PM150-CO2 Portable Gas Monitor

REV – 1.0 [34-2900-0211-5] 2 |Page

1 General Information ....................................................................................................................................................... 4

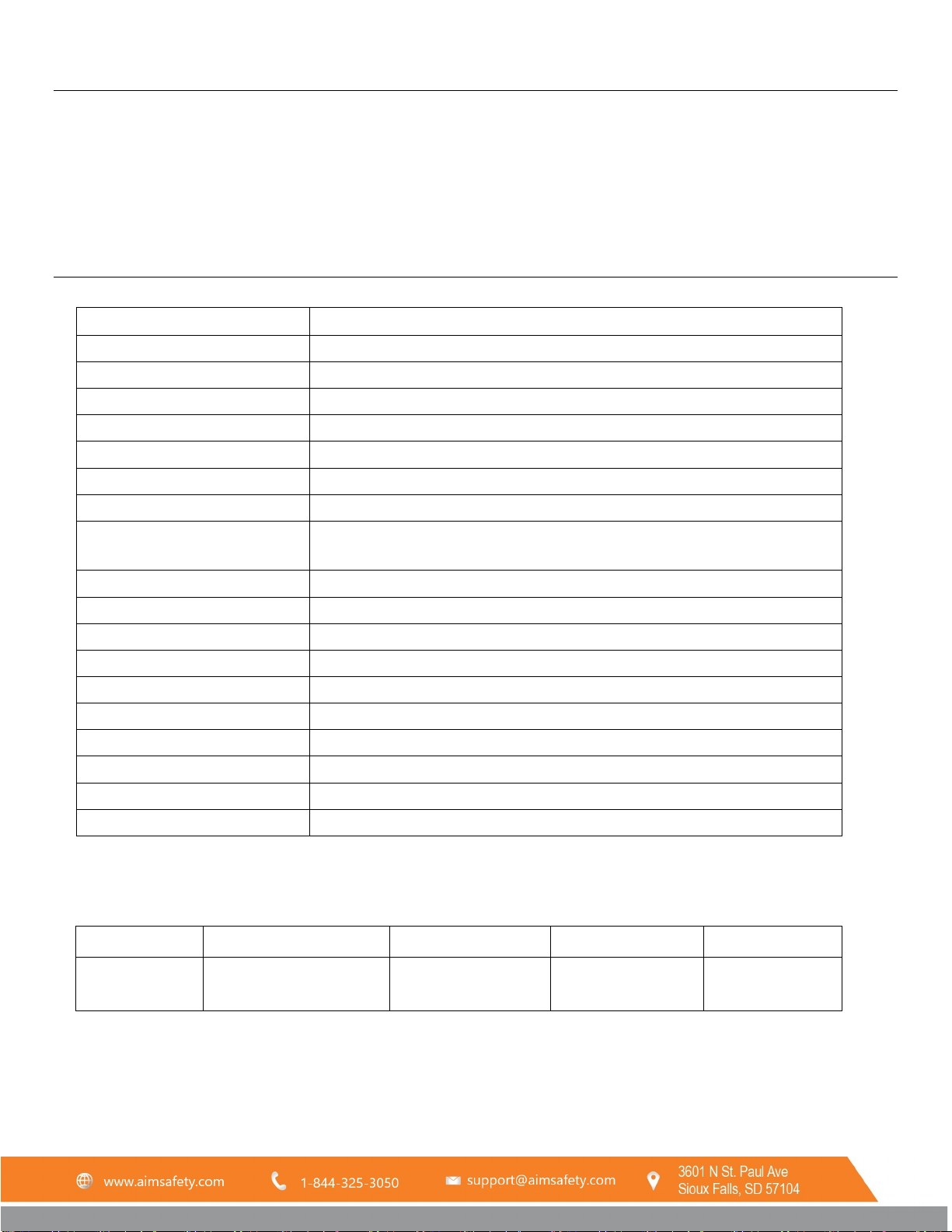

2 Specifications .................................................................................................................................................................. 4

2.1 PM150-CO2 Specifications...................................................................................................................................... 4

2.2 Sensor Specification ................................................................................................................................................ 4

3 Product Overview............................................................................................................................................................ 5

