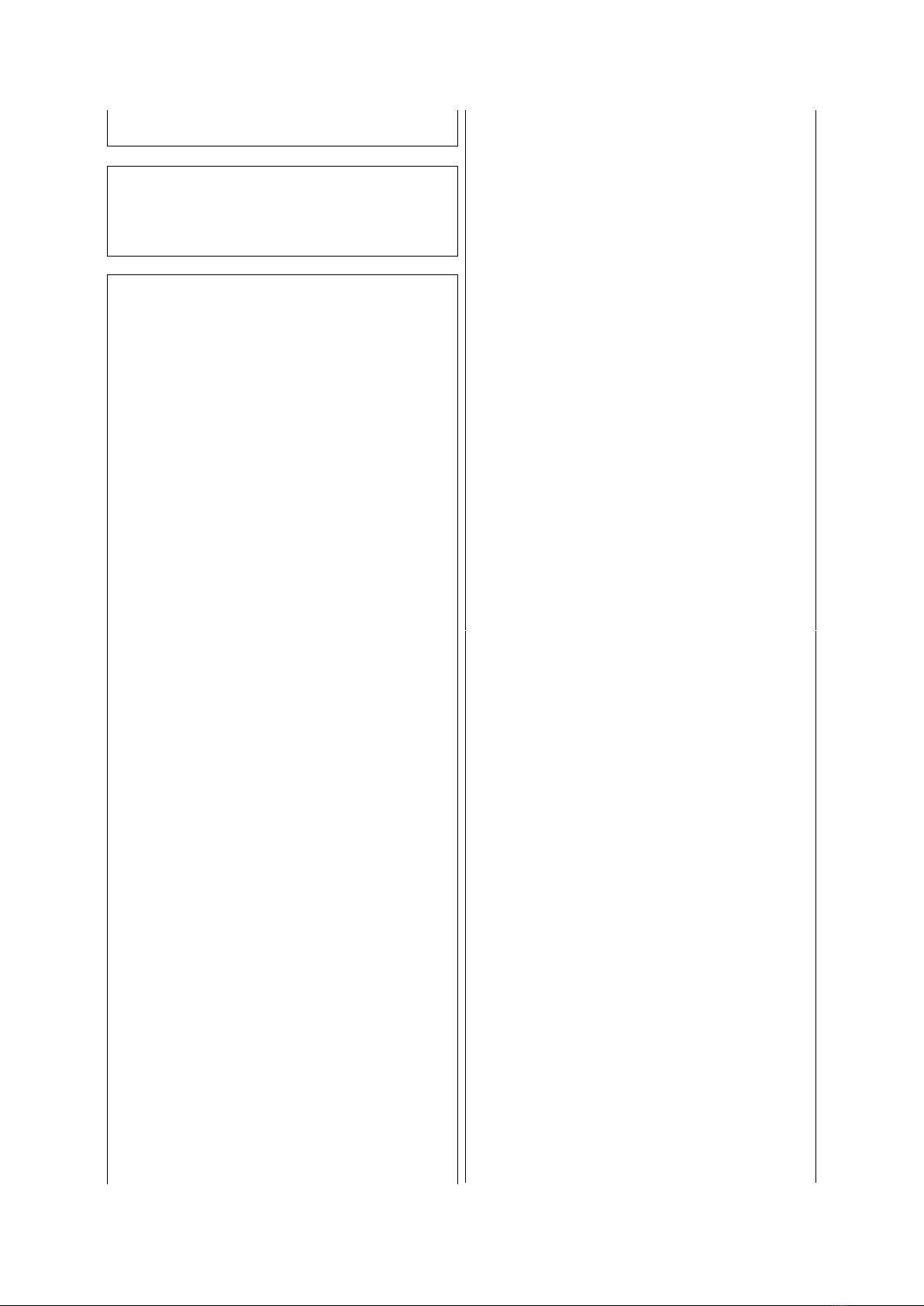

4

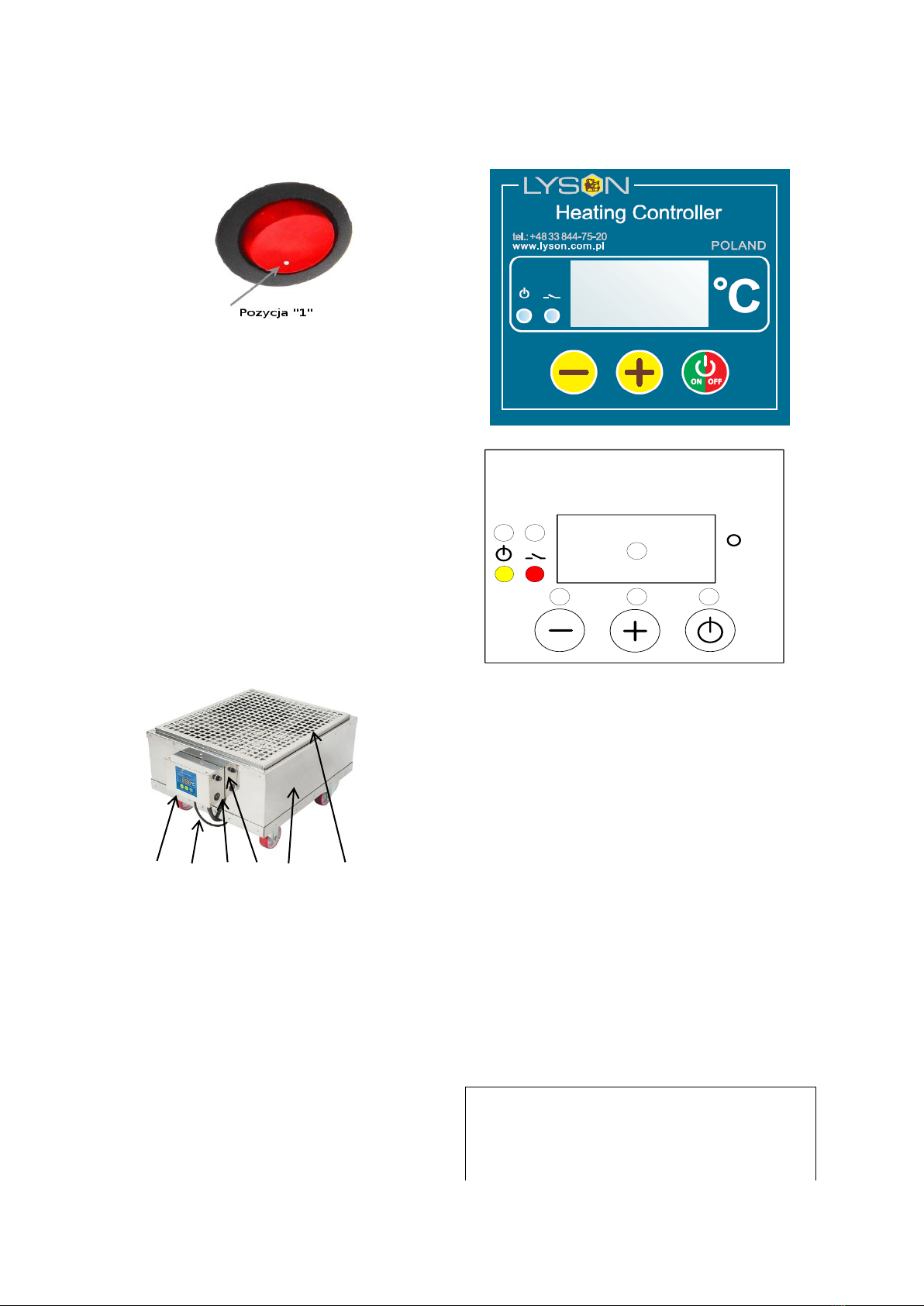

temperature regulator switched on and initial

heating in progress

2 –signalling the activation of heating

transmitter

Indicator lights up –transmitter contacts closed

(heating on), indicator dimmed –contacts opened

(heating off)

3 –display

Working mode –default mode, selected after

controller power supply switched on. The display

shows the measured temperature, readings

specified in oC.

