entire audio spectrum and far beyond, which no other format can deliver.

The analog LP is not restricted to 16 bits and a limited frequency band, but has 700 bits - so to speak - and the minute upper harmonics which

digital formats are missing. The simple reason is that the original LP is analogous in nature.

Or, to be more precise: analogous to nature.

PERFORMANCE VERSUS CD

If your CD outperforms your analog setup, than you do not have the right combination of components. In other words you forgot about

"system building". There are some general and specific do's and don'ts. Here are a few:

- Look for voluptuous sound, yet well controlled, look for realism.

- Look for a good, spacious mid band.

- Do not connect low efficiency loudspeaker systems to a 10 or 25 Watt tube amplifier or to a high current amplifier, but use a power amplifier

delivering current stored in a large reservoir of Micro Farads.

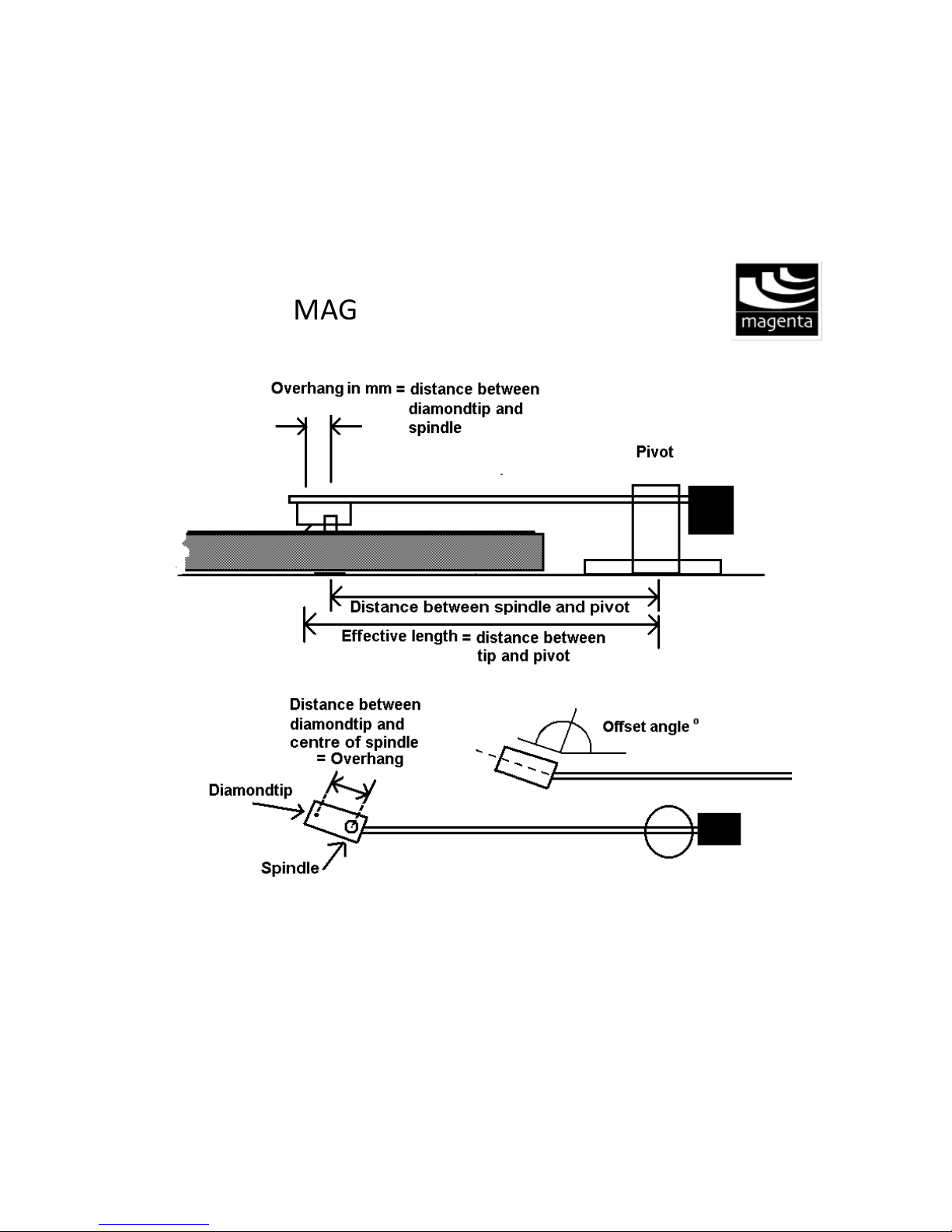

- Match cartridge and arm properly: mass (weight of the arm) in relation to compliance.

- Choose the right preamplifier to match the impedance and/or capacitance of your cartridge. Make the necessary adjustments.

- Carefully position your loudspeakers in the listening environment.

- Follow your taste and ears. Go to live concerts of classical music and jazz. There you will find that high-end does not exist in reality, only

realism.

- Do not take the PA set-up during a live concert of your favorite rock band as a reference. Because that sound is no reference at all. Many of

those experts who move the faders have a hearing problem. And soon you may have one too.

- Be well advised, but forget about the hype which surrounds so many components and is repeated by so many and far too often.

- Do not be distracted and confused by a member of a forum who says that this page gives - in his opinion - at some instances incorrect advice.

Only believe him if he points out what is incorrect. You will notice that he never does.

Even if new and more complex and high resolution digital formats are being developed and there are no appropriate players for

these formats, the recording can be engraved in a vinyl record and can be fully enjoyed. Even hundred years from now.