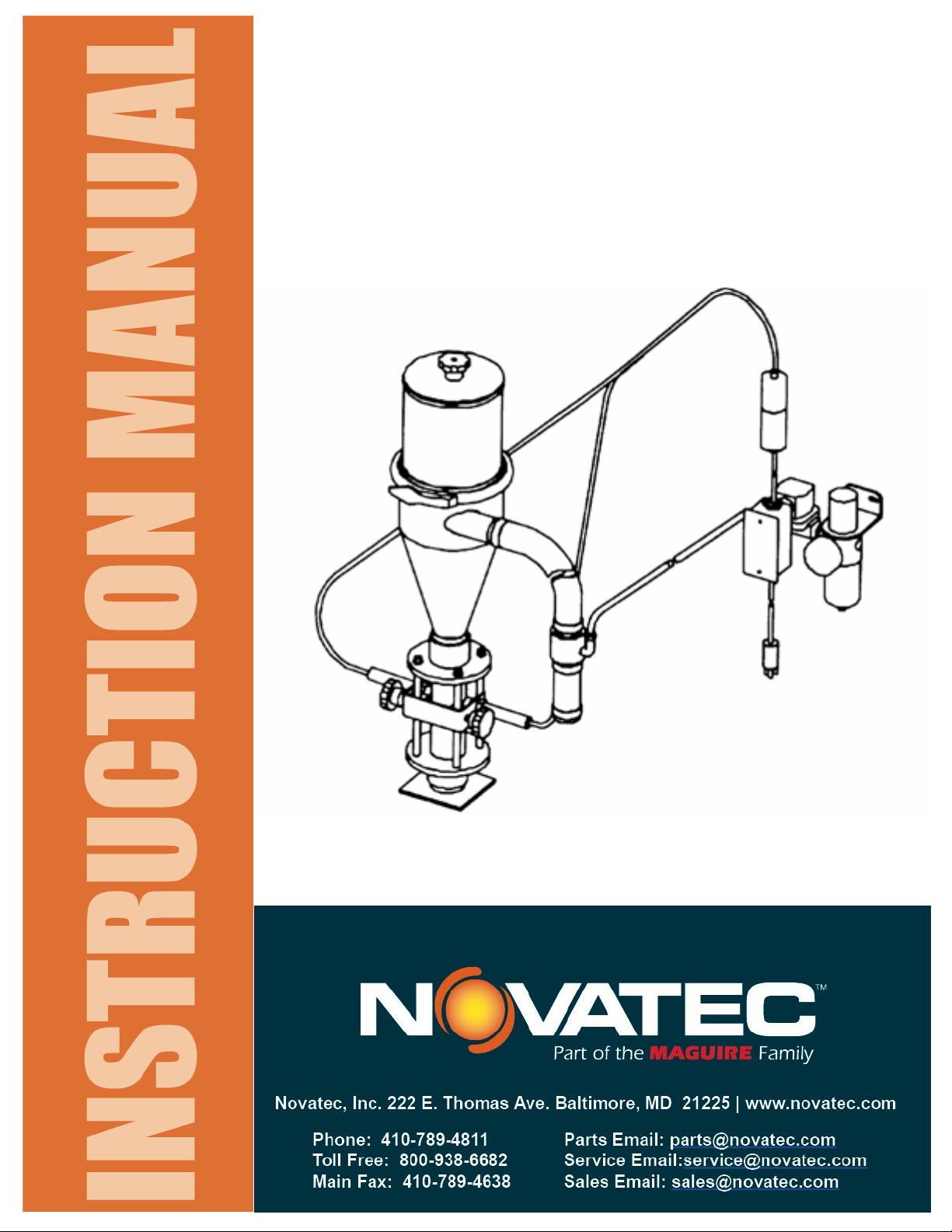

PRINCIPLE OF OPERATION

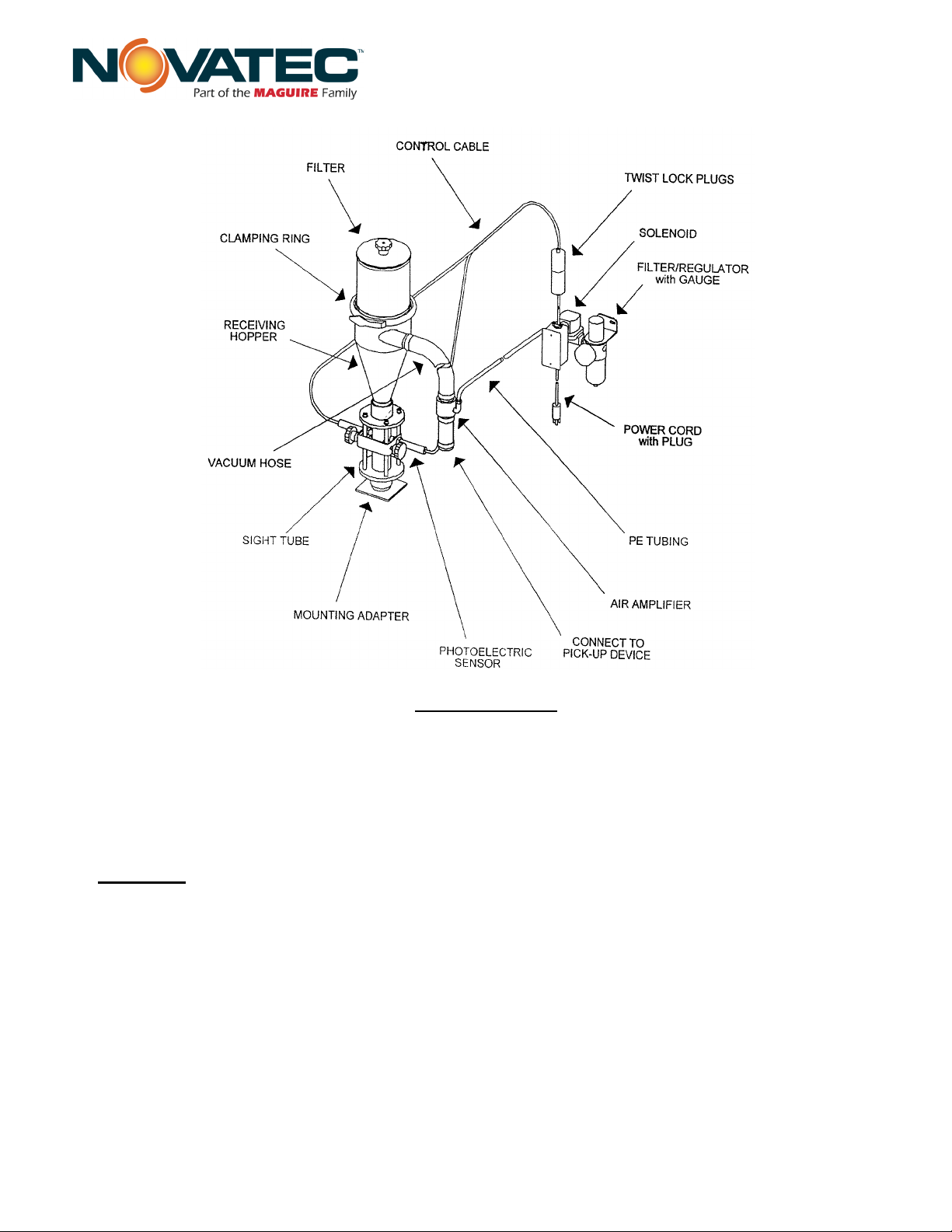

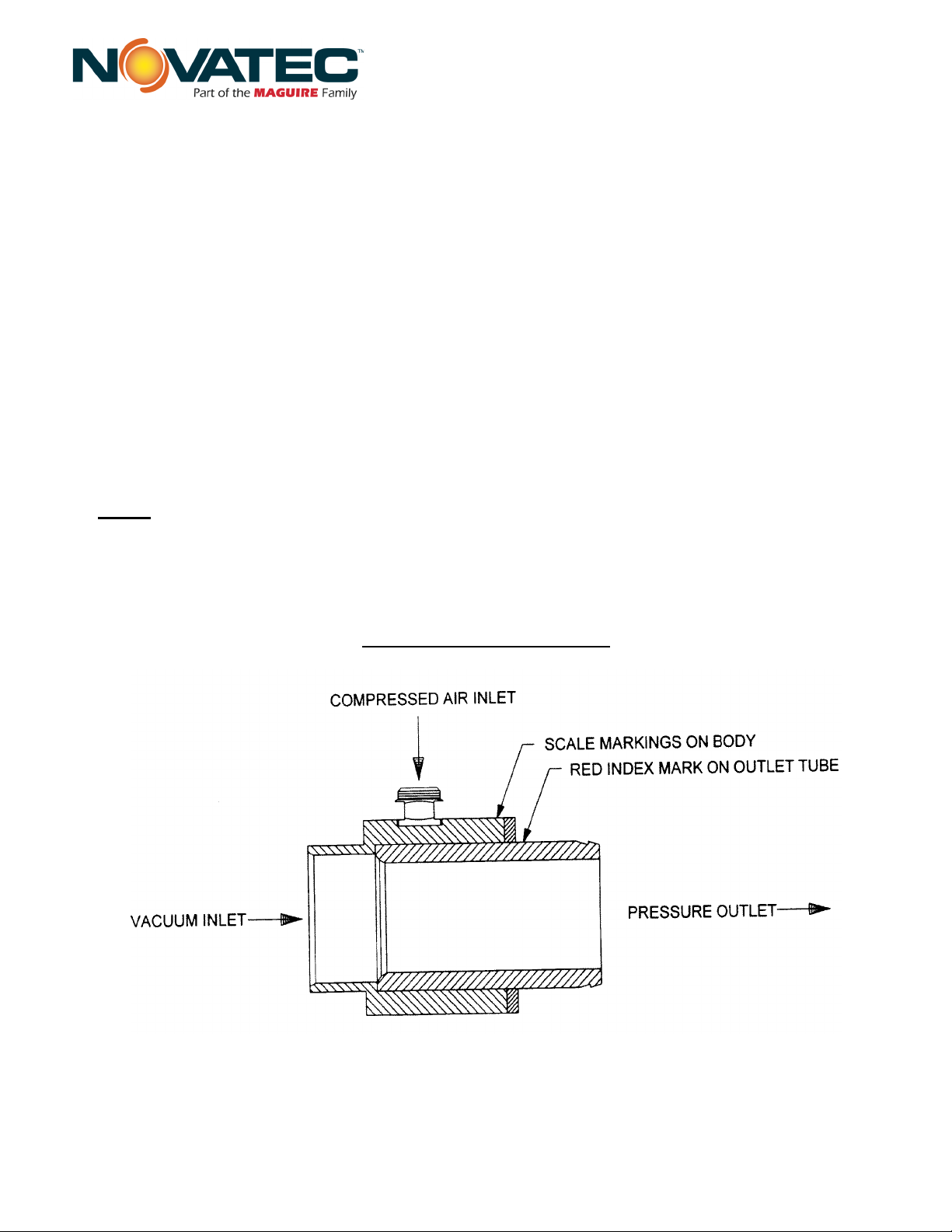

Novatec Model AL-1 loaders utilize compressed air in conjunction with an air amplifier to convey

material into a chamber. A small flow of compressed air passing through the amplifier creates a large

discharge flow by entraining the surrounding air. The machine or hopper mounted cyclone utilizes a

