18.08.2014

Use and operation

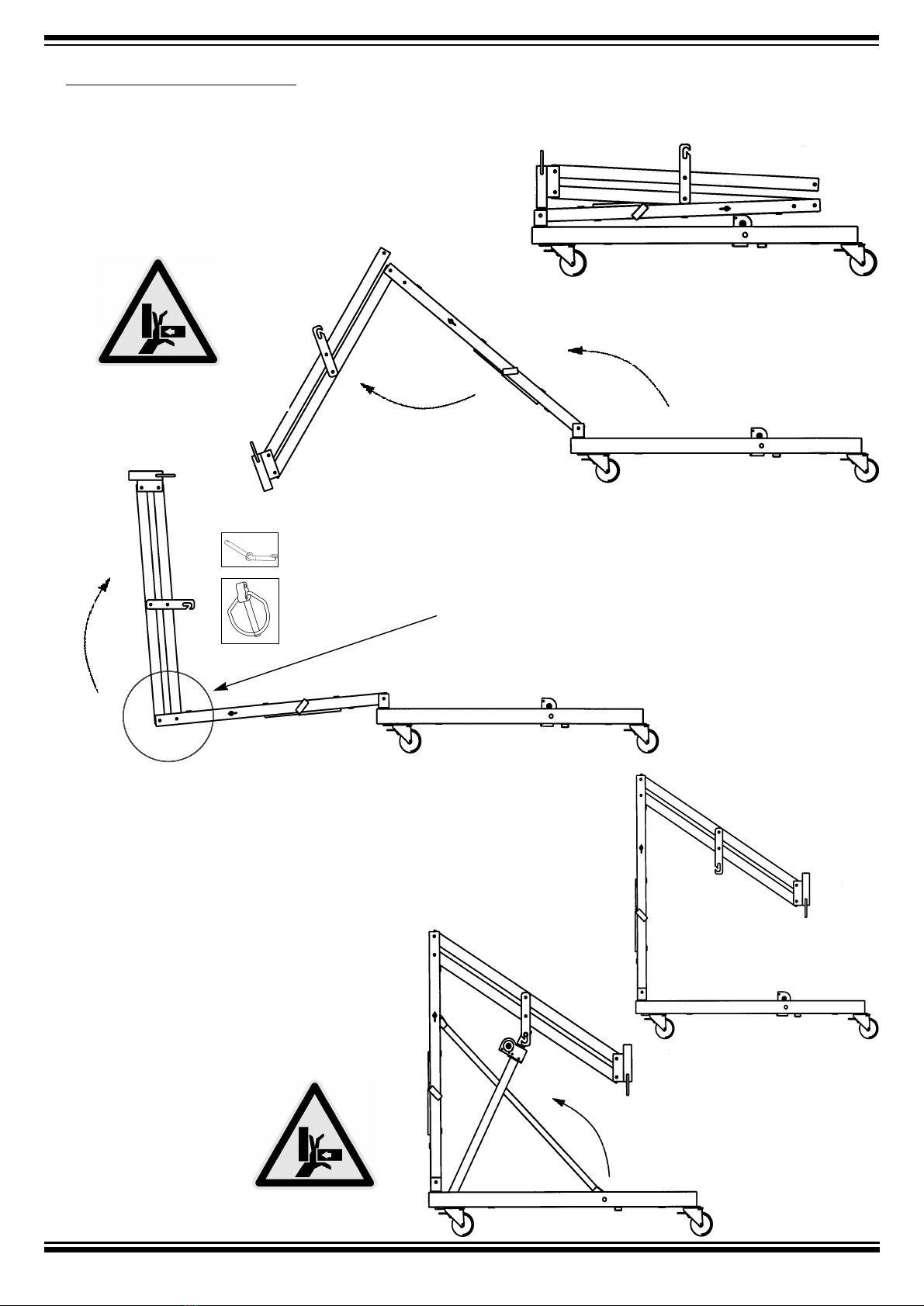

Important:

•The lifting jack may be set up only on horizontal-even,

capable of foundation.

