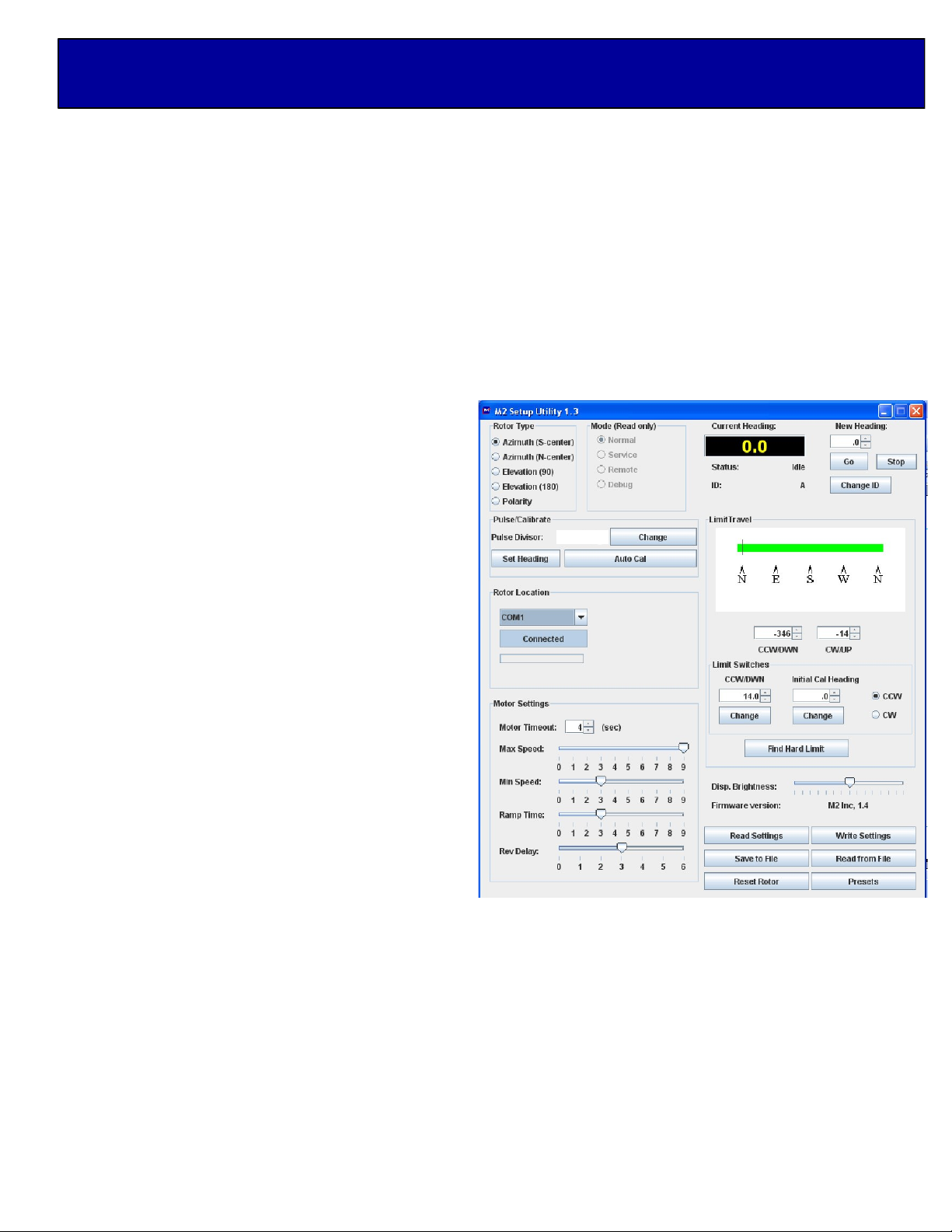

New Heading: Change or type the desired heading

value and click on “Go.” The “Stop” command will

immediately stop the current motion.

Change ID: Changes the ID Byte as stored in the

controller. This can be used to identify a specific

controller board and controller based upon your

usage.

