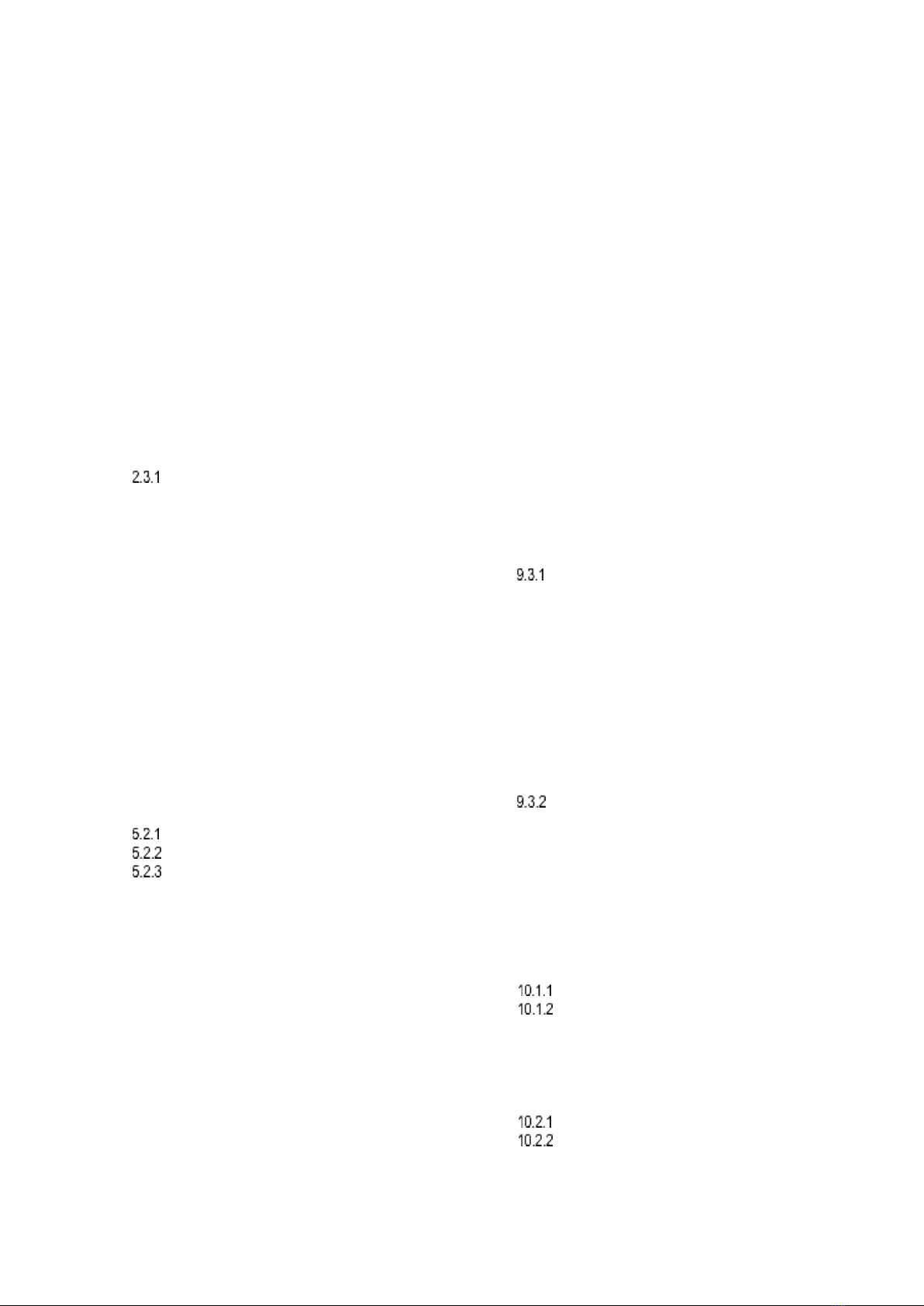

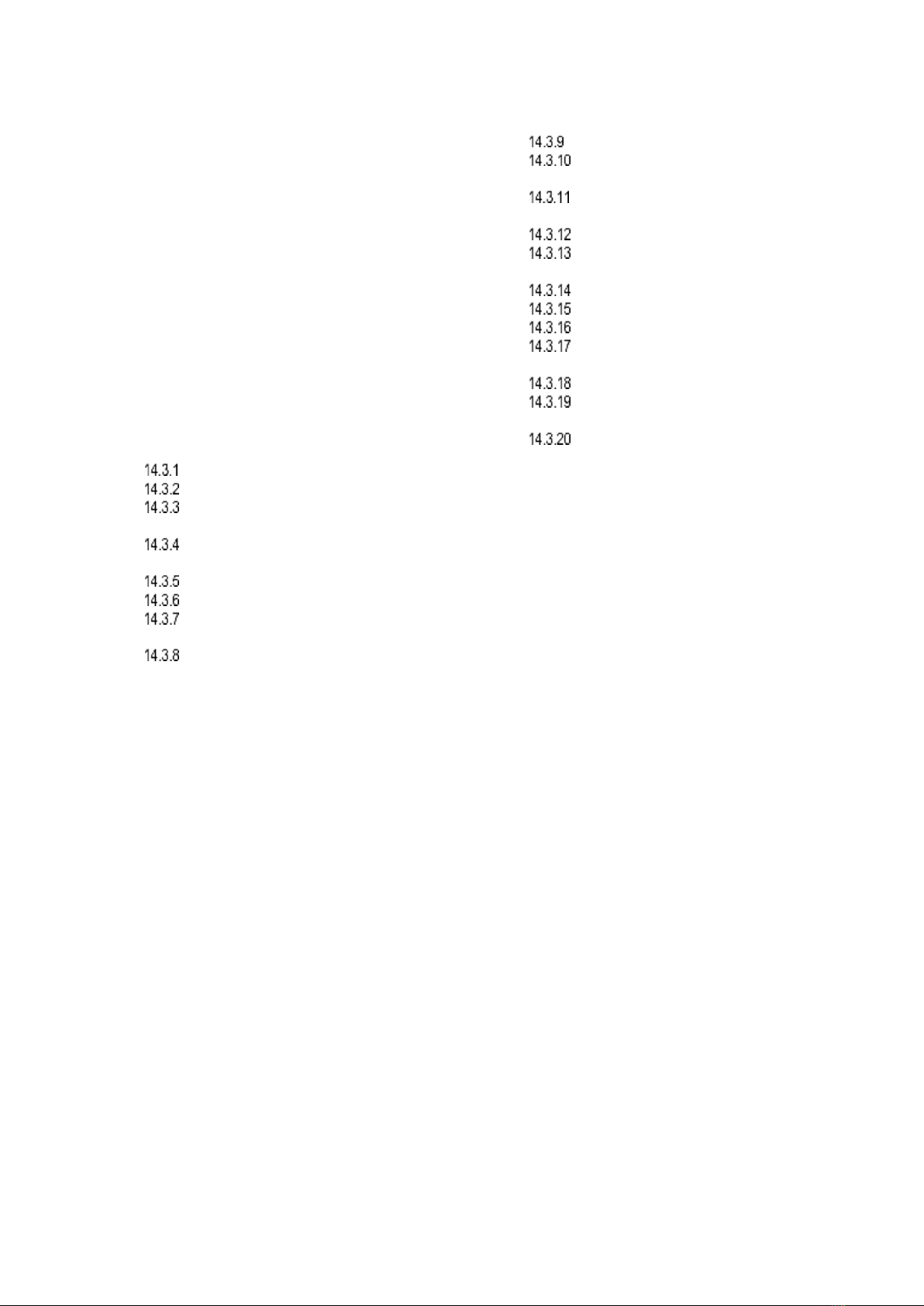

Analytical Index

A.DEFINITIONS ................................................5

B.WARNING ...................................................5

C.CAUTION.....................................................7

D.NOTES........................................................7

1. DESCRIPTION .............................................8

1.1 INTENDED USE .............................................8

1.2 OPTIONAL ITEMS COMPATIBLE WITH THE

PRODUCTS 9

2. UNPACKING THE PRODUCT ......................10

2.1 INITIAL CHECKS ..........................................10

2.2 PARTS AND ACCESSORIES............................11

2.3 OPTIONAL ACCESSORIES THAT CAN BE PURCHASED

FOR OXYMAG...............................................................12

PROTOCOL USED FOR DATA COMMUNICATION

WITH EXTERNAL DEVICES ...............................................17

3. DESCRIPTION OF THE DISPLAY.................20

3.1 MODES .....................................................20

3.2 ALARMS,MONITOR AND STATUS ....................20

3.3MONITOR,MENUS AND CHARTS.....................20

3.4 SETTING THE VENTILATION PARAMETERS .........20

4. PREPARATION FOR USE ...........................21

4.1 ASSEMBLING OXYMAG –TRANSPORT VENTILATION

21

4.2 NONINVASIVE VENTILATION MASK ...................23

4.3 POWER CONNECTION ..................................24

4.4 MOUNTING THE VERTICAL SUPPORT................25

5. CHECKS BEFORE USE ..............................27

5.1 INITIAL PROCEDURES ...................................27

5.2 VENTILATOR SETTINGS ................................28

NORMAL STARTUP SEQUENCE ..................30

TEST SEQUENCE ....................................33

FAILURE DIAGNOSIS................................34