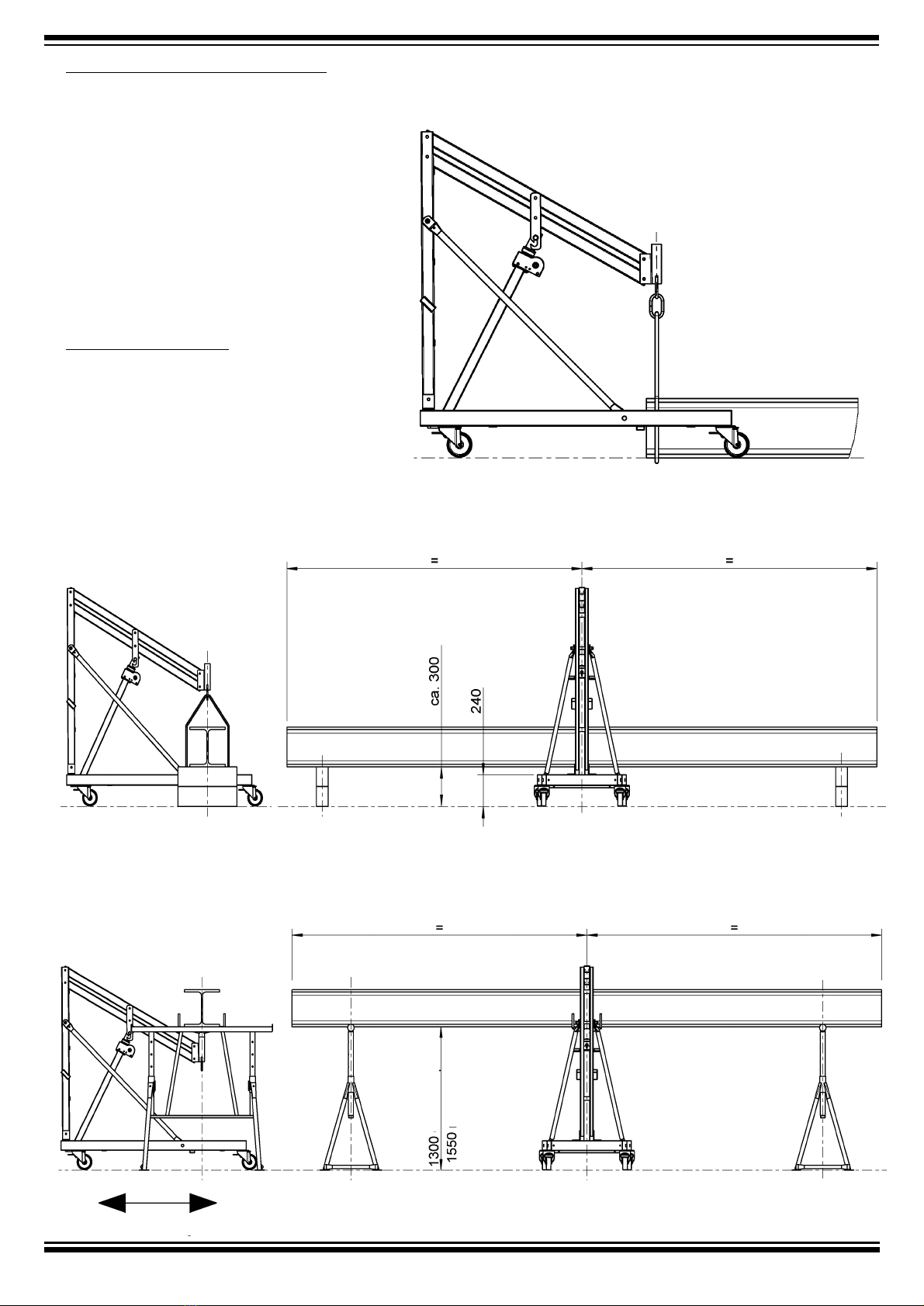

• The weight, e.g. a steel girder or a wood purlin, will be put

on the heading fork of the lifting jack or hooked into the

loop of the boom. The borings in the heading fork provide

the possibility of fixing the hung up load.

• The brakes of the swivel rollers must be fixed beforehand.

The swivel rollers should point to the outside once fixed,

to realise maximum contact width.

