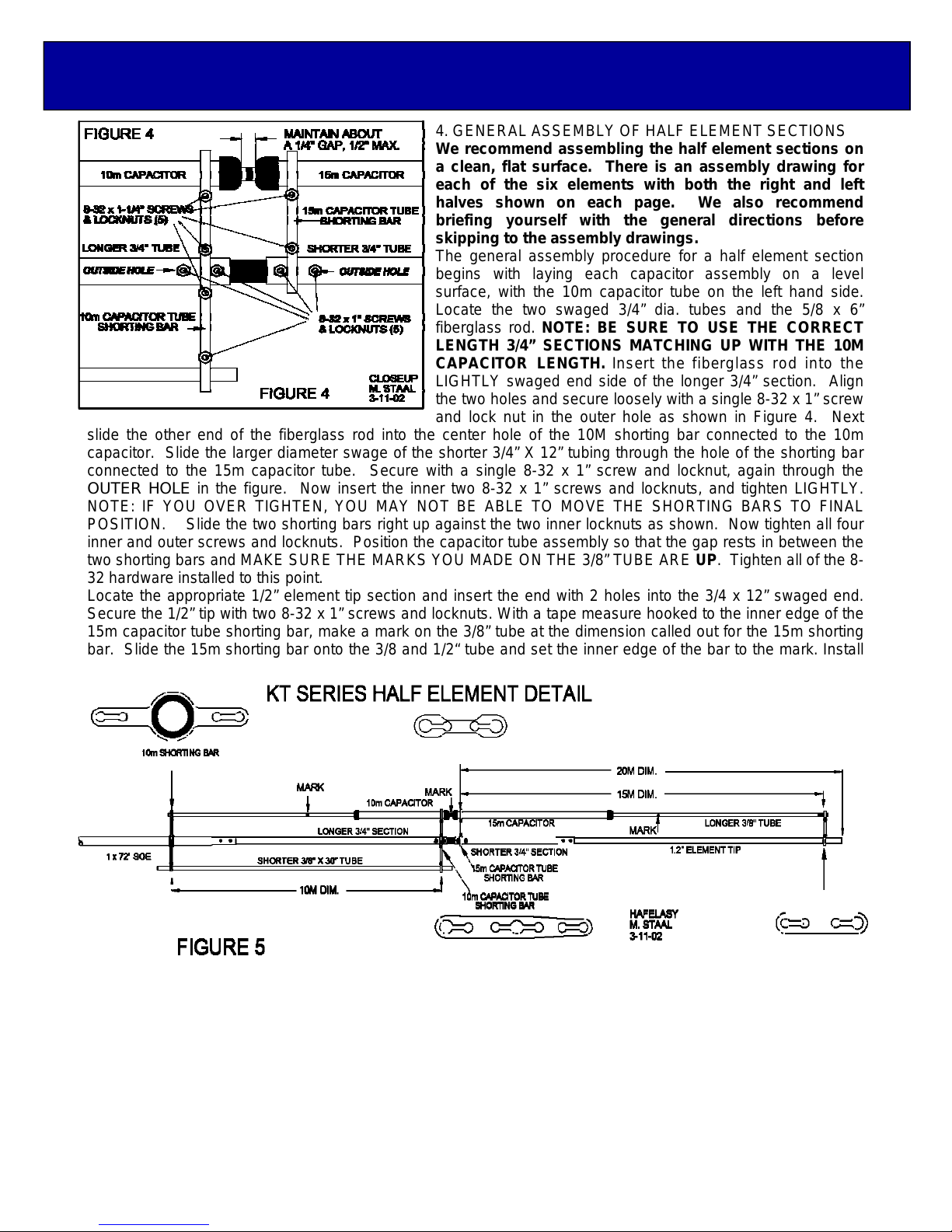

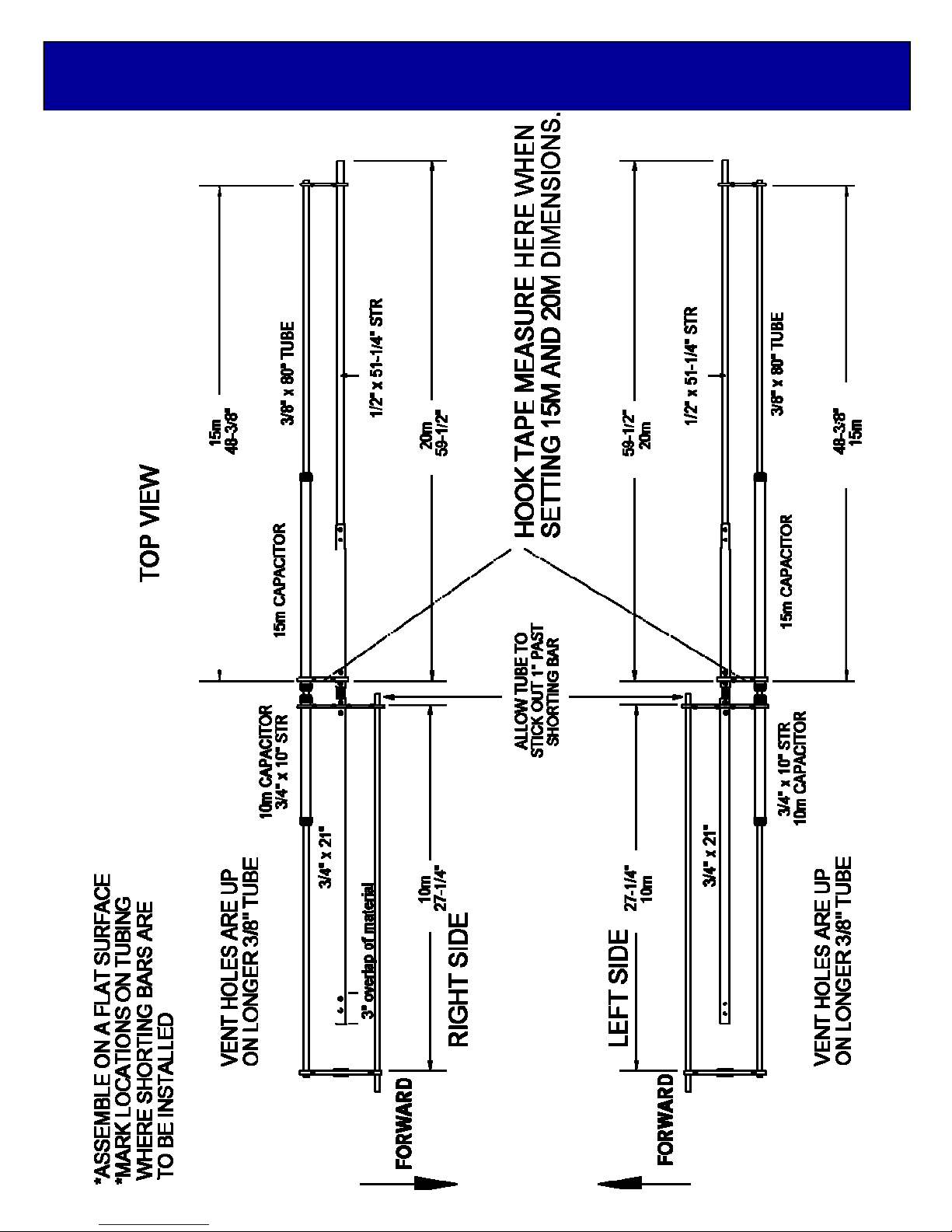

10. ELEMENT INSTALLATION

We advise that you elevate the antenna boom onto a couple of sawhorses or bucks for the remaining assembly

steps. Use the DIMENSION SHEET as a guide to properly install the six elements onto the boom. If you have

not labeled which side of the element faces towards the front of the antenna, you will want to pay close attention

to the DIMENSION SHEET. In fact, you might want to label them now. You also might want to have a friend

handy to keep the antenna from moving on you.

