KVS

P. 3 / 3 EM-3511 Rev.2

CHECKING

1) Terminal wiring: Check that all cables are correctly

connected according to the connection diagram.

2) Power input voltage: Check voltage across the terminal 7

–8 with a multimeter.

3) Input: Check that the input signal is within 0 –100% of

the full-scale.

4) Output: Check that the load resistance meets the de-

scribed specifications.

ADJUSTMENT PROCEDURE

This unit is calibrated at the factory to meet the ordered

specifications, therefore you usually do not need any calibra-

tion.

For matching the signal to a receiving instrument or in case

of regular calibration, adjust the output as explained in the

following.

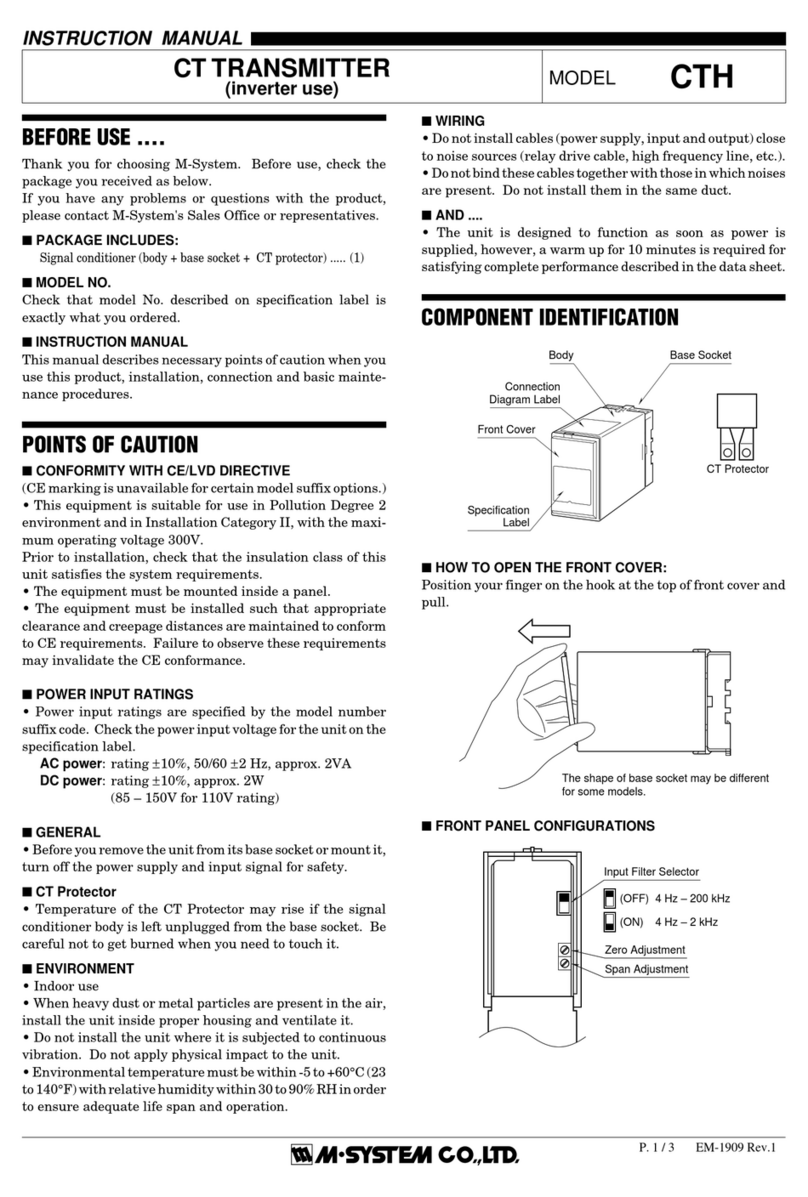

■ HOW TO CALIBRATE THE OUTPUT SIGNAL

Use a signal source and measuring instruments of sufficient

accuracy level. Turn the power supply on and warm up for

more than 10 minutes.

1) ZERO: Apply 0% input and adjust output to 0%.

2) SPAN: Apply 100% input and adjust output to 100%.

3) Check ZERO adjustment again with 0% input.

4) When ZERO value is changed, repeat the above procedure

1) –3).

POINTS OF CAUTION

■ GENERAL

•Before you remove the unit from its base socket or mount it,

turn off the power supply and input signal for safety.

■ ENVIRONMENT

•When heavy dust or metal particles are present in the air,

install the unit inside proper housing and ventilate it.

•Do not install the unit where it is subjected to continuous

vibration. Do not apply physical impact to the unit.

•Environmental temperature must be within -5 to +55°C (23

to131°F)withrelativehumiditywithin30to90%RHinorder

to ensure adequate life span and operation.

■ WIRING

•Do not install cables (power supply, input and output) close

to noise sources (relay drive cable, high frequency line, etc.).

•Donot bind these cables together with thosein which noises

are present. Do not install them in the same duct.

■ AND ....

•The unit is designed to function as soon as power is

supplied, however, a warm up for 10 minutes is required for

satisfying complete performance described in the data sheet.

MAINTENANCE

Regular calibration procedure is explained below:

■ CALIBRATION

Warm up the unit for at least 10 minutes. Apply 0%, 25%,

50%, 75% and 100% input signal. Check that the output

signal for the respective input signal remains within accu-

racy described in the data sheet. When the output is out of

tolerance, recalibrate the unit according to the "ADJUST-

MENT PROCEDURE" explained earlier.

M-SYSTEM WARRANTY

M-System warrants such new M-System product which it manufactures to be free from defects in materials and workmanship during the 36-month period following the date that such

productwasoriginallypurchasedifsuchproducthasbeenusedundernormaloperatingconditionsandproperlymaintained,M-System'ssoleliability,andpurchaser'sexclusiveremedies,

under this warranty are, at M-System's option, the repair, replacement or refund of the purchase price of any M-System product which is defective under the terms of this warranty. To

submit a claim under this warranty, the purchaser must return, at its expense, the defective M-System product to the below address together with a copy of its original sales invoice.

THIS IS THE ONLY WARRANTY APPLICABLE TO M-SYSTEM PRODUCT AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. M-SYSTEM SHALL HAVE NO LIABILITY FOR CONSEQUENTIAL, INCIDENTAL OR

SPECIAL DAMAGES OF ANY KIND WHATSOEVER.

M-System

Co.,

Ltd.,

5-2-55,

Minamitsumori,

Nishinari-ku,

Osaka

557-0063

JAPAN,

Phone:

(06)

6659-8201,

Fax:

(06)

6659-8510,

E-mail:

[email protected]