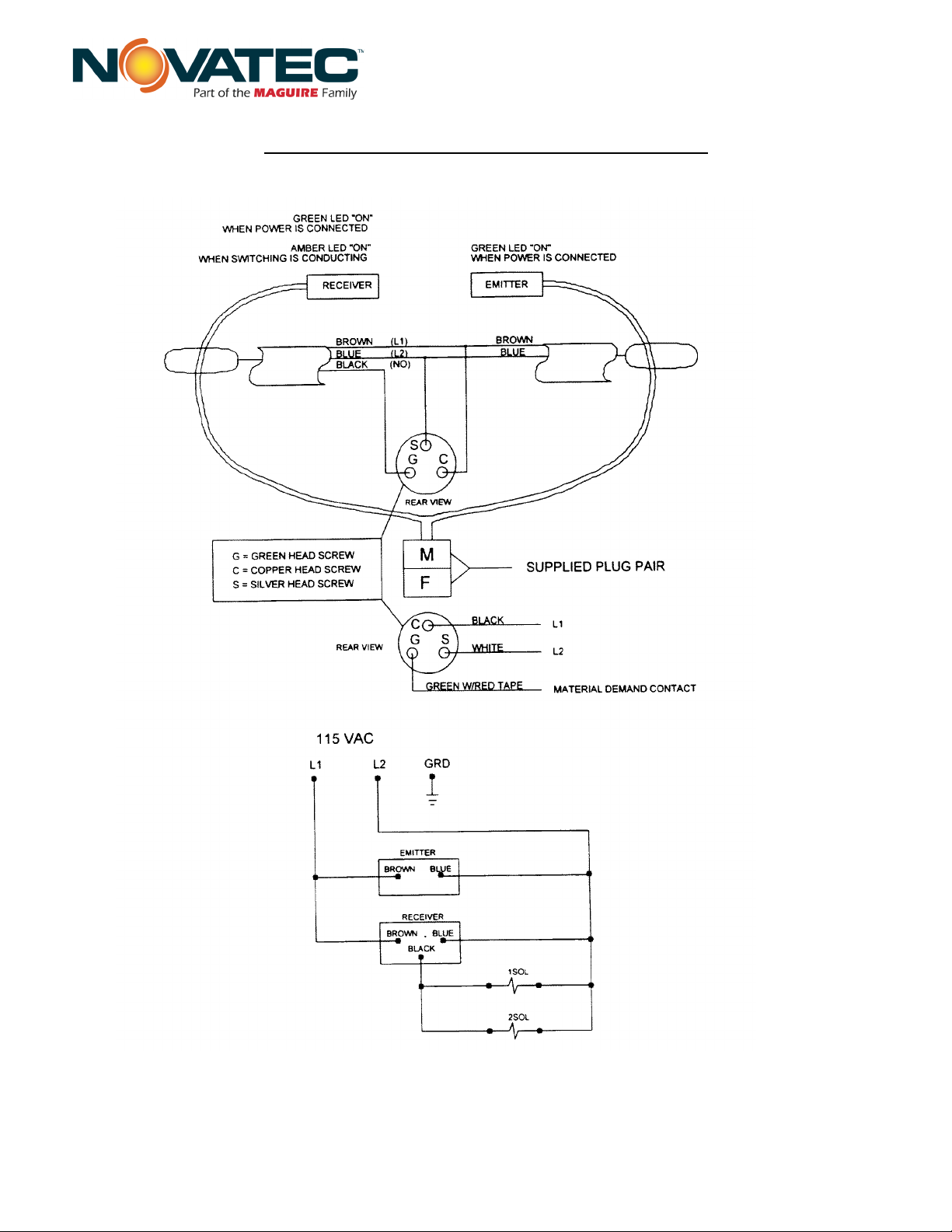

clear sight tube directly below it, and a photoelectric sensor consisting of an infrared light source and

an infrared sensor. See Figure 1 on next page for photoelectric sensor installation and configuration

details. The sensor controls loader on/off operation based upon the level of material within the sight

tube. Material is continuously drawn into the chamber as long as the dual photoelectric sensor

elements determine there is no material between them. The material level can be adjusted by sliding

the photoelectric sensor mount bracket up or down along the sight tube rods. Loading is discontinued

any time the material level within the sight tube reaches the sensor, and then is enabled again once the

material level drops. This process ensures a steady, consistent level of material.

The loading operation is generated by a solenoid valve, which operates in response to the photoelectric

sensor. When material is present in the sight tube, the sensor de-energizes the solenoid valve, which

shuts off the compressed air and stops loading. Once the material level has dropped, the sensor

energizes the solenoid, allowing the compressed air to flow through the air amplifier.

Unlike capacitance types of sensors, dust build-up on the sight tube does not typically effect the

operation of the photoelectric sensor. The infrared beam of light will still pass through a layer of dust.

There are no sensitivity adjustments to be made to the sensor.

UNPACKING & INSPECTION

Caution should be exercised to see that the equipment is not handled roughly. The packaging must be

removed carefully. The equipment must not be used to pry against when removing the packaging.

Equipment is sent as completely assembled as possible so that there is little or no further attention

required prior to installation.

Once unpacked, visually inspect units for missing parts or damage received during shipment. All

electrical and mechanical connections should be checked for tightness, as vibration during transit may

cause them to loosen.