222 W.Memorial Road, Oklahoma City, OK73114-2317

Phone: 1-800-624-7697 Fax: 405-755-8425

www.magpowr.com E-mail: magpowr@magpowr.com

INSTRUCTION MANUAL

MODEL PS-24

24 VDC POWER SUPPLY

All of the information herein is the exclusive proprietary property of Maxcess International, and is disclosed with the

understanding that it will be retained in confidence and will neither be duplicated nor copied in whole or in part nor

be used for any purpose other than for which disclosed.

Copyright 2004, all rights reserved.

Periodically there will be updates to this manual. The latest version is available at www.magpowr.com or by calling

1-800-MAGPOWR (624-7697).

1.0 Introduction

The MAGPOWR Model PS-24 is a controllable current regulator for 24 vdc magnetic particle clutches and brakes.

The PS-24 also provides a small amount of reverse current to maximize the torque range of the clutch / brake.

The PS-24 may be powered from either 24 vac or 24 vdc.

The Model PS-24 has three jumper selectable current ranges. Maximum outputs for the individual ranges are 0.5,

1.0 and 2.0 adc. The appropriate range is determined by the current rating of the clutch or brake to be controlled.

For best torque control resolution, the lowest current range providing sufficient current for maximum operating

torque should be selected. When using 24 vdc input power the maximum current output will be slightly less than

the selected range.

The PS-24 accepts either a remote adjustment potentiometer, or a 0 to 10 vdc analog control signal. An isolation

card is required when the PS-24 is connected to an external non-isolated control signal.

Connections are provided for an external 1 madc current meter. The meter display will indicate output current as a

percentage of the output range selected.

The control circuits are not electrically isolated from the power circuits. The control circuit negative is connected to

the P.E. connection, i.e., control input circuits are not floating.

2.0 Installation

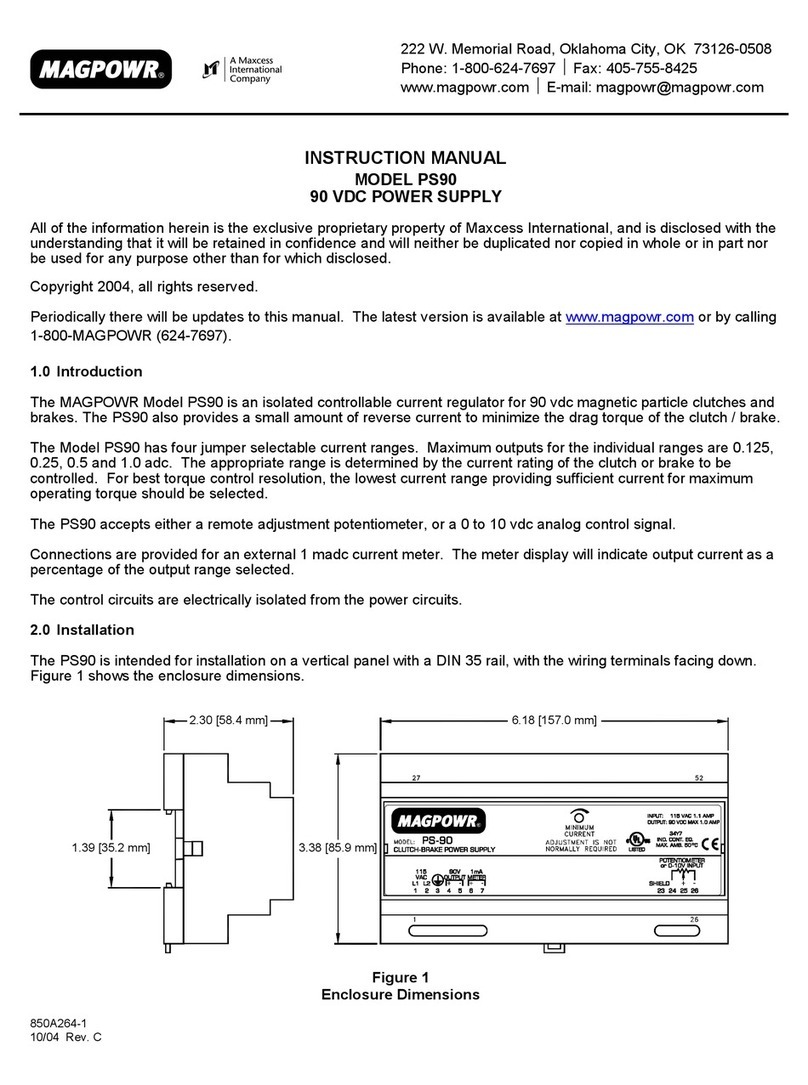

The PS-24 is intended for installation on a vertical panel with a DIN 35 rail, with the wiring terminals facing down.

Figure 1 shows the enclosure dimensions.

Wiring to and from the PS-24 must be done with double or reinforced insulation or protective screening which

provides protective separation. All wiring should comply with the essential requirements of the appropriate

standard(s) and is the responsibility of the installer.

850A302-1

06/05 REV. B