September 16, 2020 Page 9 of 12

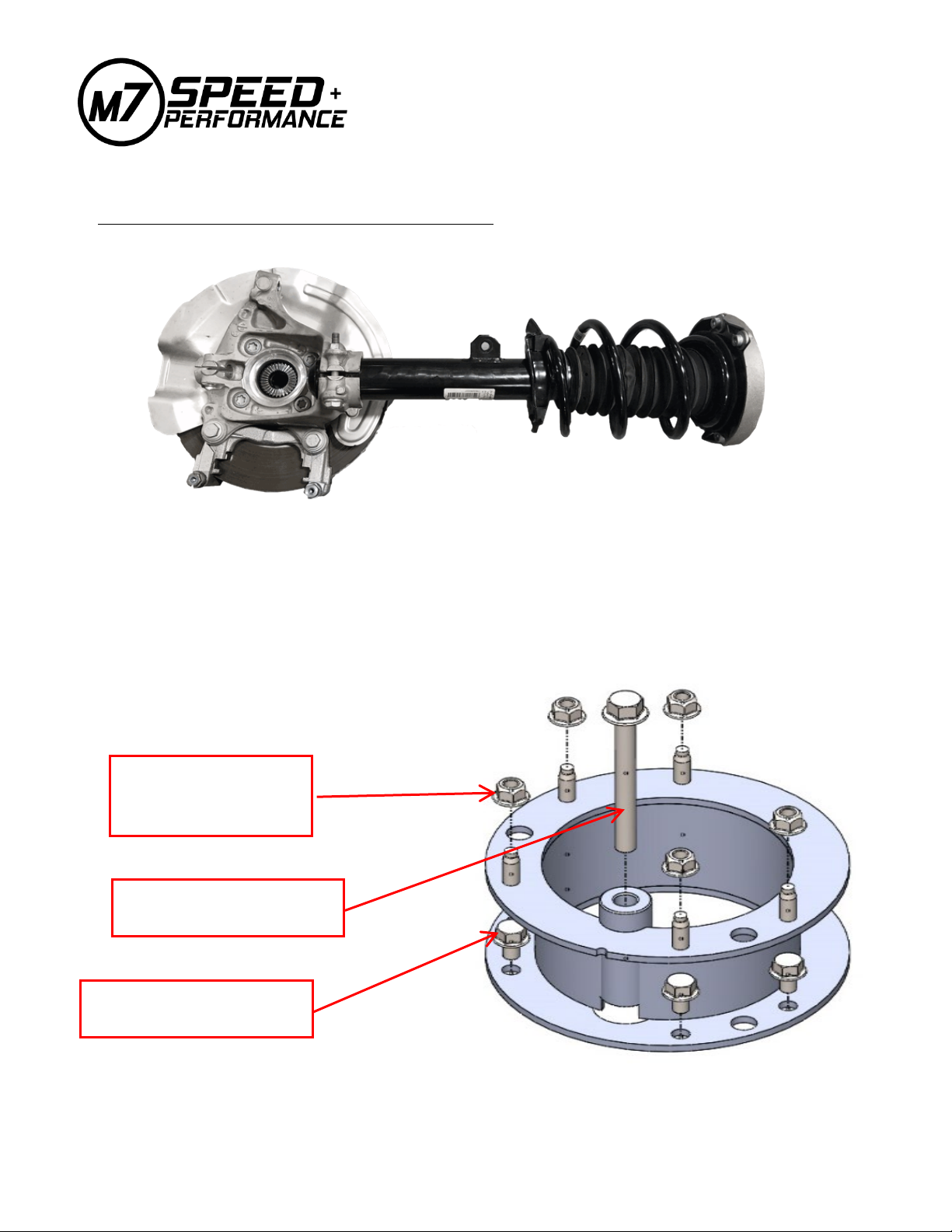

RE-ASSEMBLY-FRONT SUSPENSION

1. Slide the swing arm center pivot bushing and swing arm out from its location in the front sub-frame allowing the

swing arm to drop down. A pry bar may be needed.