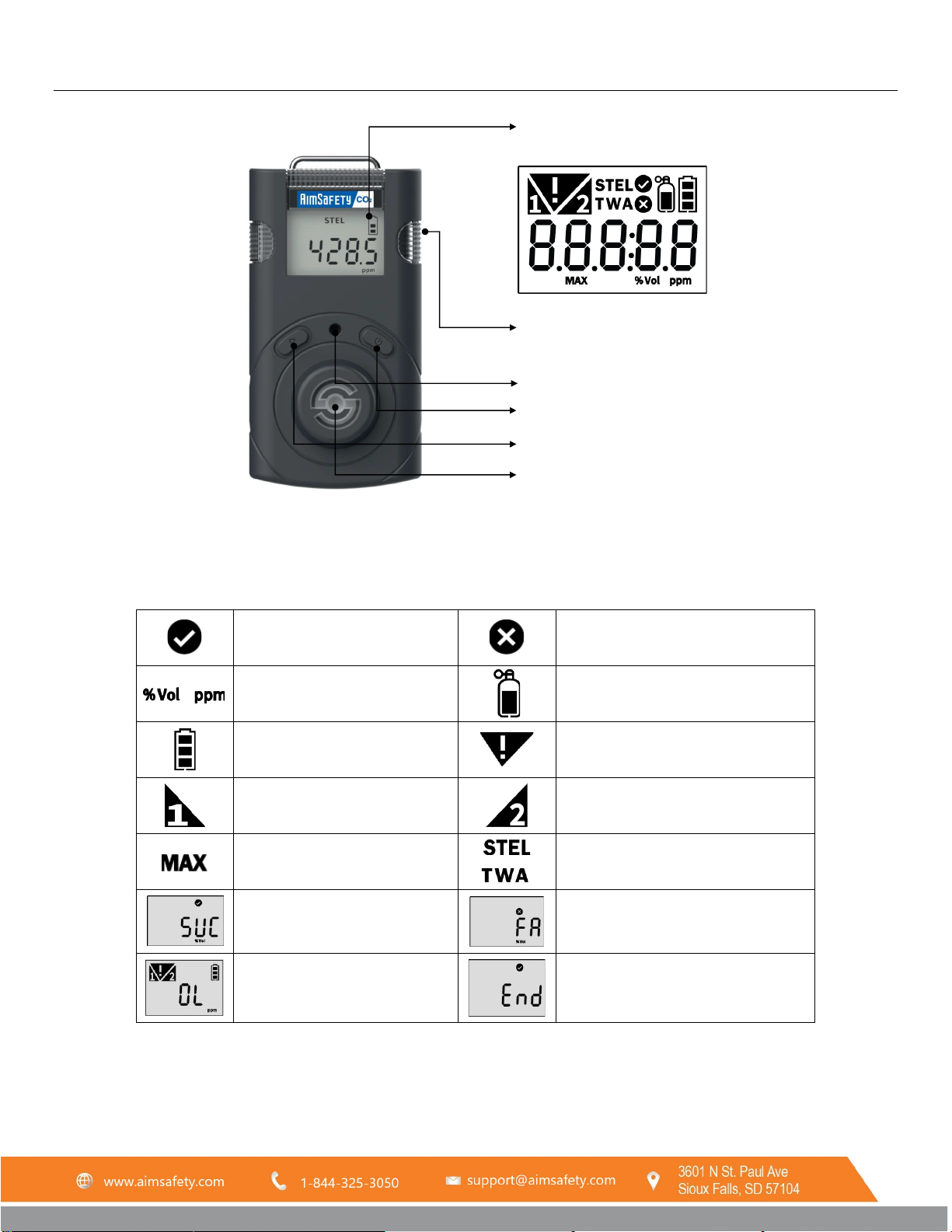

3.1 Monitor Overview................................................................................................................................................... 5

3.2 Display Overview..................................................................................................................................................... 5

4 Activation ........................................................................................................................................................................ 6

4.1 Activating the PM150-CO2...................................................................................................................................... 6

4.2 Error Messages........................................................................................................................................................ 6

4.3 Bump Test ............................................................................................................................................................... 7

5 Mode............................................................................................................................................................................... 8

