M A G U I R E P R O D U C T S , I N C .

7

M P L M L S e r i e s V e n t u r i L o a d e r s

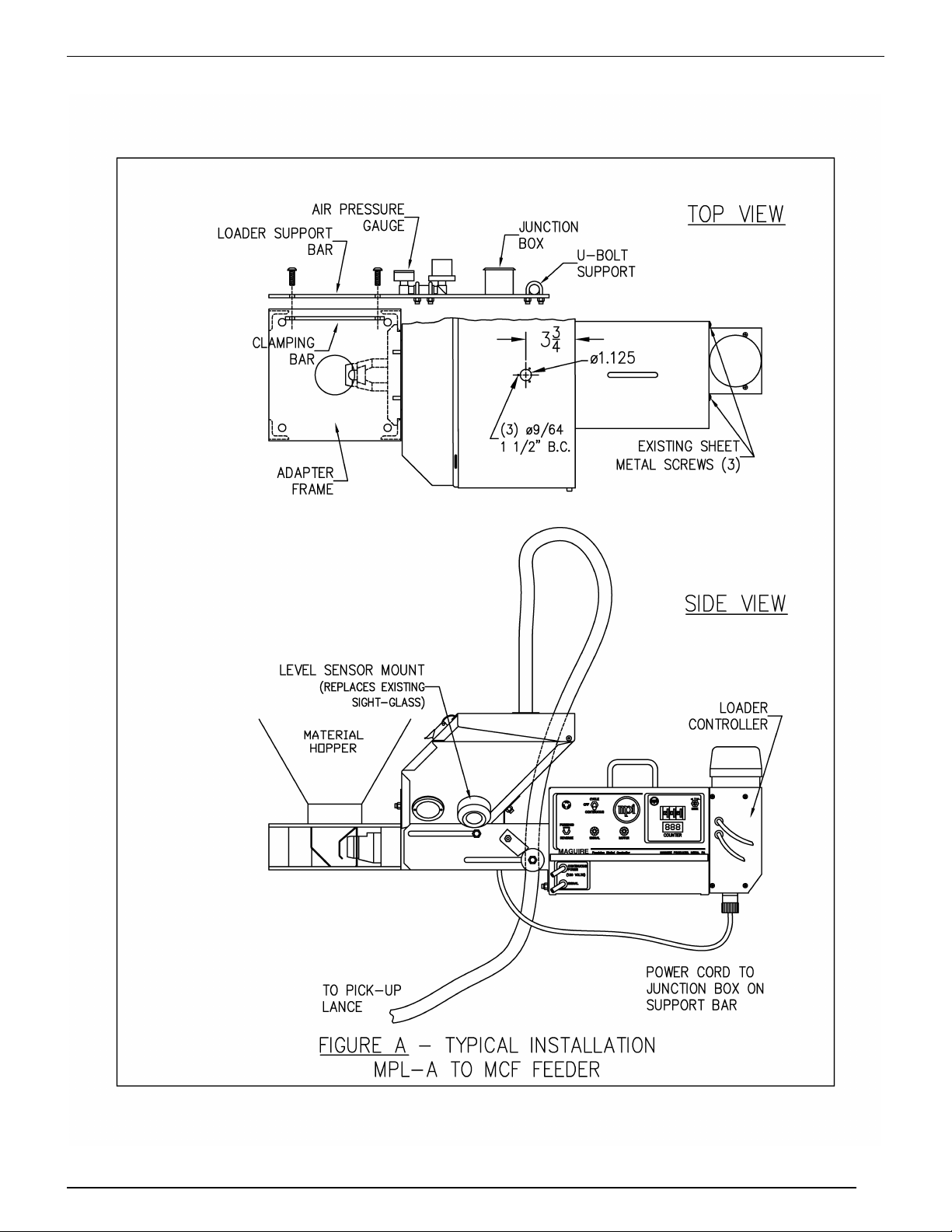

ASSEMBLY (Refer to diagrams)

MPL series:

1. Attach the Steel SUPPORT BAR to the ADAPTOR FRAME as shown in Figure A. To do

so, remove one bolt, slide clamping bar behind two corner angles; re-install bolt and

tighten. On a concentrate feeder, the bar attaches to the REAR of the adaptor frame and

extends BEHIND the controller.