6. CAPNOGRAPHY SENSOR (ETCO2).............35

6.1 INSTRUCTIONS FOR USE...............................35

6.2 ASSEMBLING THE SENSOR............................35

6.3 POSITIONING THE SENSOR............................37

6.4 PROCEDURE TO RESET THE SENSOR..............38

6.5 INFORMATION REGARDING LED .....................38

6.6 PREVENTIVE MAINTENANCE OF ETCO2SENSOR39

6.7 TECHNICAL SPECIFICATIONS OF THE

CAPNOGRAPHY............................................................40

7. OXIMETER (MASIMO) ................................45

7.1 OPERATION PRINCIPLE ................................45

7.2 SUMMARY OF BLOOD CALIBRATION TEST ........49

7.3 LOW PERFUSION TEST SUMMARY....................49

7.4 SENSOR ASSEMBLY ......................................49

7.5 OXIMETER SPECIFICATION.............................50

8. DESCRIPTION OF MODES..........................52

8.1 VCV –VOLUME CONTROLLED VENTILATION.... 52

8.2 PCV –PRESSURE CONTROLLED VENTILATION .. 54

8.3 PLV –LIMITED PRESSURE VENTILATION .......... 56

8.4 V-SIMV –SYNCHRONIZED INTERMITTENT

MANDATORY VENTILATION –VOLUME CONTROLLED CYCLE. 58

8.5 P-SIMV –SYNCHRONIZED INTERMITTENT

MANDATORY VENTILATION –PRESSURE CONTROLLED CYCLE60

8.6 CPAP/PSV –CONTINUOUS PRESSURE

VENTILATION WITH PRESSURE SUPPORT ........................... 62

8.7 DUALPAP –BI-LEVEL CONTINUOUS POSITIVE

AIRWAY PRESSURE VENTILATION .................................... 64

8.8 APRV –AIRWAY PRESSURE RELEASE VENTILATION

(MODE OBTAINIED WITH INVERTED RATIO IN DUALPAP) .... 66

9. ALARMS AVAILABLE.................................68

9.1 DESCRIPTION OF ALARM CONTROL ................. 68

9.2 SETTING ALARMS ....................................... 78

9.3 ALARM TEST .............................................. 78

ADJUSTABLE ALARM TEST ........................ 78

