LOWLANDER MK4 MANURE SPREADER –INSTRUCTION & SPARES MANUAL

PAGE

4.8 2 x Horizontal beater. 37 & 38

4.9 3 x Horizontal beater. 39 & 40

4.10 Transverse drive assembly horizontal beaters. 41 & 42

4.11 Transeverse gearbox horizontal beaters. 43 & 44

5. P.T.O AND TRANSMISSION

5.1 MK4 Transmission model 75. 45 & 46

5.2 MK4 Transmission model 90/105/120. 47 & 48

5.3 MK4 Transmission model 150. 49 & 50

5.4 Walterscheid P.T.O shaft. 51 & 52

5.5 Walterscheid wide angle PTO shaft. 53 & 54

5.6 Problems and possible solutions. 55 & 56

5.7 Comer series V PTO shaft assembly. 57 & 58

5.8 Comer wide angle guard complete. 59 & 60

5.9 Comer T60 underbody driveshaft. 61 & 62

5.10 Comer plastic guard assembly. 63 & 64

5.11 Comer guard safety chain fixing. 65 & 66

6. BRAKE & AXLE ARRANGEMENTS

6.1 MK4 brake arrangment 120/150/ widebody. 67 & 68

6.2 Brake parts MK4 75/90/105. 69 & 70

6.3 Axle hub and bearing parts MK4. 71 & 72

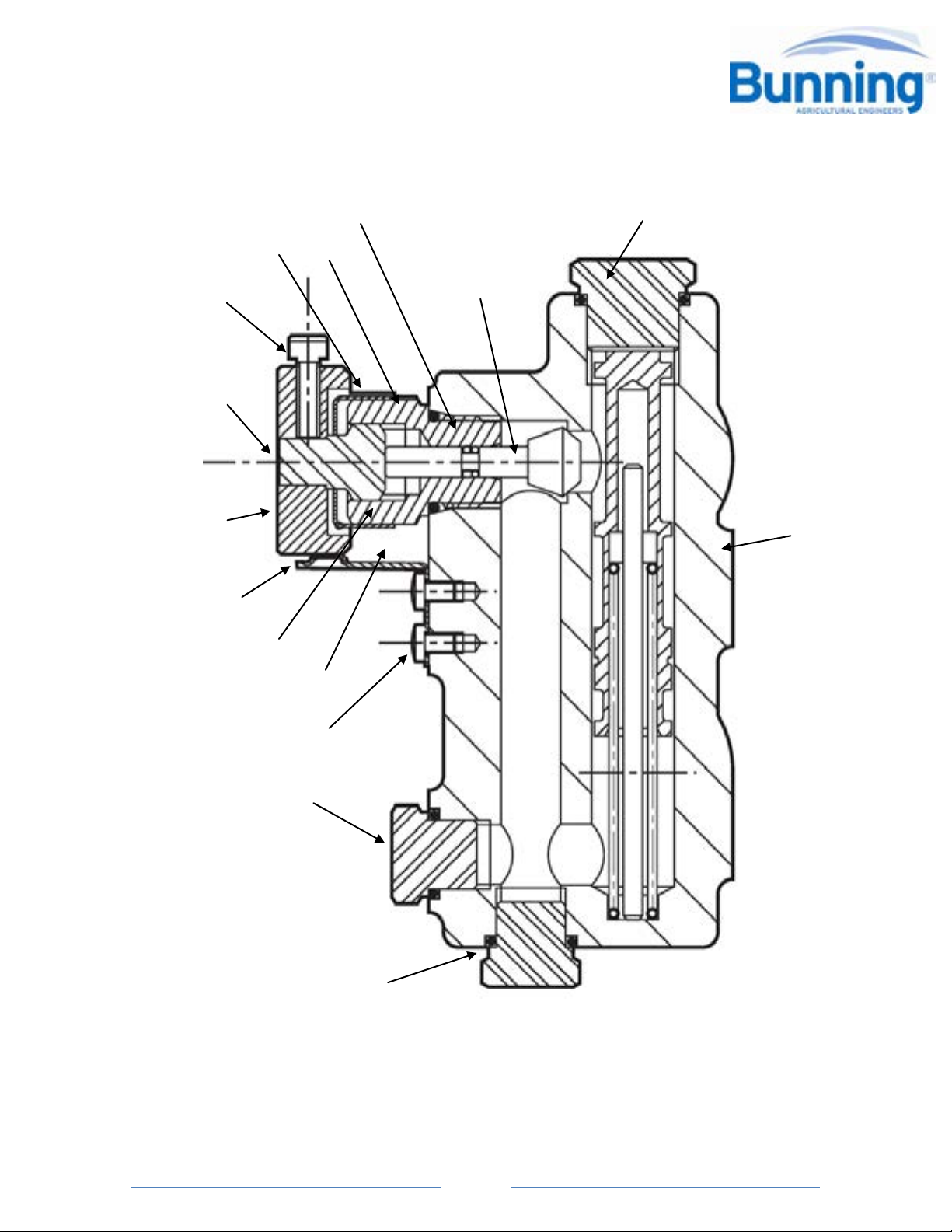

6.4 Hydraulic brake ram assembly 30mm bore MK4 75. 73 & 74

6.5 Hydraulic brake ram assembly 35mm bore. 75 & 76

MK4 90/105/120/150 and WB.

