SAFETY RU ES

Reports on accidents show that care-

less use of machinery causes a high

percentage of accidents. You can avoid

many accidents by following the safety

rules on these pages. Study these rules carefully

and enforce them on the job

.

SAFETY BEFORE STARTING OR

OPERATION

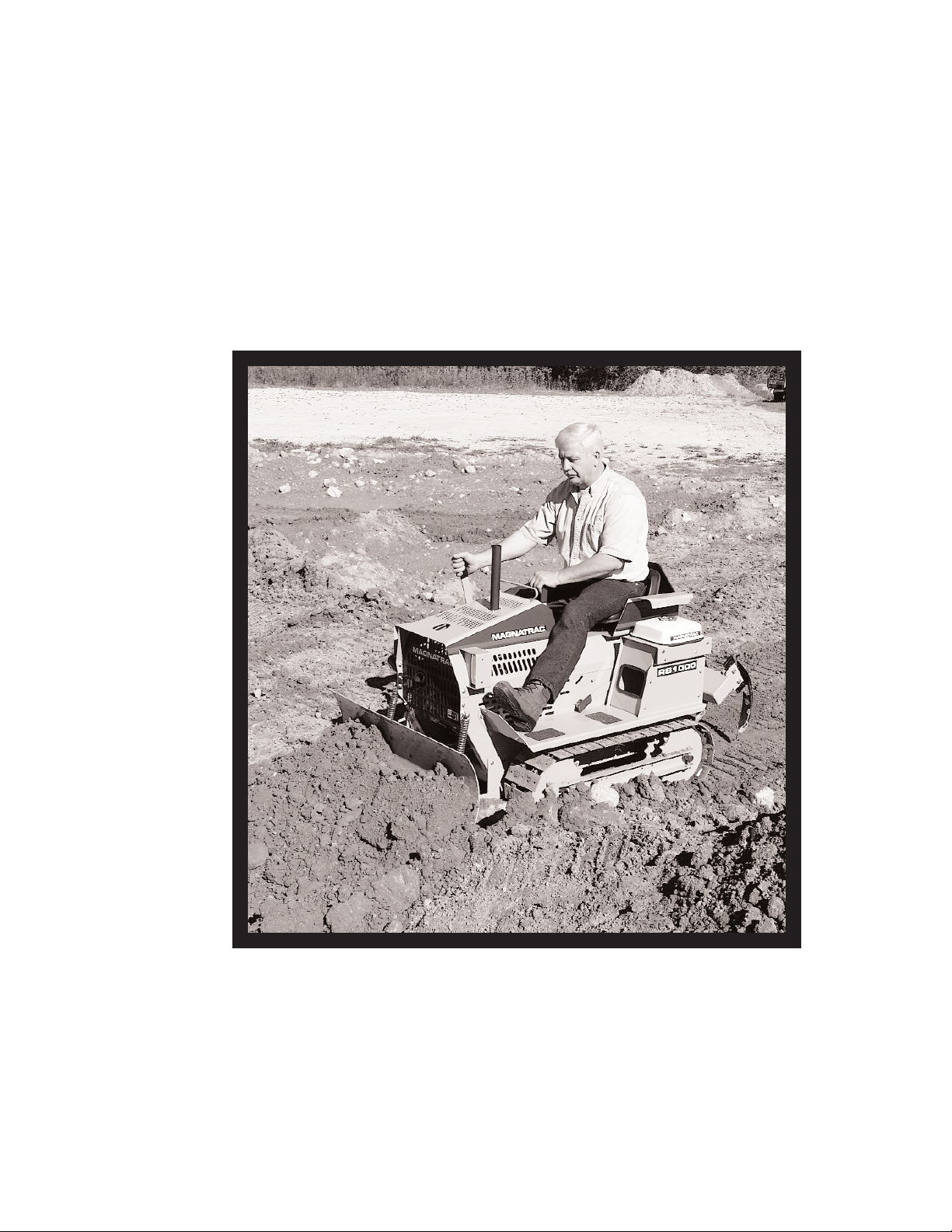

The Crawler should be operated only by persons

approved to do so.

Clothing worn by the operator should be fairly tight

and belted.

Fasten a first aid kit to the Crawler.

Fasten a fire extinguisher to the Crawler. Keep

the extinguisher fully charged. Learn to use it cor-

rectly.

f the Crawler has an unsafe condition, do not op-

erate. Put a tag on the Track Drive Controls.

Do not start or operate the Crawler unless you are

in the operator’s seat.

Before you start the Engine, be sure there is

plenty of ventilation.

Keep hands, feet, and clothing away from power-

driven parts.

Fasten a slow-moving vehicle sign to the rear of

the Crawler.

Guards, shields, and other protective devices

must be in place and in good condition.

Before you start or operate the Crawler, clear the

area of all persons and obstacles.

OPERATION SAFETY

When you operate the Crawler, do not allow any-

one to ride on the Crawler or its equipment.

Drive at safe speeds at all times, especially on

rough ground and hillsides.

