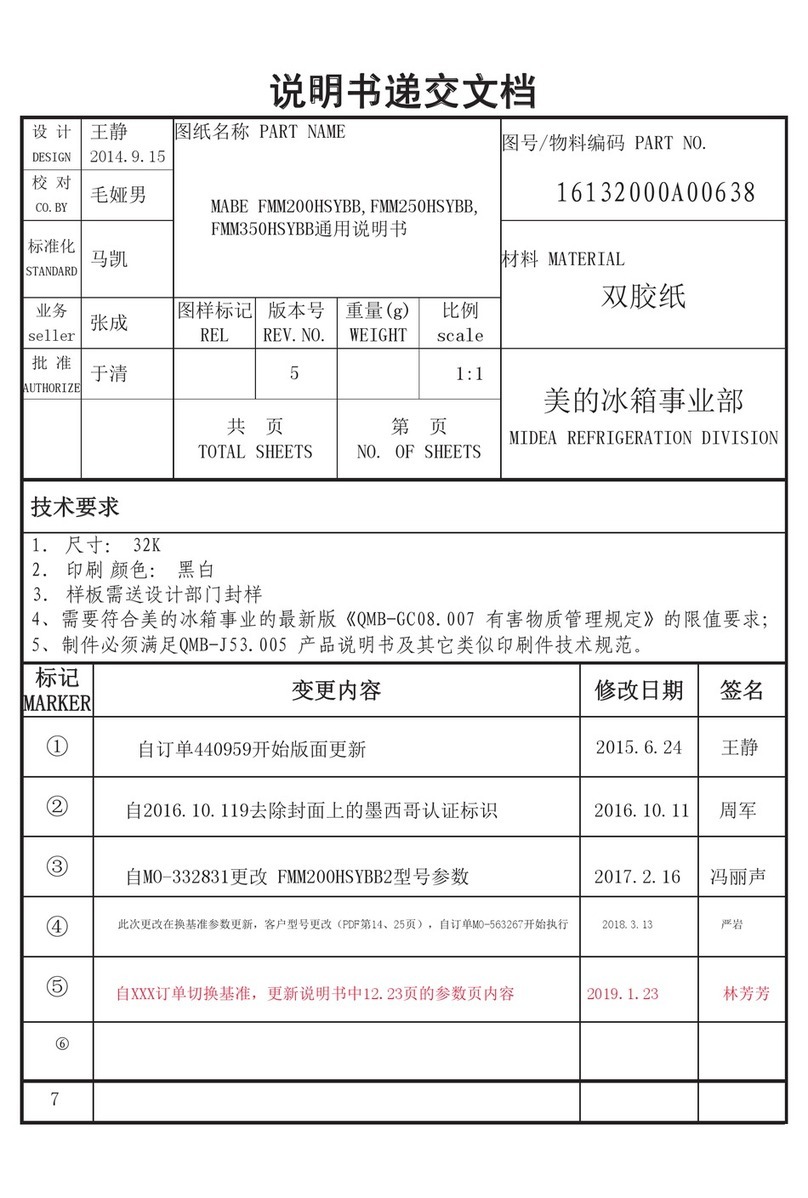

Contents

Chapter 1 General Information .................................................................................................................. 3

1-1. General Guidelines............................................................................................................................. 3

1-2. Insurance Test .................................................................................................................................... 3

1-3. How to read this Service Manual ........................................................................................................ 4