Setting mode –selected when button “+” or “-

“ has been pressed. The display shows the preset

temperature. Readings specified in oC. Reading

flashes and returns to measured temperature

after a while.

Working time setting mode (Pro.) –activated

when “ON/OFF” button is pressed and held. The

display shows working time, counting it from

activation, after which the thermostat gets

switched off. Readings specified in hours.

Display brightness setting mode (d.br.) –

activated when “ON/OFF” button is pressed and

held for a longer time. The display shows the

currently set brightness on all its segments .

When the setting limit values are reached, the

segments start to flash.

The modes specified below are accessible

once the relevant code have been entered.

Calibration mode (CAL.) code L-1 –activated

when the “ON/OFF’ button has been pressed and

held for a longer time. The display shows the

measured temperature including the calibration.

Readings specified in oC.

Preliminary heating time setting mode (P.tI.)

code L-2 –activated when “ON/OFF” button is

pressed and held for a longer time. The display

shows the working time, counting it from the

activation, for which the controller performs

preliminary heating maintaining the preliminary

heating temperature programmed by the

manufacturer. Reading “OFF” means deactivation

of the preliminary heating function. Readings

specified in minutes. When preliminary heating

activated, the controller displays marking “HC2”

during start-up.

Preliminary heating temperature setting mode

(P.tE.) code L-3 –activated when the “ON/OFF”

button is pressed and held for a longer time. The

display shows the value of preset temperature for

preliminary heating. Readings P … specified in

oC.

Preset temperature limit setting mode (L.t.h.)

code L-4 –activated when “ON/OFF” button is

pressed and held for a loner time. The display

shows maximum value of preset temperature that

can be set . Readings L … are specified in oC.

4 –button „-„ value decreasing

Working mode –pressing the button will

decrease the preset temperature value. During

preliminary heating, the option to change the

setting for preset temperature is blocked.

Working time setting mode –pressing the

button will decrease the time after which the

thermostat will get switched off.

Display brightness setting mode –pressing the

button will decrease the brightness of the display.

Calibration mode –pressing the button will

decrease the value of the temperature to be

transferred, calibrating the measurement duct in

this way.

Preliminary heating time setting mode –

pressing the button will decrease the time after

which the thermostat will switch from preliminary

heating phase to proper heating phase.

Preliminary heating temperature setting mode

–pressing the button will decrease the value of

preset temperature that will be maintained during

preliminary heating.

Preset temperature limit setting mode –

pressing the button will decrease the value of

maximum preset temperature that will be to set.

5 –button „+” value increasing

Working mode –pressing the button will

increase the value of preset temperature. During

preliminary heating, the preset temperature

setting changes is blocked.

Working time setting mode –pressing the

button will increase the time after which the

thermostat gets switched off.

Display brightness setting mode –pressing the

button will increase the brightness of the display

Calibration mode –pressing the button will

increase the value of the transferred temperature,

calibrating the measuring duct in this way.

Preliminary heating time setting mode –

pressing the button will increase the time after

which thermostat switches from preliminary

heating phase to proper heating phase.

Preliminary heating temperature setting mode

pressing the button will increase the value of

preset temperature which will be maintained

during preliminary heating.

Preset temperature limit setting mode –

pressing the button will increase the value of

maximum preset temperature that can be set

6 –„ON/OFF” button

Short-time pressing of the button will activate

(ON) and deactivate (OFF) the regulator

interchangeably. At deactivated state (OFF) the

regulator act as a thermometer. At activated state

(ON) , the regulator shall activate and deactivate

the outlet to control the heater in order to maintain

the temperature set by the user.

Longer pressing and holding of the button and

subsequent button releasing will activate the