1.2 APPLICABLE WARNING SIGNS

MAGNETIC FIELD STRENGTH

High magnetic field strengths during magnetising can lead to

health problems and negative eects on implants.

• Follow all general and specific regulations for the prevention

of accidents.

• Observe safety distances during magnetising.

RISK OF INJURY FROM HEAVY OBJECTS

Heavy objects may injure hands:

• Do not grip between objects and magnetising coil when

loading and unloading.

• Wear protective gloves.

SKIN IRRITATION THROUGH MATERIALS

Components in the chemical materials may lead to skin irrita-

tion or other health risks.

Always follow the safety instructions in the manufacturer’s

Safety Data Sheet when handling chemical materials.

HIGH ELECTRIC VOLTAGES CAN CAUSE LETHAL ELECTRIC

SHOCK AND BURNS

Work on the electrics of this unit must only be carried out:

• in compliance with applicable standards at the installation site;

• only by a qualified electrician.

IN AN EMERGENCY:

Immediately disconnect the ETT from the power supply.

The mains switch serves as a mains isolation.

• OFF position is marked ‘0’.

• ON position is marked ‘1’.

With the switch in the OFF position, the machine is isolated from the power supply

and the switch can be secured with a padlock.

1.3 EXPOSURE TO MAGNETIC FIELDS

DANGER TO LIFE FOR PERSONS WITH CARDIAC PACEMAKERS

Magnetic fields can interfere with cardiac pacemakers, insulin

pumps and other implanted devices.

DO NOT USE THIS EQUIPMENT:

• if you have a pacemaker, insulin pump or other implanted device.

• if you are pregnant.

• if you are under 16 years of age.

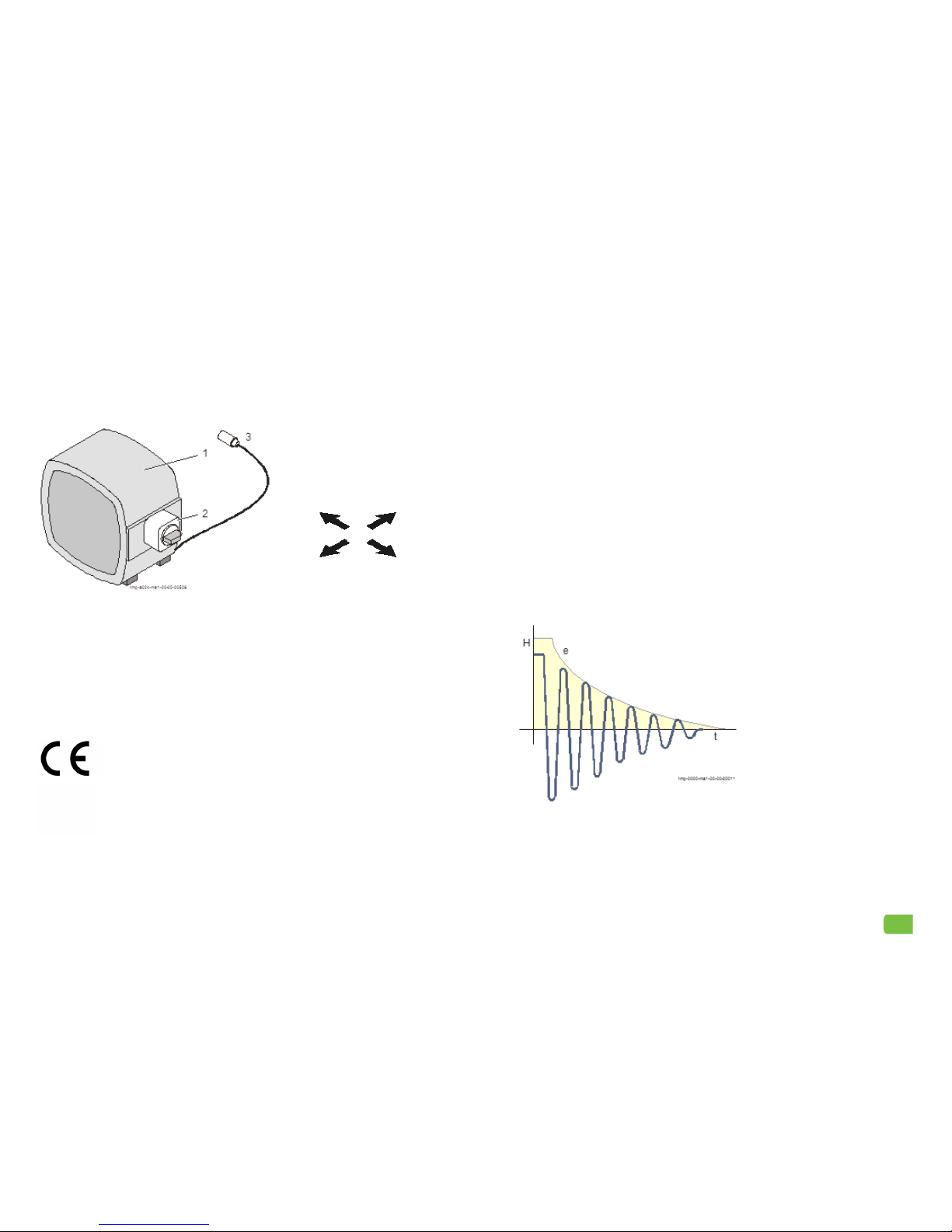

The grey shaded zone in this diagram

(right) shows the area of increased expo-

sure to magnetic fields. The operator must

measure and mark out the safety distance

in their own workplace, and maintain that

distance from the magnetising device

during operation:

• peoplewithoutbody-implanteddevices:

0.5 m / 20”

• people with body-implanted devices

(e.g. pacemakers): 5 m / 16’ 5”

In addition, the operator must ensure that

• only authorised and trained personnel are working in these areas

• the permissible values for short-term and partial body exposure are not

exceeded

• personal protective equipment (PPE) is used to prevent over-exposure.

Important: magnetic fields can penetrate through walls!

The specified safety distance results from the limits set out in the accident

prevention regulations BGV B11 as of June 2001 of the International Directive

for the Limitation of Exposure by Temporary Change in Electrical, Magnetic and

Electromagnetic Fields (ICNIRP), 1998.

According to Accident Prevention Regulation BGV B11, the ETT machine is assigned

the magnetic exposure group 1. The exposure group 1 covers areas with controlled

access, like work places.

S = area of increased exposure

2