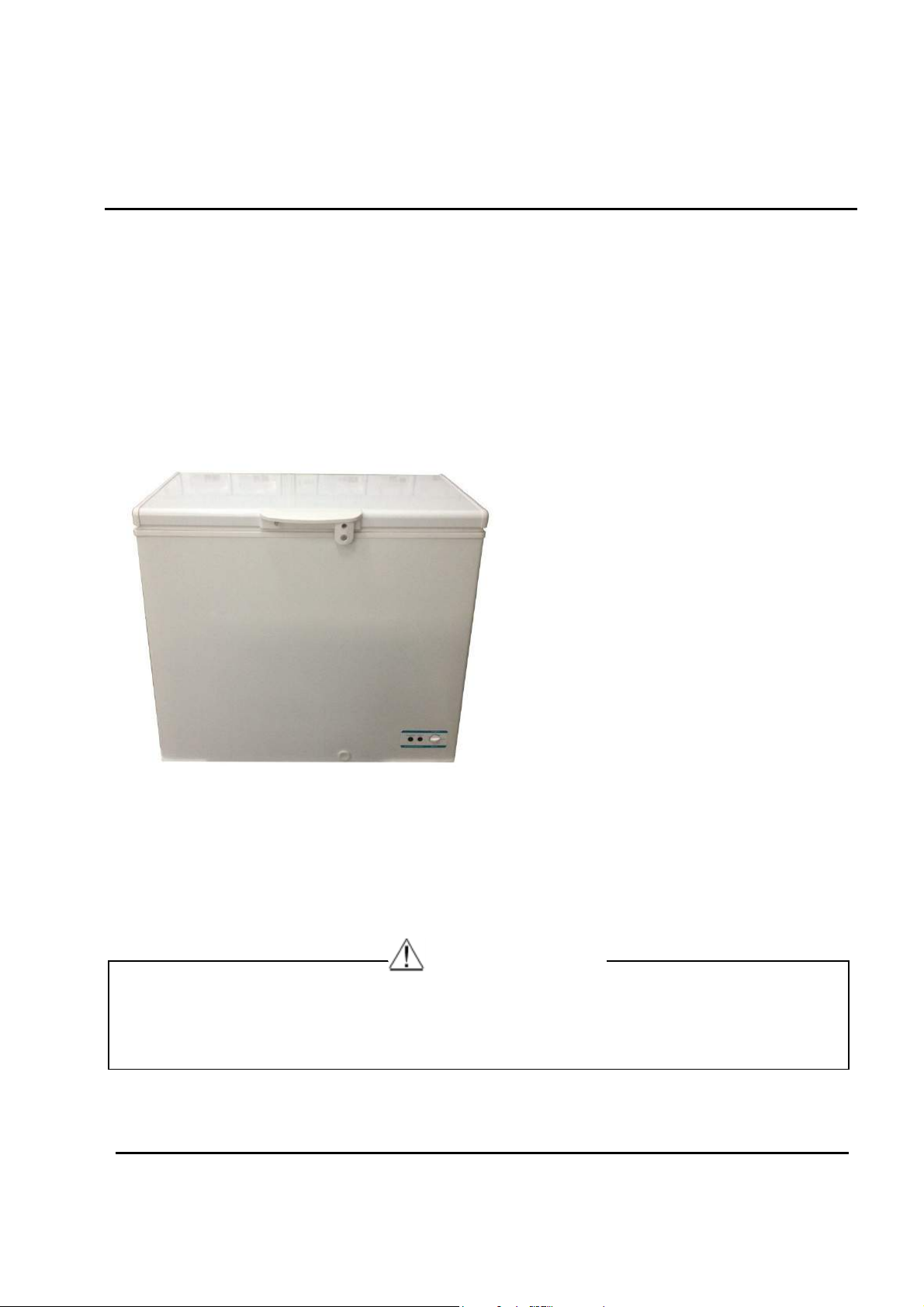

Chapter 2 Product Feature ........................................................................................................................ 5

2-1. SPECIFICATIONS .............................................................................................................................. 5

2-2. External view ...................................................................................................................................... 6

