54

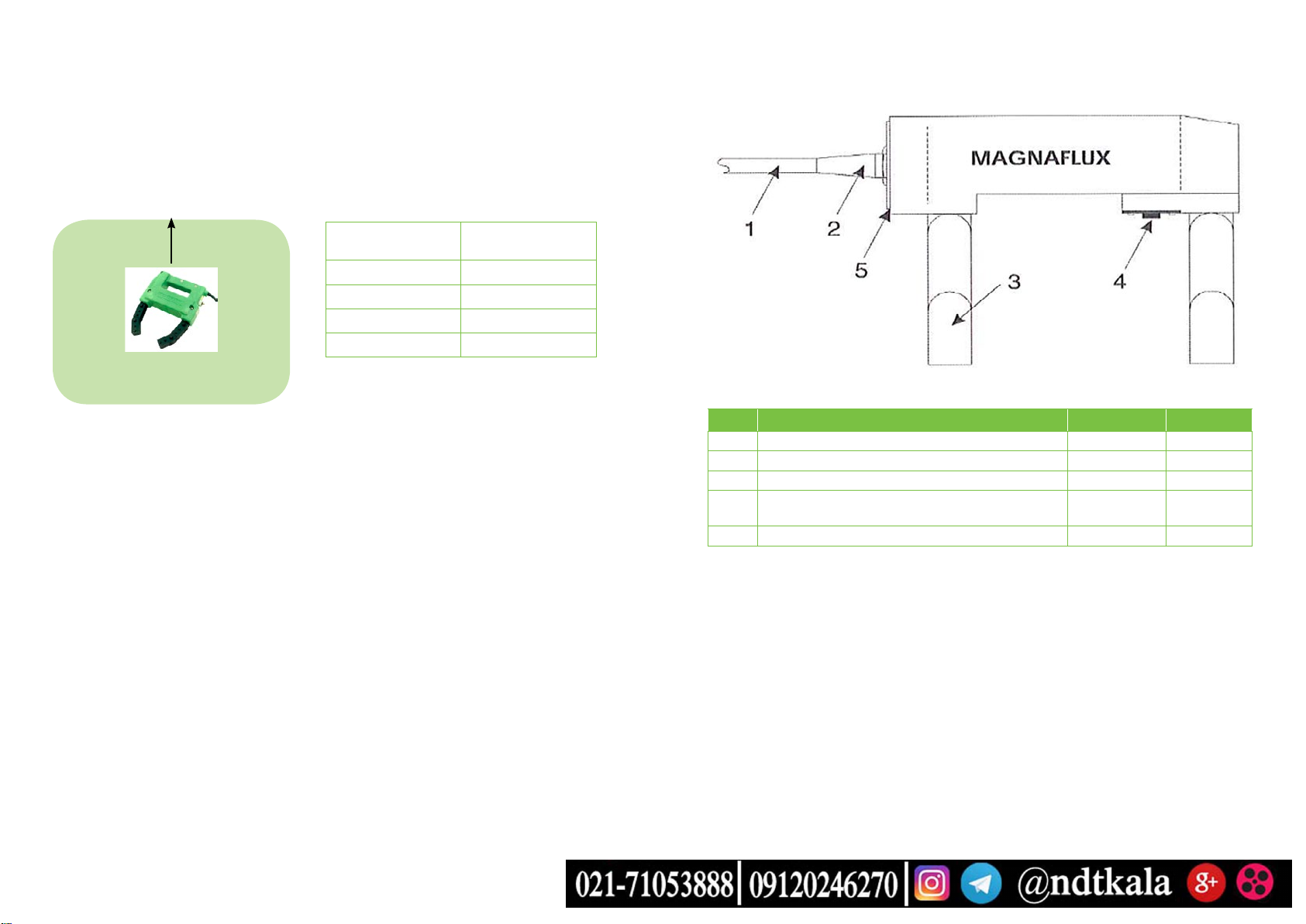

2. OPERATING THE YOKE

2.1 PRINCIPLE OF OPERATION

When the Yoke is connected to a suitable power source, depressing the ‘Push to test’

switch creates an intense magnetic eld between the Yoke legs. As the Yoke is applied

to a steel plate, the magnetic circuit is closed, and the magnetic eld enters the plate

between the legs of the Yoke at and near the surface. A surface crack across this eld cuts

the magnetic circuit, the two sides of the crack become opposite poles of a magnet and

a leakage eld occurs in the air above the crack. Magnetic particles are attracted by this

leakage eld and mark its location.

2.2 SAFE USE OF THE YOKE

Our yokes manufactured to the highest technical standards. You can ensure safe

operation of your yoke by observing general safety and accident prevention regulations,

including the advice outlined below.

Before using the Yoke:

• Familiarise yourself with the yoke’s construction and method of operation. If necessary,

contact the manufacturer - Magnaux GmbH - for instruction/training.

• Ensure it is physically undamaged.

• Ensure the cable is free from cuts which expose the wiring.

• Tighten the articulated joints if they are excessively loose.

During use:

• Follow the operating instructions carefully.

• Observe the safety distances (see section 1.1) and time limit for usage.

• Wear appropriate personal protective equipment to protect yourself from over-

exposure to electromagnetic elds.

• Do not allow untrained personnel to operate the yoke; improper use of the yoke can

be hazardous to health.

• Only allow authorised personnel who are aware of the potential dangers of electro-

magnetic exposure into the areas where the yoke is being used.

• Do not attempt to repair or rebuild the yoke unit.

2.3 INSTRUCTIONS FOR USE

1. Place the Yoke on the workpiece perpendicular to the direction of the cracks. The

double-jointed articulated legs can be moved in two directions at each joint.

2. Adjust the spacing between the legs to between 25 and 250mm. If the part is an

irregular shape, contour the feet to ensure a good at contact point.

3. Trigger the switch and apply the inspection medium (wet or dry). Surface crack

indications will form immediately (for enhanced sensitivity, use a uorescent magnetic

ink with a high-intensity black light).

4. Repeat as required, moving the Yoke over the part. Each placement of the Yoke will

nd cracks in a 150 x 150mm area.

Laminar magnetic iron provides maximum efciency with light weight. The trigger switch

is easily operated without changing hand positions.

Magnetic contact exists only between the Yoke and the test piece, so the switch, which

is completely enclosed by a rubber gasket, is the only break in the electrical circuit. This

means that arcing on the part itself is impossible.

To detect transverse cracks in mounted spindles, rear axles and other light parts, the Y6

Yoke can be supplemented by a magnetising coil (e.g. Magnaux L-10 Magnetising Coil).