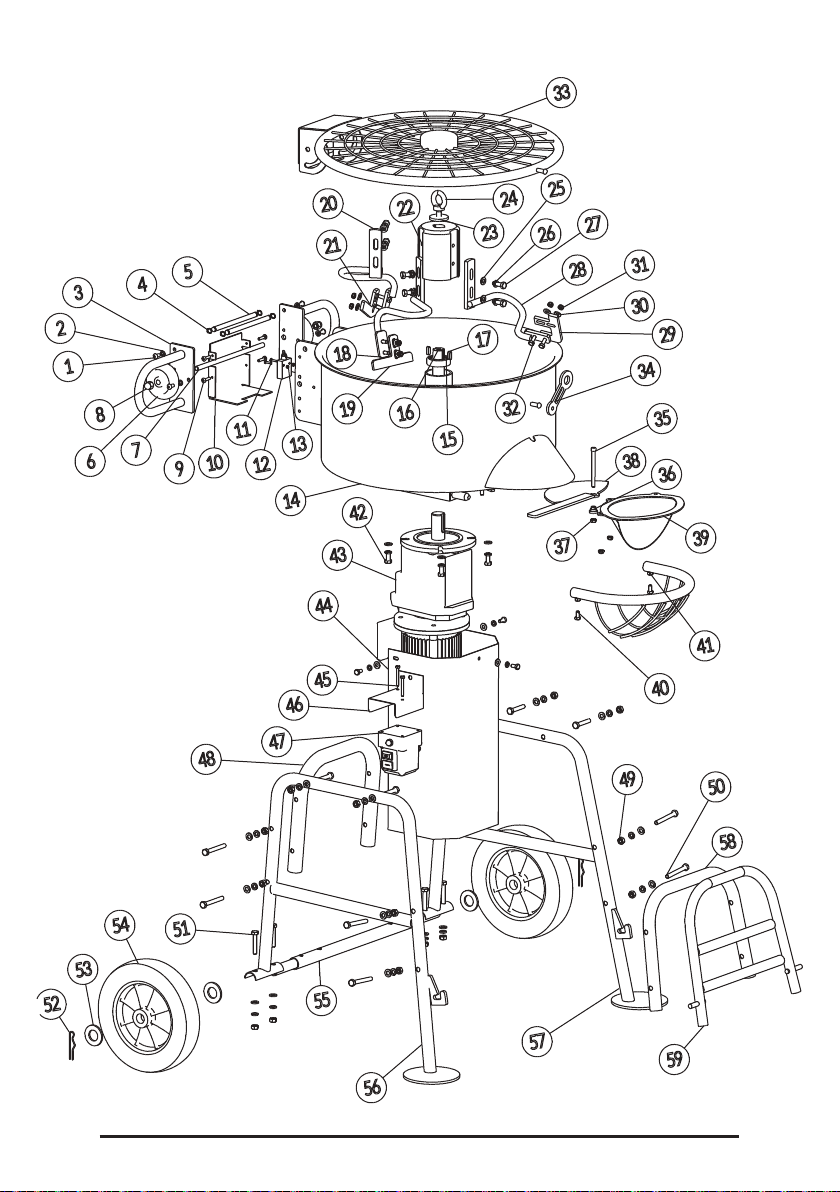

Pg 3

APPLICATION

The Mörser Forced Acon Mixers are ideal for mixing all kinds

of materials used in the building industry, as well as for tasks

where high demands are imposed on quality of the mix.

BEFORE USE

Before starng the mixer, the telescopic legs must be posioned

for the right height for draining into a bucket or wheelbarrow.

The easiest way for adjusng the legs is to lay down the mixer,

so it rests on all four wheels. The legs are released and locked

with the fied lock splits/bolts.

BEFORE CONNECTING THE POWER SUPPLY

Before the power is connected, the mixer arms must be set in

place, and the lid must be closed. The safety grid in front of the

mixer gate must be aached at all mes.

For own safety please always follow the instrucons listed

above before use.

OPERATING your MÖRSER MIXER

Close the lid and lock it into place using the rubber strap. Start

the mixer by pressing the start buon on the protecve

motor switch. Pour the required material into the drum and

add liquid.

The protecve motor switch has a zero voltage releaser. In case

of power failure, the mixer must be restarted. For safety

reasons, the mixer will not start if the lid is open.

NOTE

Never put your hand or any object into the machine when the

power is connected.

When the material has reached the desired consistency and

the mixing moon is finished, the mixing drum is emped by

opening the mixer gate. The drum should be emped shortly

aer mixing. Depending on the material being mixed, it may

set in the mixing drum if le too long.