Carry the Bucket or Blade as low as possible at

all times, especially when you work on a hillside

or back up a steep hill.

Do not drive too close to the edge of a ditch or ex-

cavation.

Watch for overhead wires. Do not touch wires

with any part of the Crawler or its Attachments.

Do not leave your Crawler unattended with the En-

gine running.

Keep work areas as level as possible.

When loading logs with the Log Forks, make sure

the logs are balanced.

When you drive out of a ditch or excavation, or up

a steep hillside, or when Crawler is hitched to a

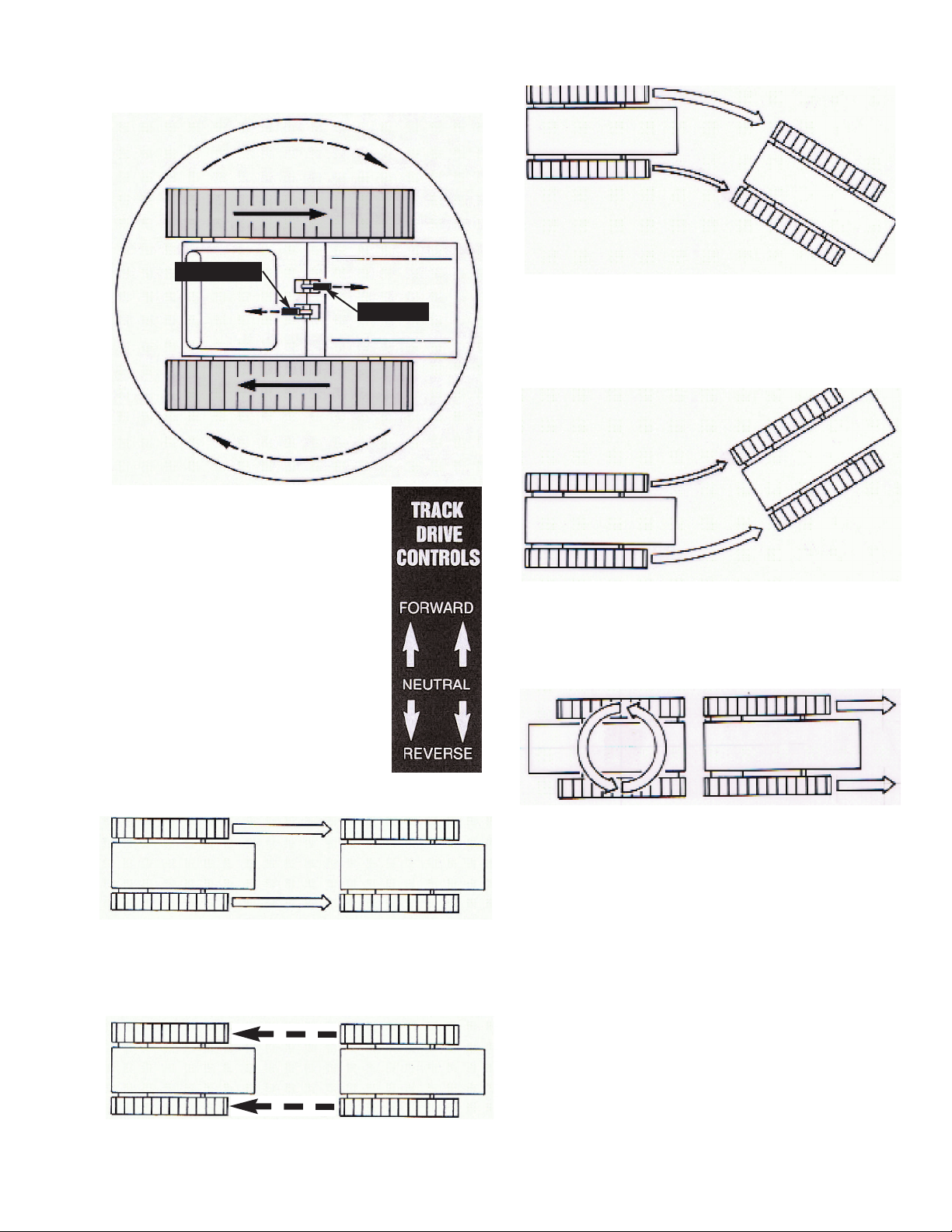

heavy load, engage Track Drive Controls slowly. f

the front of the Crawler comes off the ground, re-

lease Track Controls immediately.

Do not use the Crawler as a battering ram.

Do not guide cable onto Winch Drum with your

hands.

When you drive the Crawler on a road, use the

correct lights to warn operators of other vehicles.

Before you move any equipment, be sure all per-

sons are away from the Crawler.

When the Crawler is operating, only the operator

should be on it.

f it is necessary to make checks with the Engine

running, always use two people...the operator at

the controls should be able to see the person

doing the checking

KEEP HANDS AWAY FROM MOVING PARTS!

BEFORE YOU DISMOUNT:

Move Track Drive Controls to neutral.

Engage Parking Brake ever

ower all equipment to the ground.

Stop Engine and remove the key.

2