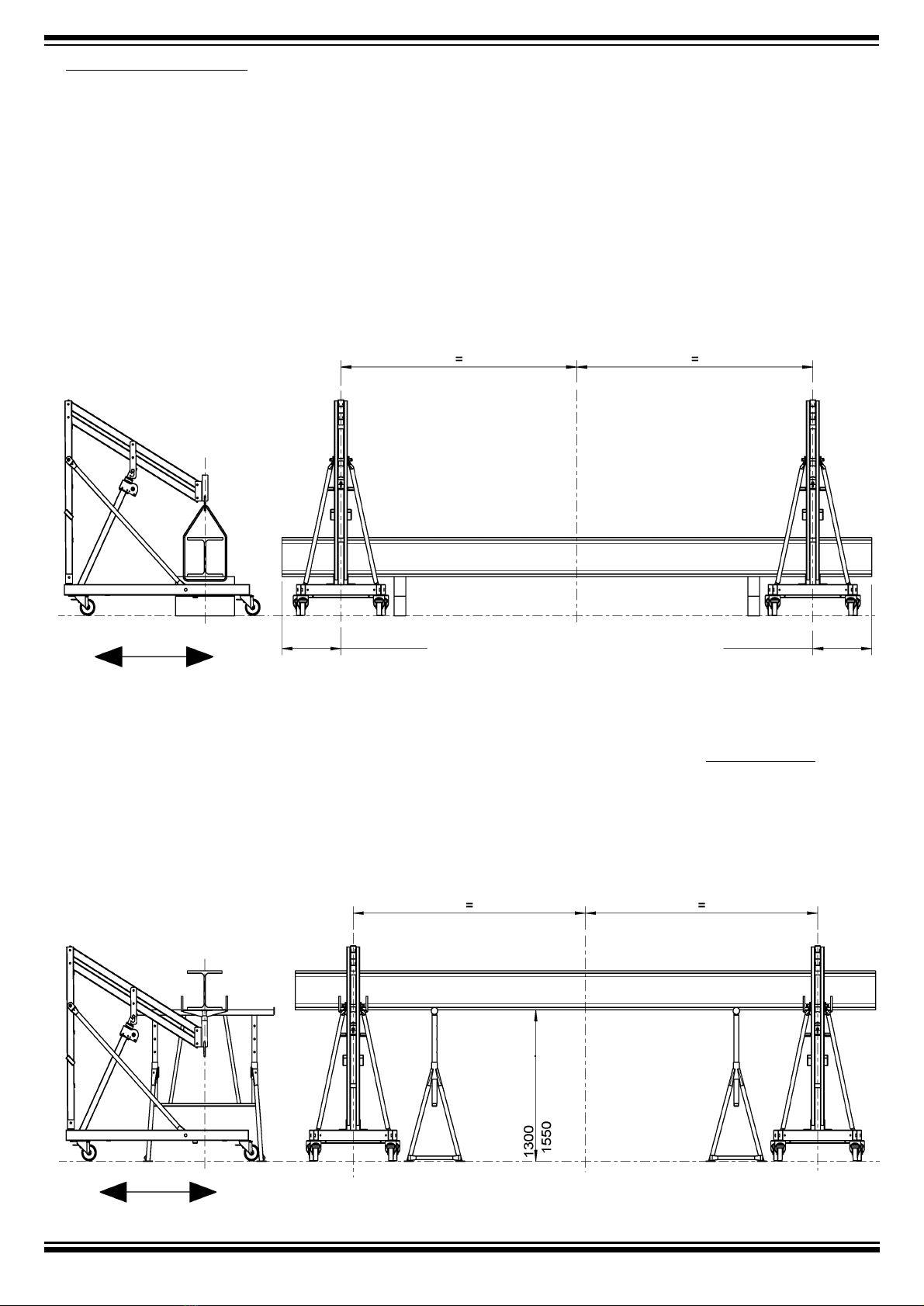

• If loads placed or suspended are to be moved, this must

be done in the deepest possible position of the boom.

When moving with lifted load there is a risk of turning

over!

• Moving with lifted load is only permissible in lifting jack

longitudinal direction! Risk of turning over!

• It is recommended to sweep off the surface on which the

lifting jack is moved under load. Even small stones hinder

the swivel rollers of the loaded device.

• Another recommendation is to additionally secure the

lifted load with scaffold jacks placed underneath during

movement.

The crank for infinite lifting and lowering of the load can

be attached on both sides of the spindle gear.

Its length is adjustable, so that a large radius (lever arm)

for lifting, or a small radius (faster) for unloaded

movement can be set.