9.3.1.1 PRESSURE ALARM .................................. 78

9.3.1.2 PEEP ALARM ........................................ 78

9.3.1.3 MINUTE VOLUME ALARM (MV)................... 79

9.3.1.4 RESPIRATORY RATE ALARM ..................... 79

9.3.1.5 VOLUME ALARM ..................................... 79

9.3.1.6 FIO2 ALARM.......................................... 79

9.3.1.7 ETCO2 ALARM ...................................... 79

9.3.1.8 PULSE RATE ALARM ................................ 79

9.3.1.9 CO2 ALARM .......................................... 79

9.3.1.10 SPO2 ALARM .................................... 79

9.3.1.11 APNEA ALARM ................................... 80

CRITICAL ALARM TEST.............................. 80

9.3.2.1 DISCONNECTION................................ 80

9.3.2.2 NO AC POWER.................................. 80

9.3.2.3 LOW BATTERY ................................... 80

9.3.2.4 OBSTRUCTION................................... 80

9.3.2.5 LOW O2 SUPPLY................................ 80

9.4 MANUAL VENTILATION OF THE PATIENT........... 80

10. CLEANNING AND STERILIZATION ..............81

10.1 EQUIPMENT CLEANING ............................ 81

EXTERNAL VENTILATOR SURFACES ............ 81

RESPIRATORY CIRCUIT,PROXIMAL FLOW

SENSOR AND EXHALATION VALVE..................................... 81

10.1.2.1 WASH.............................................. 81

10.1.2.2 RINSE.............................................. 81

10.1.2.3 DRYING ........................................... 82

10.2 DISINFECTION........................................ 82

EXTERNAL PARTS .................................. 82

RESPIRATORY CIRCUIT,EXHALATION VALVE,

PROXIMAL FLOW SENSOR AND SILICONE LINE ..................... 82

10.3 STERILIZATION....................................... 82

10.4 PROCESSING METHODS........................... 83