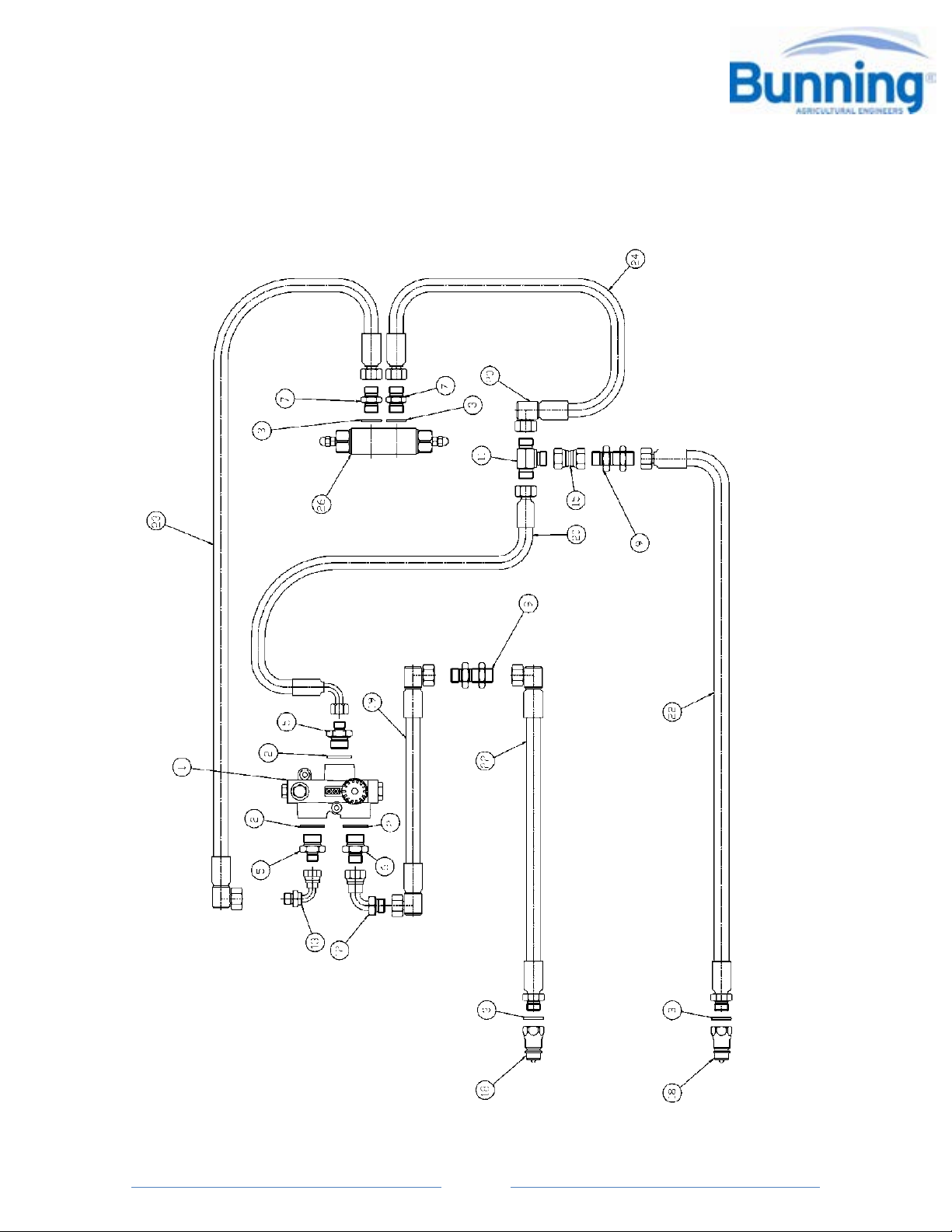

6.6 Hydraulic brake circuit –single axle. 77 & 78

6.7 Hydraulic brake circuit –rear drawbar clevis. 79 & 80

6.8 Hydraulic brake circuit - tandem axles. 81 & 82

7. AXLES & SPRUNG DRAWBAR

Safety notice. 83

General information. 84

Axle maintenance and adjustment. 85 to 96

Minimum program of maintenance sheet. 97

8. TYRES AND WHEELS

8.1 Tyre and wheel maintenance. 98

8.2 Tyre pressure settings. 99

8.3 Wheel type and torque settings. 100