You need to leave your printer

unused for a period longer than four

weeks (two weeks in regions of high

temperature and/or low humidity), or

you want to remove the bulk ink feed

system from your printer for an

extended time.

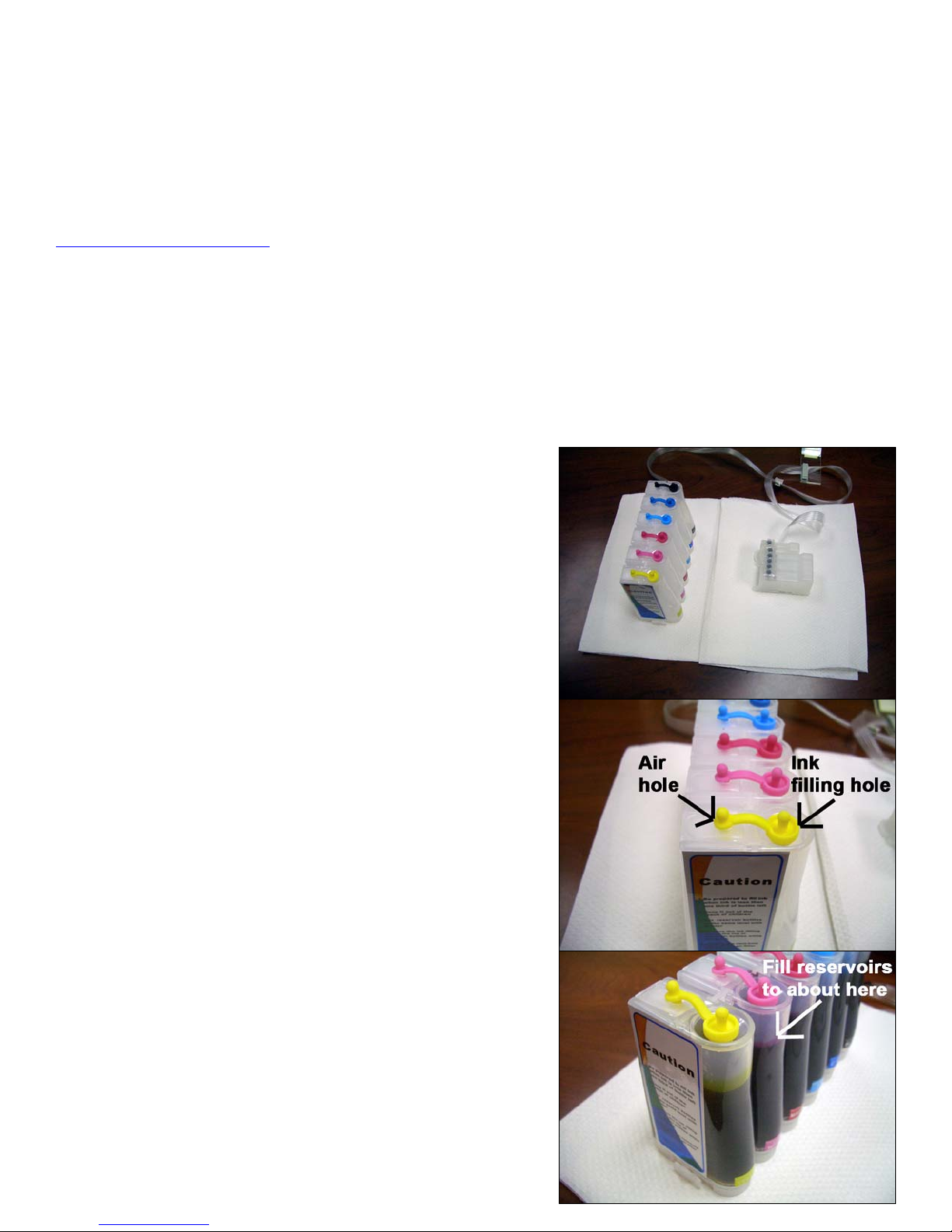

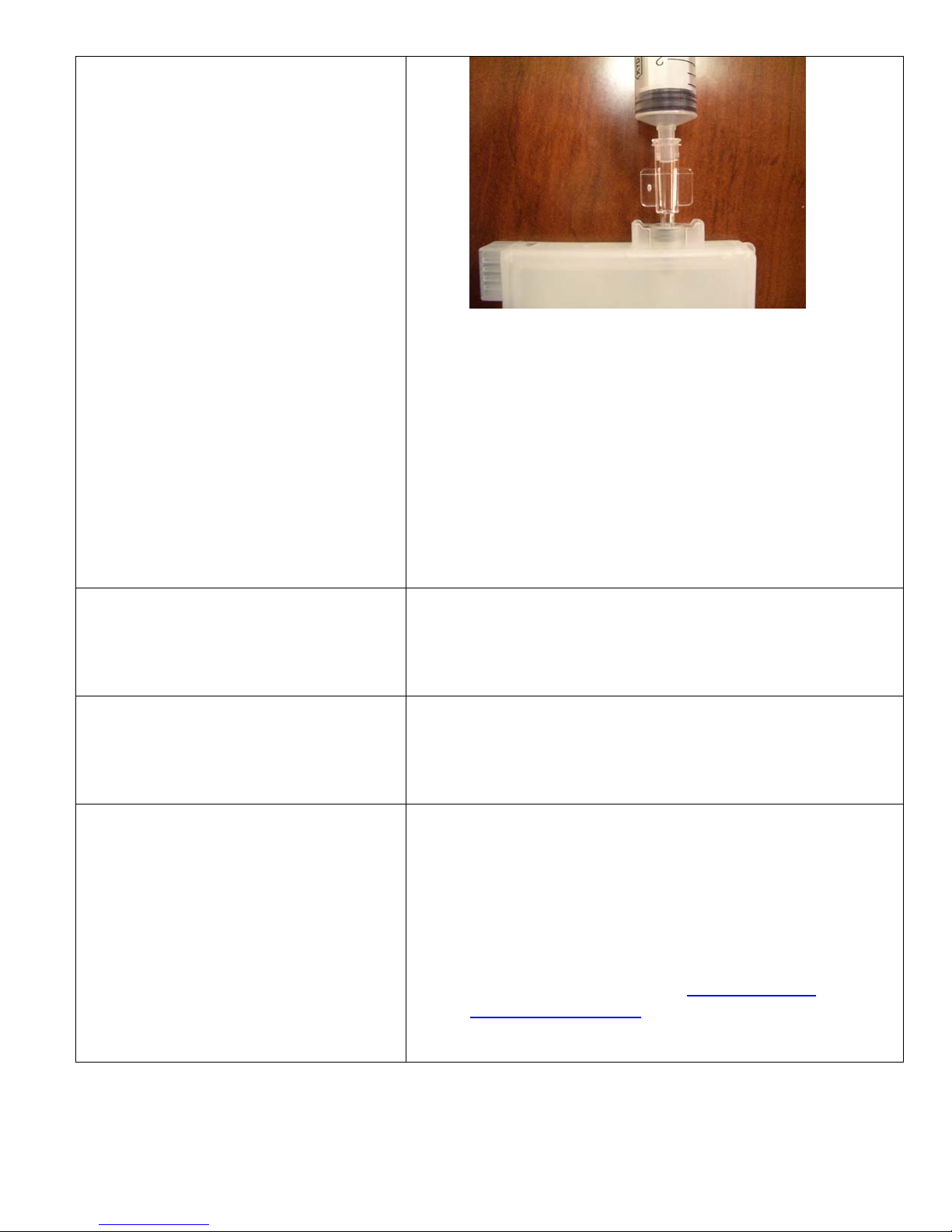

1. Remove all the air filters from the tops of the

reservoirs and insert the rubber bungs into the air

holes to seal the reservoirs.

2. Remove the cartridges from the printer and place

them in a plastic bag with the ink exit holes

upwards.

3. Open the tube clips by squeezing the small tab at

the front of each clip. The entire system can now

be removed from the printer for storage

4. Flush the printer with Lyson cleaning cartridges

available from your local Lyson supplier.

5. To re-install your system, follow the installation

guide from the beginning again except that the tube

support bracket and clips will already be attached

to your printer.

If you require technical assistance or support with your Lyson bulk ink feed system, please initially

contact the store or dealer where the system was purchased. All Lyson dealers are well trained in the

operation of the system and can help with most problems. Alternatively, contact Lyson technical

30 DAY GUARANTEE TO REPLACE DEFECTIVE PARTS

Lyson guarantee all parts are defect-free for a period of 30 days from the date that you receive your

new Lyson Bulk ink feed system. If you have received a defective part, please initially contact the

retailer or dealer from where the system was purchased.

DISCLAIMER

As Lyson bulk feeds are self installed by the user, Lyson is not responsible for any damages to your

printer, whether they are or are not related to the Lyson Bulk ink feed system. Please contact the

store or dealer where the printer was purchased, or the printer manufacturer for any problems or

questions related to the printer and its operation.

If the Customer chooses to use ink in the system from another manufacturer other than Lyson, and is

not satisfied with the ink, or it clogs the printer or the bulk feed system, it will be the Customers

responsibility to pay for the parts to repair the system and restore it to normal usage. We can only

guarantee that the Lyson Bulk ink system will deliver Lyson ink just as well as a normal ink cartridge.

We will not accept returns of used systems, or systems filled with third party ink that the customer

later decides does not meet their specific needs.