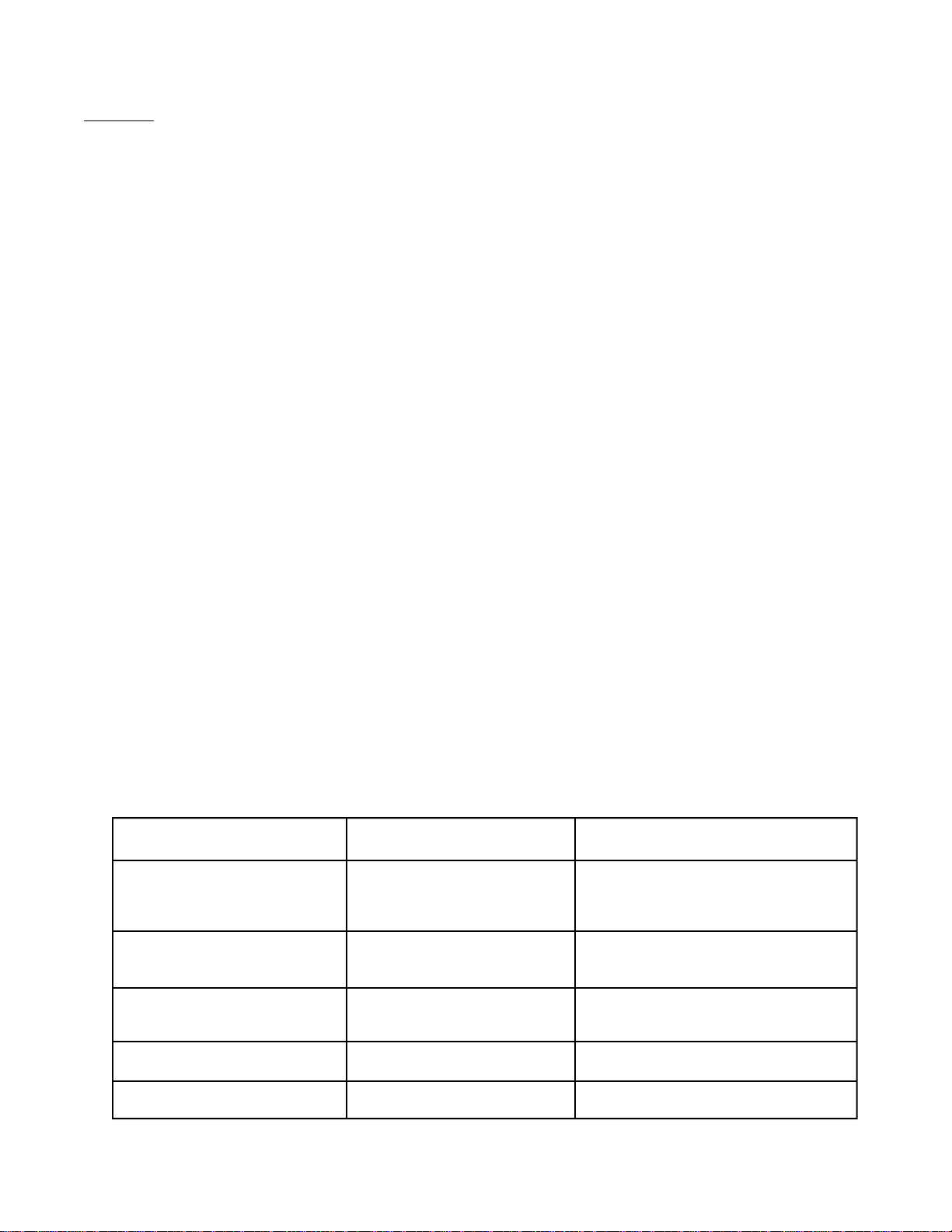

ASSEMBLY

(Refertofigure 1& 2)

1. Three major parts should be included in package:

(a) Hydraulic unit with pumping mechanism ( with

air motor equipped for Model JTA1000),

(b) Saddle unit, and

(c) 2 pieces of base half with bolts and washers.

2. Attach either one of the two base halves to the base

of the hydraulic unit, then secure using allen head

bolts and washers provided. Then apply the same

procedure to the other base half. Use torque wrench

to tighten to 30 lb.ft.. Do not overtighten.

3. Position the saddle unit above the ram piston, place

the saddle socket onto the ram piston. Secure using

the set screw.

4

BEFORE USE

1. Inspect jack before each use. Do not use if bent,

brokenorcrackedcomponentsarenoted.Ensurethat

castersmovefreely. Check for and tighten any loose

assemblies.

2. Verify that the product and the application are

compatible.

3. Press the release valve, ensure that saddle is fully

lowered.Removeshippingscrewandreplacewithvent

screw.(shippingscrew ison topof the oilfiller screw)

4. Ensure oil level is just below the rim of the oil filler

screwhole.

AirActuated Jacksonly (JTA1000)

1.Poura teaspoonof goodqualityair tool lubricantinto

the air supply inlet (See Figure 2). Connect to air

supplyandoperate for3 secondsto evenlydistribute

lubricant.

2. Air actuated product is fitted to accept the popular

1/4"NPTairnipple.Wheninstallingairnipple,ensure

thatthreadtapeorcompoundisusedonconnections.

Do not allow compound to enter the air supply inlet

orifice. Application of thread tape is acceptable, but

ensure that it is not applied beyond the first machine

thread.

OPERATION

Raise saddle:

Caution! For model JTA1000, do not operate the jack

bypumping thelift pedaland airpumppedalatthesame

time.

1. Pump foot pedal or press air pump pedal (Model

JTA1000)until saddlereachesdesiredposition.

2.Follow vehiclemanufacturer'srecommended

proceduresfor removingthe loadas outlinedin

vehicleservice manualor repairguide.

3.Secureload withprovidedchains. Ensureload's

center of gravity is centered on the saddle and load

isstablebefore movingjack.

Lower saddle:

Important! Be sure all tools and personnel are clear

beforelowering load.

Slowly, gently apply downward pressure to the release

valvepedal.

• Study, understand, and follow all printed materials

providedwith/on thisproduct beforeuse.

• Do not exceed rated capacity.

• Use only on hard, level surfaces capable of

supporting rated capacity loads.

• Use of this jack is limited to the removal,

installationandtransportation oftransmissions,

transfer cases and transaxles. Do not use a

transmission jack to tilt or support a vehicle.

• Ensure that center gravity of load is centered on

the saddle.

• Do not exceed 100tilt angle of the saddle

assembly in all directions.

• Adequately support the vehicle before starting

repairs.

• Use only chains provided.

• If loaded jack must be moved, make sure that the

load is secured, stable and in lowest position.

• This is a lifting and lowering device only.

• Transferload immediatelyto appropriatesupport

devicefor serviceorrepair.

• No alterations shall be made to this product.

• Failure to heed these markings may result in

personalinjuryand/or propertydamage.

!WARNING

Toavoid crushingand related

injuries:

NEVERworkon, underor

arounda loadsupportedonly

by a jack. Immediately

transfer the load to an

appropriatework station.

!WARNING