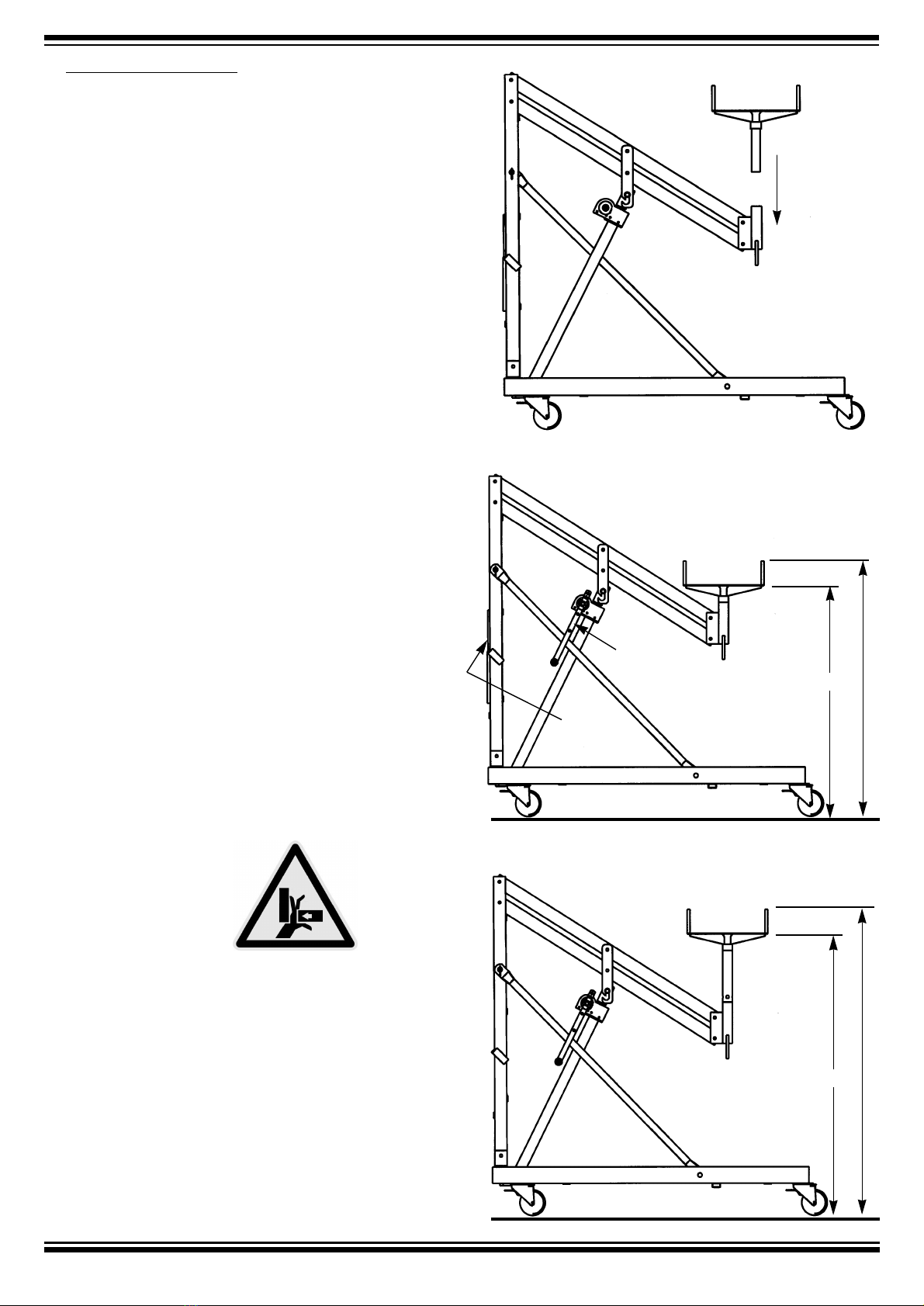

With the plug-on of the adapter, which is otherwise

between the two pipes of the stand, it is possible

to raise up the work height of the lifting jack

by 0.25 m to 3.00 m.

adapter

adapter

Caution, risk of crushing!

1.10 m

1.36 m

1.22 m

1.47 m

heading fork

load loop

crank