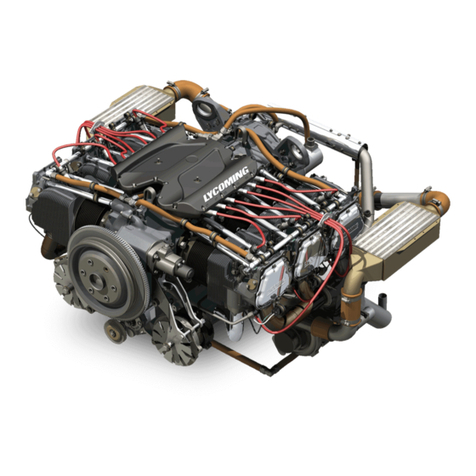

IO-360-N1A Engine Installation and Operation Manual

© 2016 Avco Corporation. All Rights Reserved Table of Contents

February 2016 Page v

TABLE OF CONTENTS

Section Page

Frontal__________________________________________________________________________

Record of Revisions.............................................................................................................................. i

Service Document List.......................................................................................................................iii

Table of Contents................................................................................................................................ v

List of Figures..................................................................................................................................... ix

List of Tables ...................................................................................................................................... xi

Abbreviations and Acronyms .........................................................................................................xiii

Introduction....................................................................................................................................... xv

System Description________________________________________________________________

—System Description ................................................................................................................... 1

—Cylinders................................................................................................................................... 1

—Crankcase.................................................................................................................................. 2

—Ignition System ......................................................................................................................... 2

—Starter........................................................................................................................................ 3

—Fuel Injection System................................................................................................................ 4

—Lubrication System ................................................................................................................... 4

—Cylinder Number Designations................................................................................................. 5

Engine Reception and Lift__________________________________________________________

—Uncrate Procedure for a New, Rebuilt, or Overhauled Engine................................................. 7

—Acceptance Check..................................................................................................................... 7

—Engine Preservative Oil Removal............................................................................................. 8

—Lift the Engine .......................................................................................................................... 8

Requirements for Engine Installation ________________________________________________

—Overview................................................................................................................................... 9

—Step 1. Prepare the Engine........................................................................................................ 9

—Step 2. Supply Interface Items................................................................................................ 14

—Step 3. Remove Components.................................................................................................. 15

—Step 4. Install Aircraft-Supplied Engine Mounts.................................................................... 15

—Step 5. Prepare the Aircraft Engine Harness........................................................................... 15

—Step 6. Make Electrical Interface Connections....................................................................... 15