All Models:

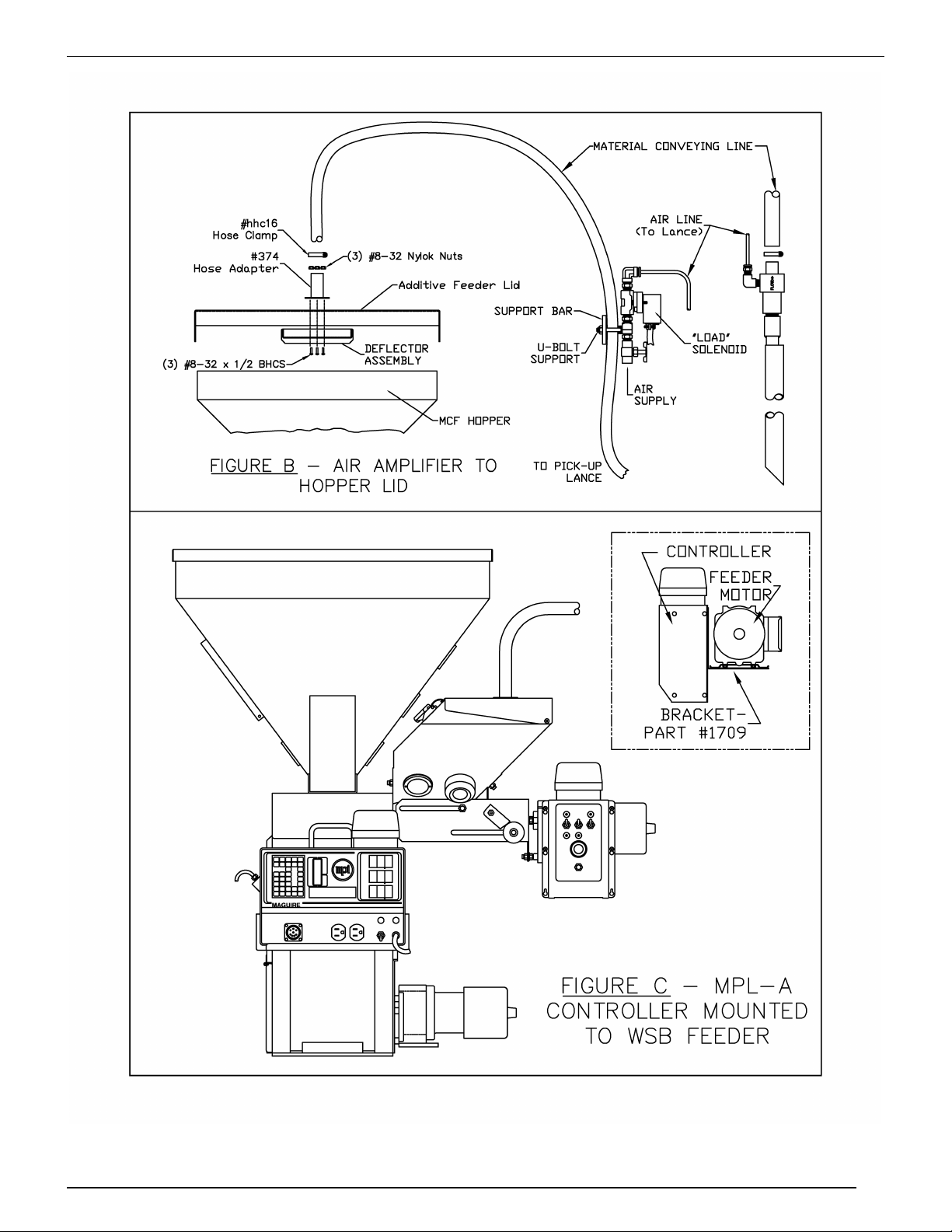

2. Mount the deflector and connection stub tube to the hopper lid as shown in Figure B.

NOTE: OLDER HOPPER LIDS:

If this unit is being added to an older hopper lid, you must first add the new hole

pattern to your existing hopper lid. The hole pattern is shown in Figure A.

NOTE: MICRO BLENDERS:

Replace the standard lid with the new lid provided.

3. Connect the red material suction hose to the top of the lid.

NOTE: MPL series models with SUPPORT BAR:

Secure this hose to the SUPPORT BAR using the "U" bolt provided. Adjust so

that there is NO STRAIN on the hopper lid.

4. Attach the other end of the red material hose to the venturi / pick-up lance provided.

5. Run the air line from the air solenoid to the venturi.

6. Install the SENSOR MOUNT into the hopper in place of one of the viewing windows. On

Concentrate feeder hoppers, with augers, remove the rear-most window on the operator

side (the same side as the controller front and nearest the controller). Use a 1/8" drill to

remove the window rivets. Install sensor mount using #6 sheet metal screws provided.

7. Install the gray (35 mm) level sensor into this mount. Secure with the rubber ring or by

tightening the hold down screw.

8. An air supply line of at least 80 PSI must be connected. A "quick disconnect" fitting is

recommended. Airflow requirement is about 16 CFM. A 3/8" I.D. supply line is adequate.

Lower pressures and smaller I.D. lines may, or may not be adequate.