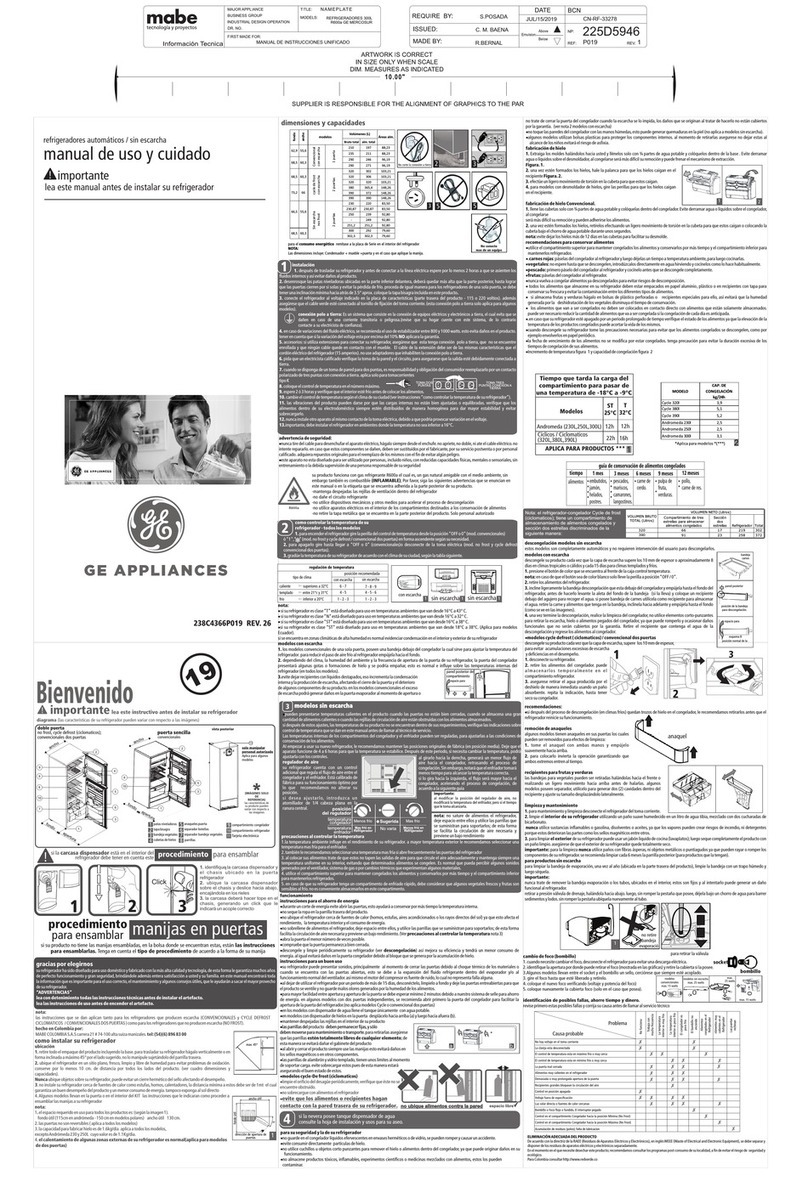

Chapter 3Installation, adjustments and maintenance ................................................................................. 7

3-1.Unpacking ........................................................................................................................................... 7

3-2.Adjusting ............................................................................................................................................. 7

3-3.Electrical Requirement ........................................................................................................................ 8

3-4.Defrost ................................................................................................................................................ 8

3-5. Cleaning............................................................................................................................................. 8

Chapter 4Disassembly ............................................................................................................................ 10

4-1. Door assembly (Door, hinge, hinge cover) ........................................................................................ 10

4-2. Compartment Grill assembly ............................................................................................................ 10

4-3. Control panel assembly

●(Panel, cover board, knob, indicator light) ..................................................... 11

4-4. Thermostat assembly

● ....................................................................................................................... 11

Chap

●ter 5Control and display system ...................................................................................................... 12

5-2. Starting the Freezer.......................................................................................................................... 13

Chapter 6System flow principle ............................................................................................................... 14

6-1.Refrigeration flow chart...................................................................................................................... 14

6-2. Refrigeration flow scenograph .......................................................................................................... 15

Chapter 7Circuit diagram

● ......................................................................................................................... 16

7-1. Briefprinciple diagram ....................................................................................................................... 16

Chapter 8Trouble shooting ...................................................................................................................... 17

8-1.Normal phenomena ........................................................................................................................... 17

8-2. Abnormal phenomena ...................................................................................................................... 19