M A G U I R E P R O D U C T S , I N C .

5

M A G U I R E FLEXBUS™

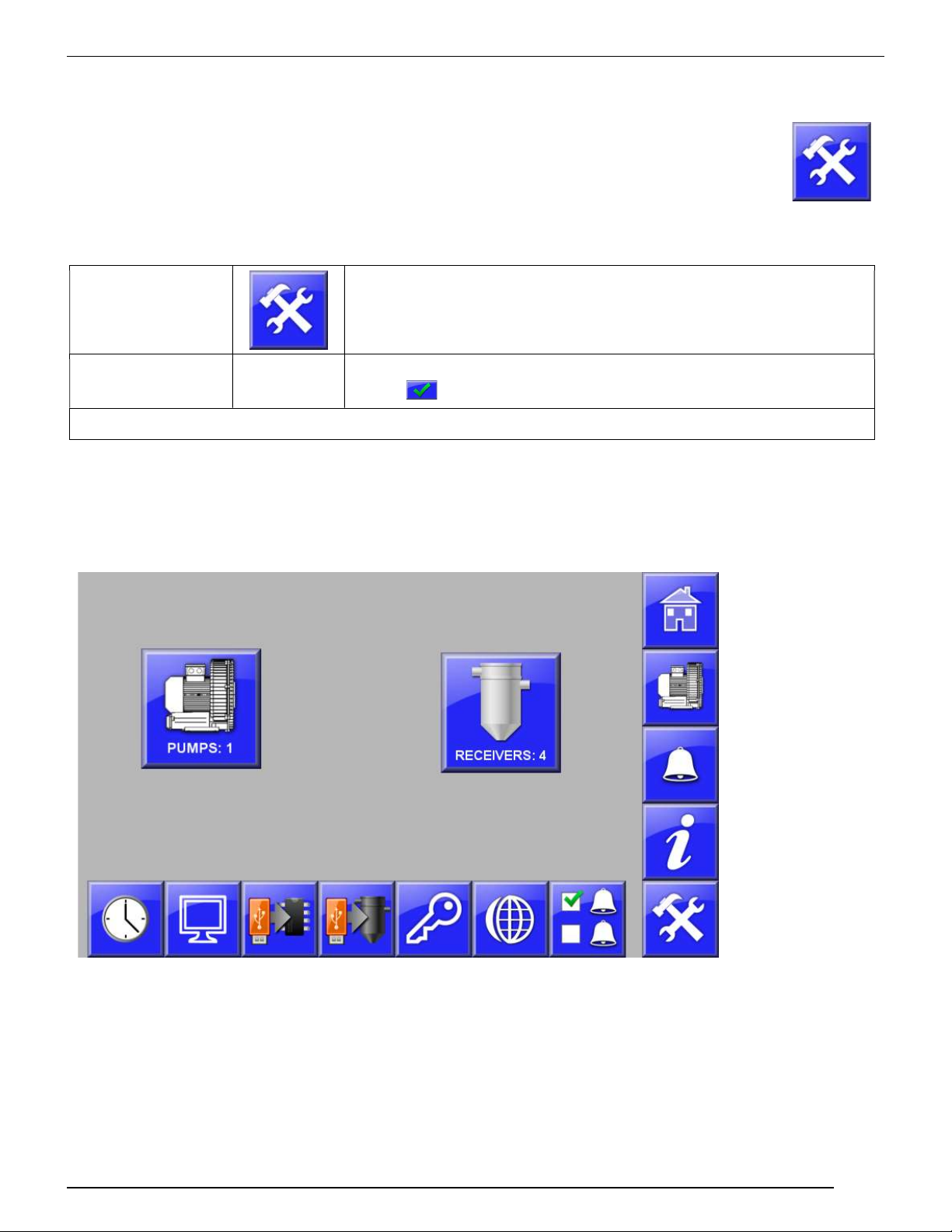

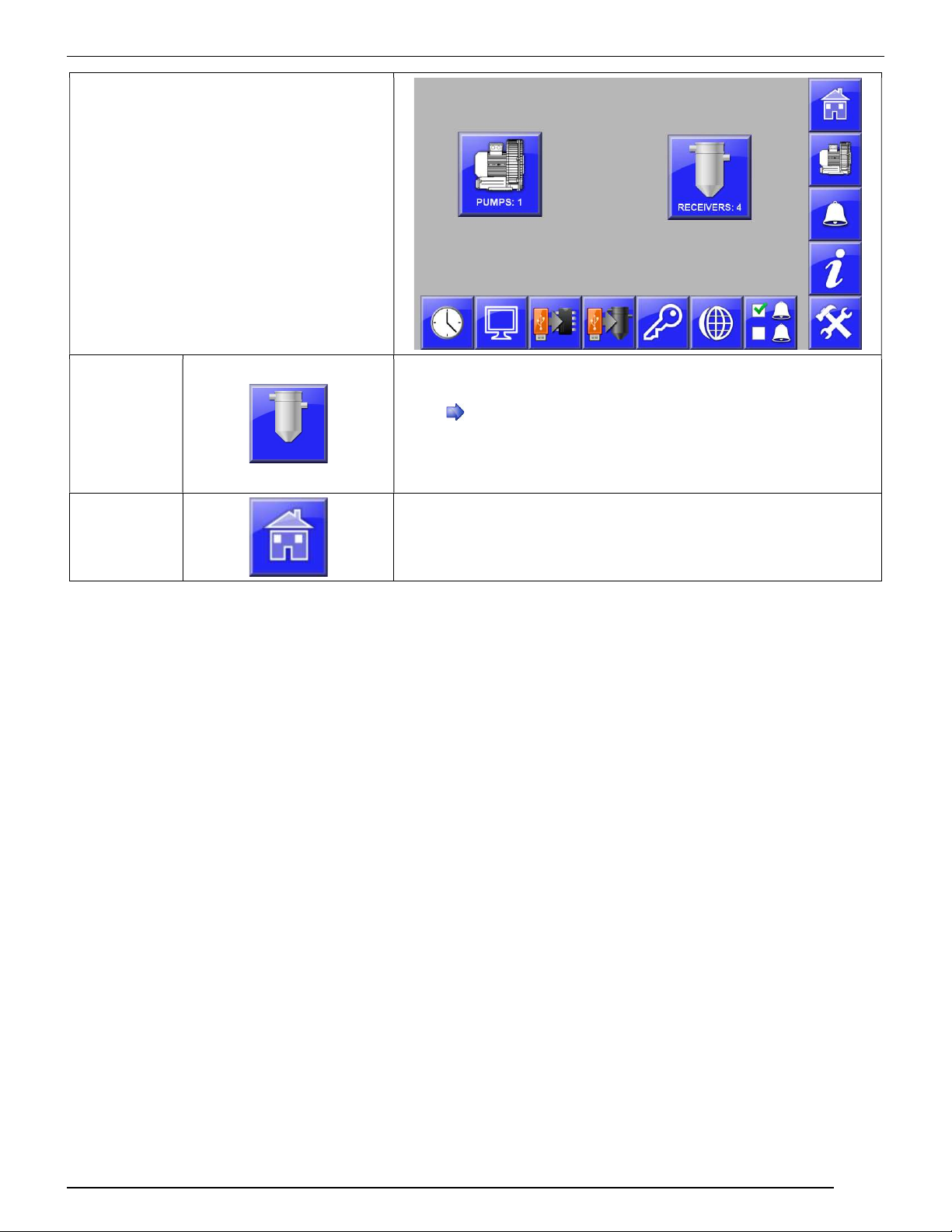

Flexbus / Flexbus Lite Overview

The Flexbus System allows you to avoid the guesswork associated with central system conveying.

Using one single, central Flexbus controller you can scale control up to five pumps and 120

receivers (24 per pump).

Flexbus Lite - Flexbus is also integrated into the Maguire 4088 Weigh Scale Touchscreen

Controller as Flexbus Lite for loading control of the individual blender.

This manual describes both the Flexbus Central Vacuum Loading System and the Flexbus Lite

Loading System integrated into the Maguire 4088 Weigh Scale Touchscreen Controller. The

Flexbus Central Loading System and the Flexbus Lite Loading System are very similar in setup

and operation. Differences in the systems will be noted throughout this manual when applicable.

Central Vacuum System Efficiency

Utilizing a 3-phase vacuum pump to supply multiple vacuum receivers is much more

efficient that using separate vacuum loaders.

Easy Installation

Install a single wire and conveniently located drops to connect the control to all receivers

and pumps.