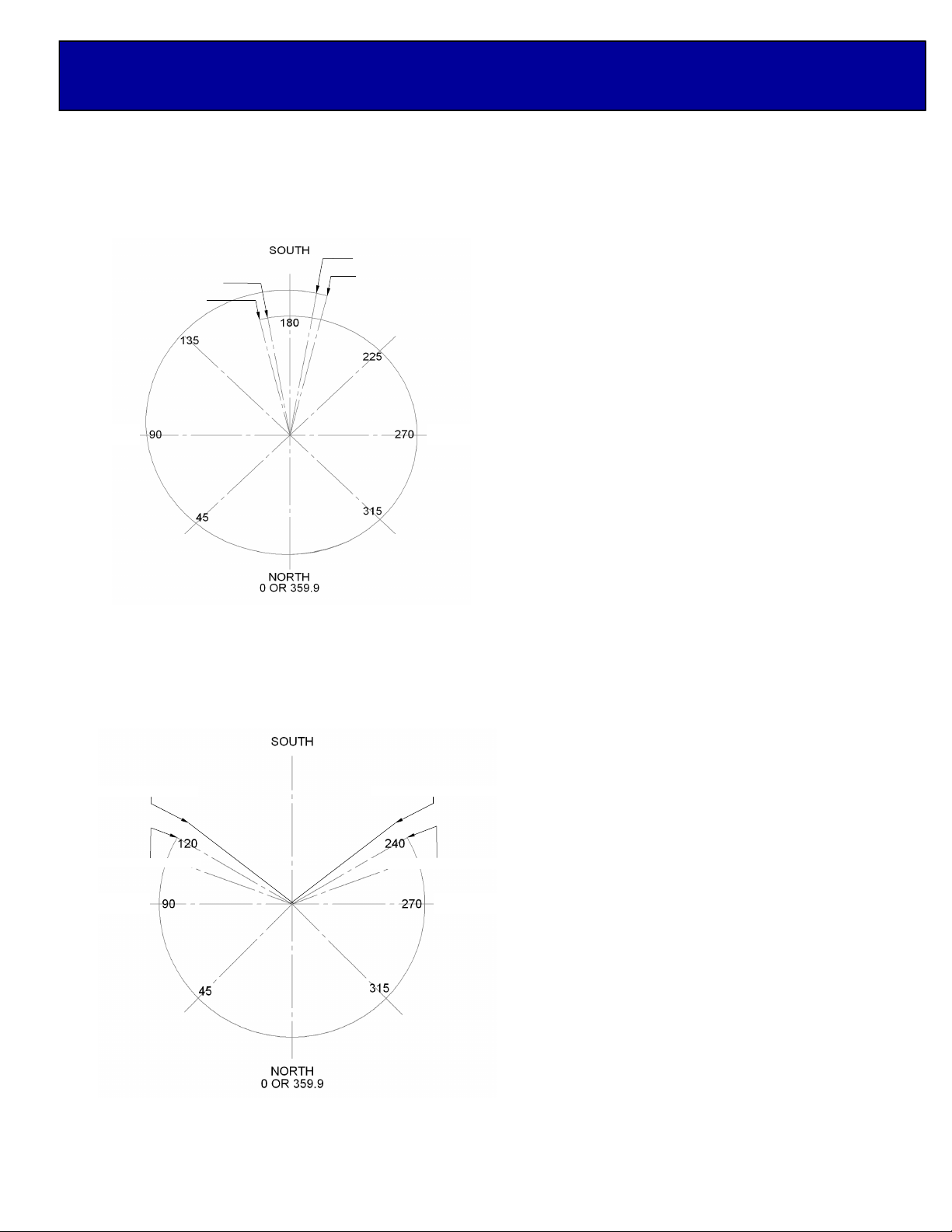

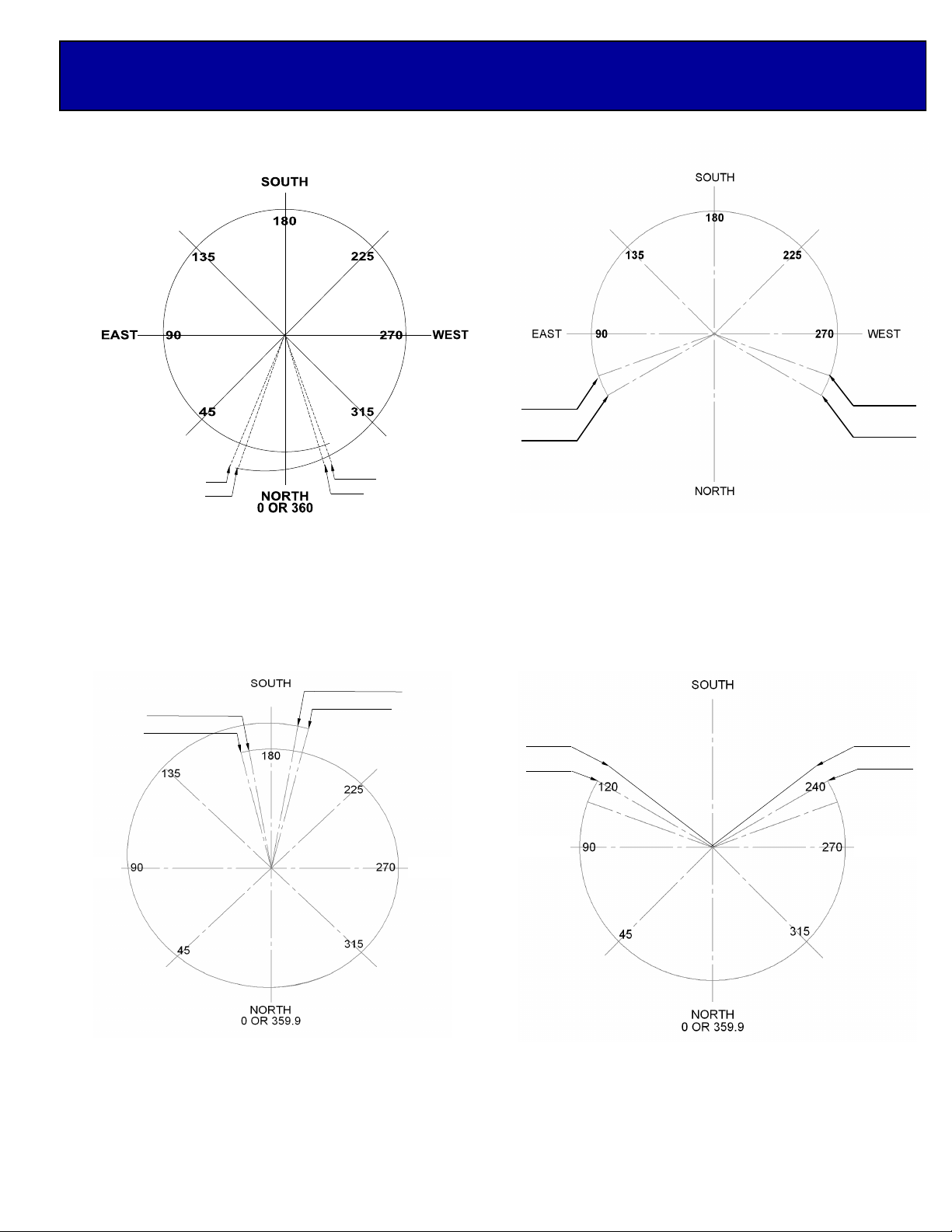

Limit Travel: A graphical representation of allowable

range of the motion as defined by the current po-

sitioner type and the Soft Limits set in the Limit Travel

spinners located just below the graphic.

Limit Switches: CCW / DWN or CW / UP defines

the number of degrees and tenths that the

CCW / DWN or CW / UP limit switch is physically

located from the known start heading.

Initial Cal Heading: This defines the known starting

location in degrees. Normally a fixed location within

your standard travel pattern.

Find Hard Limit: Once the determined hard limit is

chosen, whether it be CCW / DWN or CW / UP,

pressing the Find Hard Limit will run the positioner at

the slowest speed until it trips the limit switch.

The measured CCW / DWN or CW / UP limit switch

value will then be saved in the controller for use by

the Auto Cal Function.

Display Brightness: Changes the brightness level of the LED Display.

Firmware Version: Displays the current firmware from the controller when connected.

Read Settings: Button that will read the settings from the controller and re-populate the SETUP window.

Write Settings: Writes any changes made to values in the SETUP Utility window that do NOT have their own

“Change Button.” All values are re-read after a Write Settings.

Save to File: Saves the current settings into a file for later recall and writing to a controller. This is a backup

mechanism so that you may save each controller’s settings into separately named files and recall them for later

use should the controller need to be replaced, or otherwise restored.

Read from File: Reads the saved values from the specified file. Use Write Settings after a read in order to

restore the values back into a controller.

Reset from File: Reads the saved values from the specified file. Use Write Settings after a read in order to

restore the values back into a controller.

Presets: Reads the (10) current presets from the controller and displays them for change. You may change only

one preset at a time with the Preset Window.

13200

M2 SETUP UTILITY OVERVIEW CONTINUED...