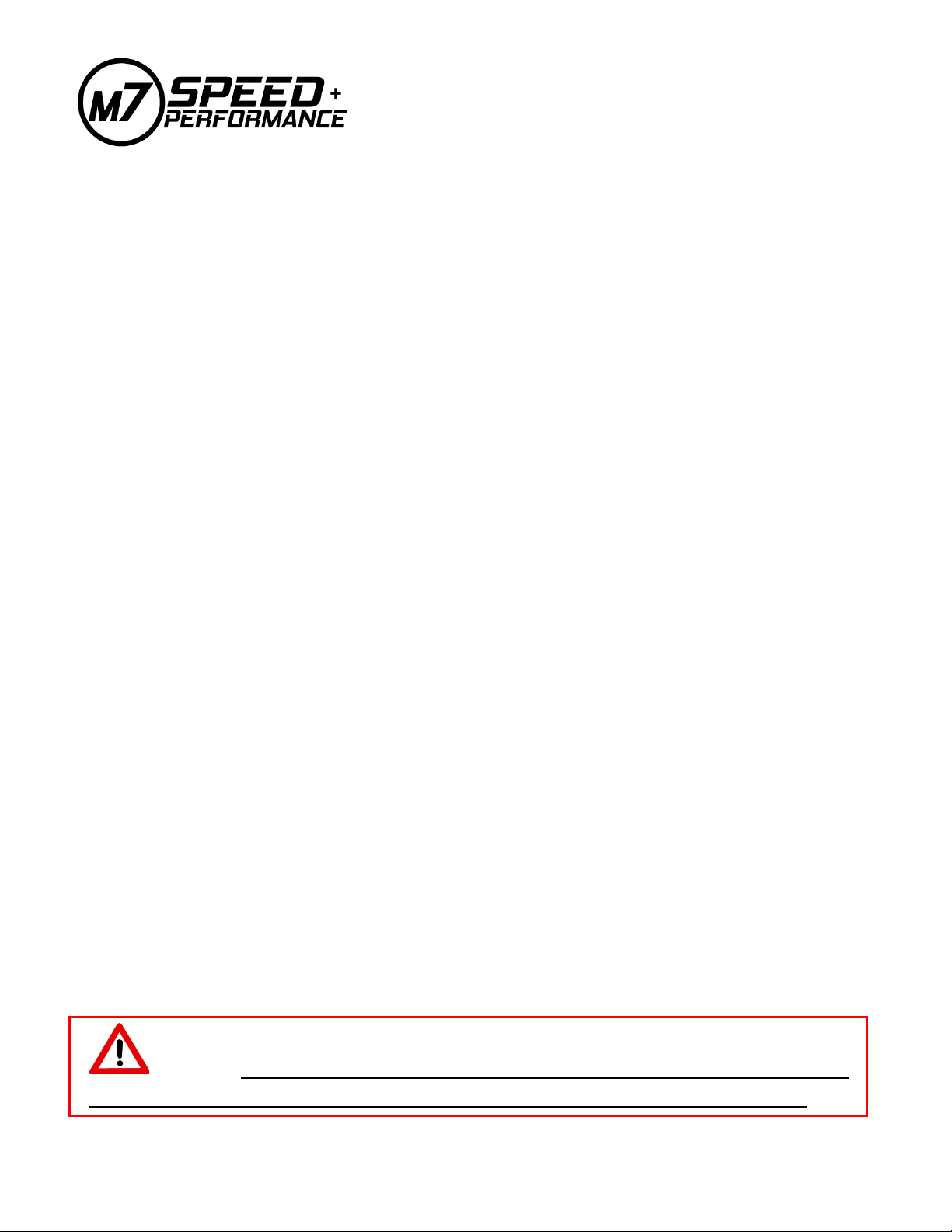

2. Install the strut assembly with the installed riser block into its location on the vehicle. Index the top using the M8

studs on the riser block to help with alignment.

3. Install the five M8 flanged lock nuts. Hand tighten only.

4. With the strut assembly hanging in the car and the lower swing arm free from the center pivot location insert

the steering tie rod pin and ball joint pin into the upright. Loosely install the OE fasteners. At the same time you

are doing this, pre-align the outer CV joint to the drive face and centerline of the hub.

5. Once the lower ball joint and steering tie rod pin are in place and secured, final align the outer CV joint with the

hub. Start threading in the CV drive bolt into the CV joint. Rotate the CV joint as you thread in the bolt to ensure

the drive teeth on the CV joint are aligned with the drive teeth on the hub. Snug up the bolt to remove all free

play.

6. Reposition and slide the lower swing arm pivot back into its OE mounting bracket. If it will not go back into

place easily chances are the drive axle slipped out of the inner CV joint. Slide the axle back into the inner CV

joint and finish aligning the pivot hole with the bolt hole. Excessive force should not be required. If it still will

not reassemble easily something is out of place or not assembled correctly. Double check all components to

verify correct assembly and alignment.

7. Once correctly aligned install the pivot bolt. Torque the OE pivot bolt to 75 lb-ft [100Nm] + 90 degrees rotation

(torque to yield)

8. Torque the outer steering tie rod end to 75 lb-ft [100Nm]

9. Torque the lower Ball Joint cross bolt to 45 lb-ft (60Nm)

10. Torque the CV drive bolt to 155 lb-ft [210 Nm] + 90 degrees rotation (torque to yield)

11. Reinstall the brake caliper, brake line bracket, headlight sensor bracket and wheel speed sensor. Verify

everything is tight and correctly torqued to OE specifications.

12. Install the MAXX-G Front sway bar links.

a. Set both links to the same length and lock the jam nuts.

b. Install one end into the front sway bar hole and the other end into the strut mounting bracket.

c. Place one thick washer on each stud.

d. Install the M10 castle nut. Torque to 30 lb-ft [40Nm]

e. Install the cotter pin.

13. Torque the five strut tower top nuts to 22 lb-ft [30Nm]. “DO NOT USE AN IMPACT GUN!”

14. Place the OE plastic strut top cover (if equipped) into its location sliding it over the chassis tie-bar.

15. Install the M7 supplied M10-1.25 x 80mm long Flange Head bolt through the chassis tie-bar and the M7 riser

block. Thread it into the OE strut plate. Torque to 40 lb-ft [55 Nm].

16. Repeat the complete front procedure for the other side of the vehicle.

NOTE: When both sides of the front suspension is completed safety check all

components for proper and complete installation and correct hardware tightness.