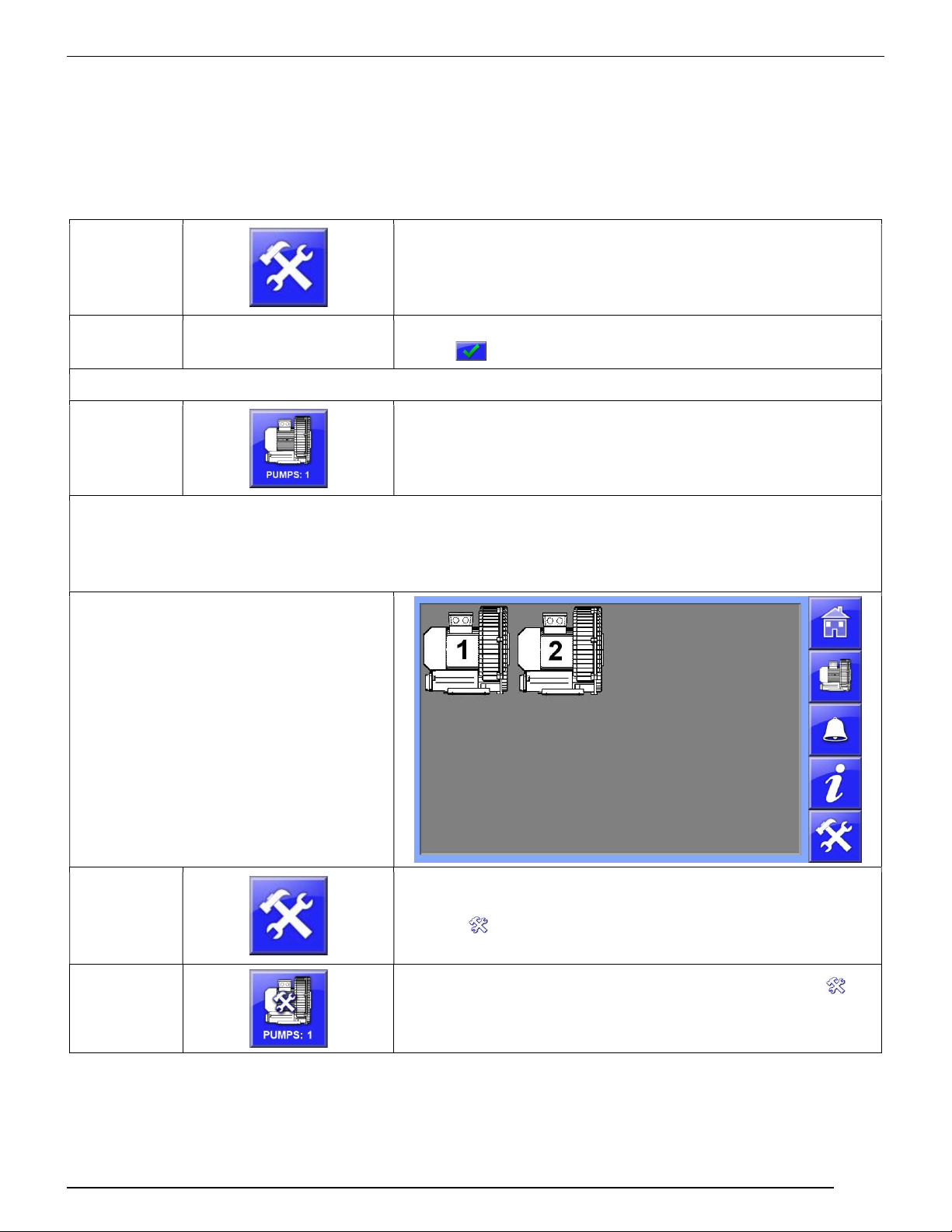

System Grows with Your Needs

Each Flexbus central control allows addition of up to 5 pumps and up to 24 receivers per

pump for a total of 120 receivers.

Flexbus Lite

Included within the Maguire Weigh Scale Blender Touchscreen, Flexbus Lite enables local

control of a single pump and up to 9 receivers.

Local Receiver Control

Provides ON/OFF and loading time convenience. No need to run back to the central

control.

Full Featured Central Control

Adjustable load, unload, priority, proportioning, purge, blowback and alarm settings.

Control over Communications

Flexbus provides communication support using Modbus TCP. See the Flexbus Modbus

register mapping document for more details.

Flexbus Loading Controller Features

7” Color Touch Screen

Control up to 5 pumps & 120 receivers (24 receivers per pump)

Auto ID of receivers for easy system expansion

Includes power supply and pump control board

Audible and Visual Alarms

Single wire CANbus connectivity

Adjustable load, unload, priority, proportioning, purge, blowback and alarm settings

24 VDC Control Voltage