2.5. assignments and must be able to correctly interpret what described in this manual,

guaranteeing correctness, safety, as well as scrupulousness in the controls.

2.6. Possible consequential responsibilities from the employed, and authorized personnel, to the

installation or to the use of the machine are delegated to the customer buyer.

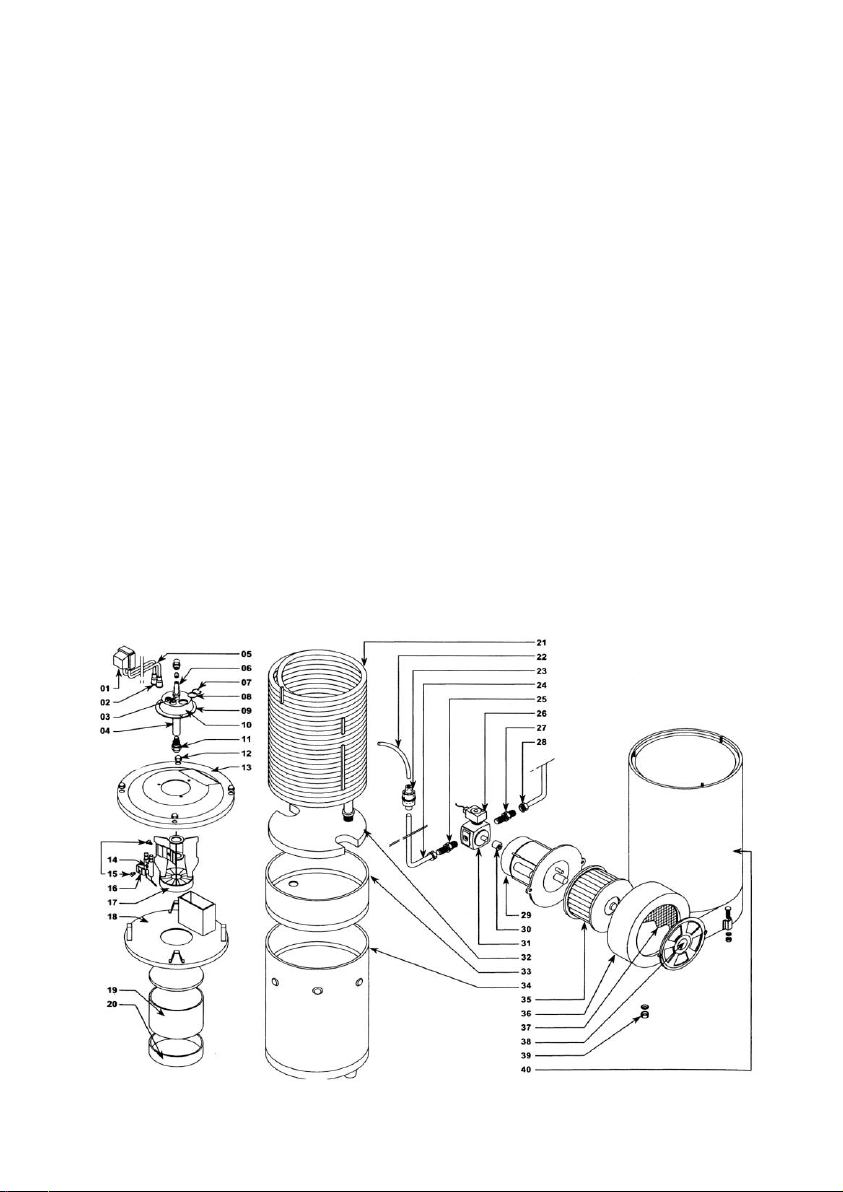

2.7. Those people that deal with the maintenance must dispose of knowledge and specific

(maintenance technician) competences that allow him to correctly interpret instructions and

sketches.

3. Accident prevention

3.1. The instructions furnished in this manual don't replace in any way the norms related to the

safety, to the installation and the use, to the technical data or the norms in force in the nation of

installation or use or the norms dictated of the common sense.

3.2. Technicians or maintenance technicians are obliged to notify any possible defects or

deteriorations that are able, in any way, to compromise the original safety of the plant.

3.3. The serial high pressure cleaner is not equipped for working in environments characterized by

particular conditions of inflammability or explosiveness; flameproof equipment is supplied only

and exclusively on specific request. It is forbidden to install the high pressure cleaner in

environments where inflammable materials are present or with particles it suspended in the air:

acids, inks, varnishes, resins, solvents, plastic subjects, etc.; follow the norms imposed by the

fire department.

3.4. During the filling of the fuel tank, the high pressure cleaner must be disconnected from the

electric net. At the same time it is absolutely forbidden to smoke or approaching the machine

with free flames during the filling of the fuel tank.

3.5. The hot water high pressure cleaners are projected for an economic combustion, clean and

respectful towards the environment and deprived of the residual exhaust gases. Despite this,

inhaling high quantity or percentages of gases, such CO, is harmful and lethal particularly.

3.6. If the high pressure cleaner is installed or used in places and closed (like garages or

establishments) environments, it is necessary to predispose a device of evacuation of the gases

together with a recycling of the air supply and for the restoration of the air in the place or in the

closed environment.

3.7. Never obstruct the terminal of the chimney; with objects, lance or gun, in proximity of the outlet

of the smokes. It’s also considered highly dangerous, both for the smokes and also for the

elevated temperatures reached. To avoid possible burns, inform technicians and operators

about it.

3.8. The high pressure cleaner and its plant as the place and the environment, are forcedly exposed

to the water and the damp that injure the natural conditions of isolation of the plant. Don't use

therefore unsafe electric cables, thorns or plugs, and sockets; to check the integrity and the

isolation of the electric cable, together with the equipment of the operators. Don't absolutely

touch the thorn or the plugs with wet hands or feet. To avoid accidental switching on, turn the

interrupter on OFF before inserting or disconnecting the power supply. Don't pull the high

pressure cleaner using the electrical or to extract its thorn from the socket.

3.9. Use with extreme care the chemical detergents not to deteriorate the environment (degradability

90%), parts or components of the machine, according to the updating of the legislative decree.

Besides, always check the degradability and the aggressiveness of the used detergents. Never

use acids, inks, solvents, liquid oily, varnishes, resins, etc…

3.10. The "cold" starting of the high pressure cleaner can cause some serious damages to the pump

and the circuits; the standstill prolonged at temperatures under 0°C could cause breakups and

damages to the pump and the pipes; therefore the emptying of the machine is advisable.

3.11. Always protect the high pressure cleaner from the atmospheric agents, from the cold and from

the frost.

3.12. Never direct the jet of water towards people (not even to clean their clothes or their shoes) or

animals, nor the machine itself or any objects under electrical tension.

3.13. Lance and gun, although equipped with proper hilts, they have a modest counterblow to the

departure of the jet; to maintain them with strength with both the hands. Do never touch the jet

of water during the operation of the idropulitrice.

3.14. If some defects, damages or deteriorations on the machine are found, disconnect it

immediately, and call an assistance authorized center assistance authorized or to the supplier.

3.15. Don't leave never, without overseeing, the high pressure cleaner working in presence of

children.