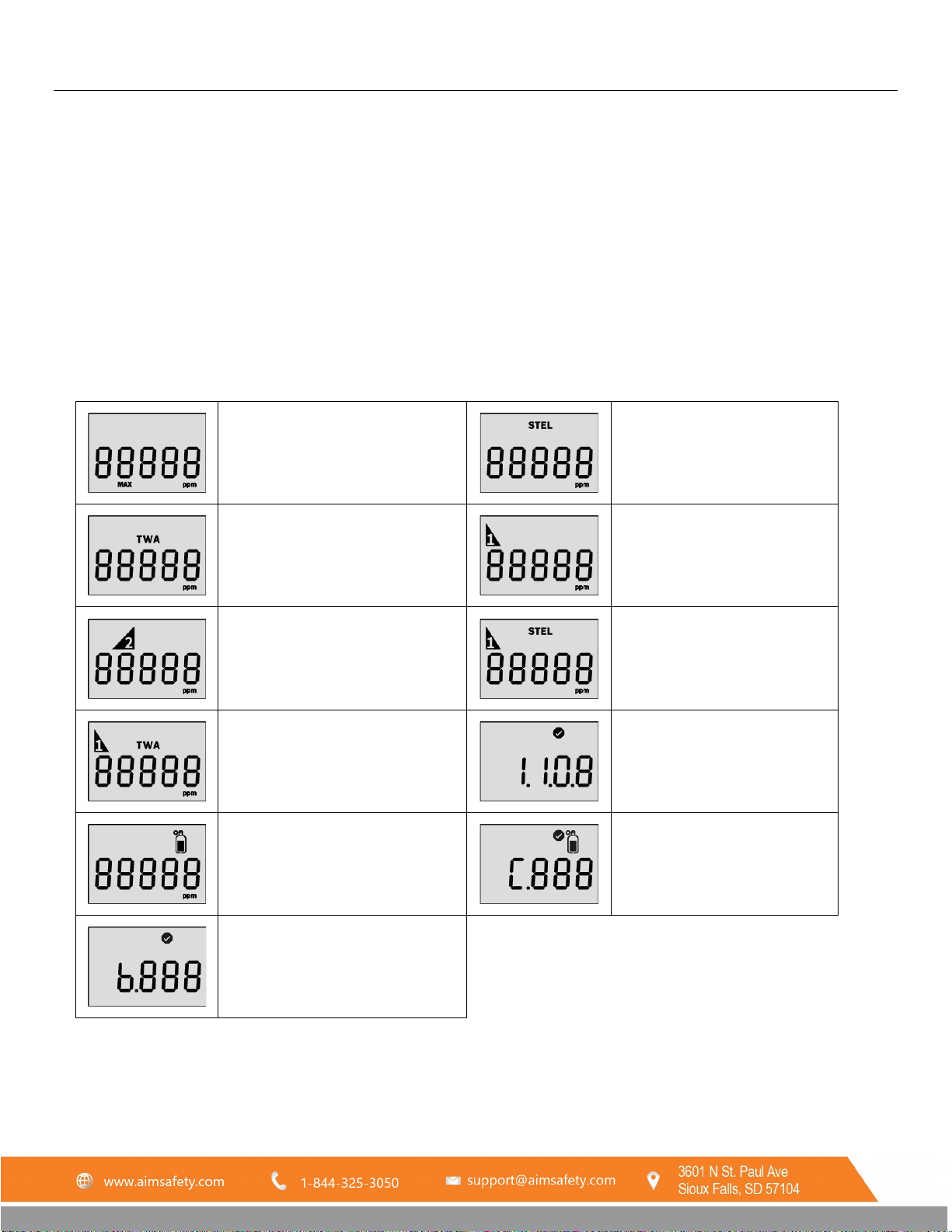

5.1 Measuring Mode..................................................................................................................................................... 8

5.2 Display Mode .......................................................................................................................................................... 8

5.3 Settings Mode ......................................................................................................................................................... 9

5.4 Setting Mode Symbols............................................................................................................................................. 9

6 Setting Mode................................................................................................................................................................. 10

6.1 Alarm Activation.................................................................................................................................................... 10

6.2 Adjust alarm set points ......................................................................................................................................... 10

6.3 Data Log ................................................................................................................................................................ 10

7 Menu Screens................................................................................................................................................................ 11

7.1 Menu Flow Chart................................................................................................................................................... 11

7.2 Clear Max (Peak Values)........................................................................................................................................ 12

7.3 Clear STEL and TWA............................................................................................................................................... 12

7.4 Adjust Unit ............................................................................................................................................................ 12

7.5 Factory Reset......................................................................................................................................................... 12

7.6 Self-Test................................................................................................................................................................. 13

8 Calibration..................................................................................................................................................................... 14

8.1 Calibration Gas Values .......................................................................................................................................... 14

8.2 Zero (N2) Calibration............................................................................................................................................. 14

8.3 Span Calibration .................................................................................................................................................... 15

9 Software Manager ........................................................................................................................................................ 16

9.1 Software Overview................................................................................................................................................ 16

9.1.1 Read .............................................................................................................................................................. 17

9.1.2 Write ............................................................................................................................................................. 17

9.1.3 Calibration..................................................................................................................................................... 17

9.1.4 Log................................................................................................................................................................. 17

9.1.5 Firmware Upgrade ........................................................................................................................................ 17

9.2 Window menu....................................................................................................................................................... 18

9.2.1 Menu – File.................................................................................................................................................... 18

9.2.2 Menu – Tools................................................................................................................................................. 18

9.2.3 Menu – Device............................................................................................................................................... 18

10 Maintenance ............................................................................................................................................................. 19

10.1 Sensor Replacement ............................................................................................................................................. 20

10.2 Battery Replacement ............................................................................................................................................ 20

11 Battery Charging ....................................................................................................................................................... 21

11.1 To charge the battery:........................................................................................................................................... 21