Place the REFLECTOR ELEMENT onto the boom in the orientation shown on the DIMENSION SHEET. Set the

outside edge of the element clamp plate 2-1/2” from the rear of the boom. Locate two 3” saddles and insert

two

1/4-20 x 3” bolts through each of the holes. Next attach the two saddles to the underside of the element clamp

plates, and lightly tighten the entire assembly, so the element won’t move. Using a tape measure hooked to the

outside edge of the clamp plate facing the rear, mark off the location for the outside edge of the element clamp

on the REAR DRIVEN ELEMENT assembly with a marking pen or pencil. Install the REAR DRIVEN ELEMENT

as you did for the REFLECTOR. BE CAREFUL! This element is not installed in the same orientation. Make

sure you follow the element placement on the DIMENSION SHEET. Continue installing the rest of the elements

in the same fashion. Since the 2nd director only has one element clamp plate, it requires just a single 3” saddle.

Also take note that this element can be placed on the boom with the clamp cap facing either the FRONT or

REAR of the antenna.

After all of the elements have been installed take a couple of steps back and look down from the end of the

antenna. Check to see if the elements are lined up with one another. If any need to be fixed, simply loosen the

saddles, straighten, and re-tighten.

11. INSTALLATION OF PHASING LINES

Locate the two 3/8” tube phasing lines, the phasing line insulator, and one cable tie. Insert both tubes into the

two holes on the insulator. Temporarily loosen the 1/4-20 locknuts located on the FRONT and REAR DRIVEN

ELEMENTS and slide the two phasing lines into the one of the 3/8” clamp block sets. Allow the ends of the

phasing lines to stick out 4” past the ends of the clamp blocks. Now pull the phasing lines back, guiding them

into the clamp block set on the other driven element. Now re-tighten the four 1/4-20 locknuts. Set the insulator

about midway between the two elements and secure it with large nylon tie inserted through the bottom hole and

around the boom.

12. BALUN INSTALLATION

Refer to the figures on DUAL DRIVEN AND T-MATCH ASSEMBLY for this procedure.

Loosen the 2-1/2” U-bolt on the L-bracket and insert the 4:1 HF Balun with the connector facing towards the front

of the antenna. Position the Balun so that the U-bolt hits the edge of the front cap. Now tighten the U-bolt just

enough to hold firmly in place. BE CAREFUL! Overtightening might crack the case of the Balun. On each of the

mounting posts on the balun attach the balun straps (shorter side).

13. ‘T’-MATCH INSTALLATION

Refer to the figures on DUAL DRIVEN AND T-MATCH ASSEMBLY for this procedure.

Locate the two 1/2 x 23-1/2” ‘T’-Feed tubes and 3/8 x 10” fiberglass insulator. Install the 3/8” fiberglass insulator

into one of the 1/2” ‘T’-feed tubes. Align the holes and temporarily secure with a 8-32 x 1” screw. Now feed the

undrilled ends of both ‘T’-feed tubes into the two ‘T’-match shorting bars. Slide one of them back so you can

install the other end of the 3/8” fiberglass rod into the other 1/2” tube. Align the holes and secure with another 8-

32 x 1” screw. With all of the hardware loose, rotate the entire ‘T’-Match assembly up so that the two 8-32

screws fit right into the two Balun straps. Secure the two 8-32 screws with two 8-32 locknuts. Make sure there

is ample room to connect your feedline to the balun. Now set the two shorting bars to the dimensions shown on

the DIMENSION SHEET and tighten all the hardware.

14. BOOM TO MAST PLATE INSTALLATION

Locate the boom to mast plate, 3” U-bolts & saddles, and 2” U-bolts & saddles. Install the four 2” U-bolts on one

side of the boom to mast plate. Center the plate at the location shown on the DIMENSION SHEET, and install it

using the 3” U-bolts, saddles, 3/8” nuts, and lockwashers. If possible, attach the feedline to the balun and route

it forward to about 18 feet from the rear of the boom. Seal the connector with black tape, coax seal or

equivalent. A 3” U-bolt pattern exists should you need to mount the antenna to a 3” mast.

KT36XA ASSEMBLY MANUAL