THE PASSION PEOPLE

www.magura.com 3

1. Welcome to the Passion People!

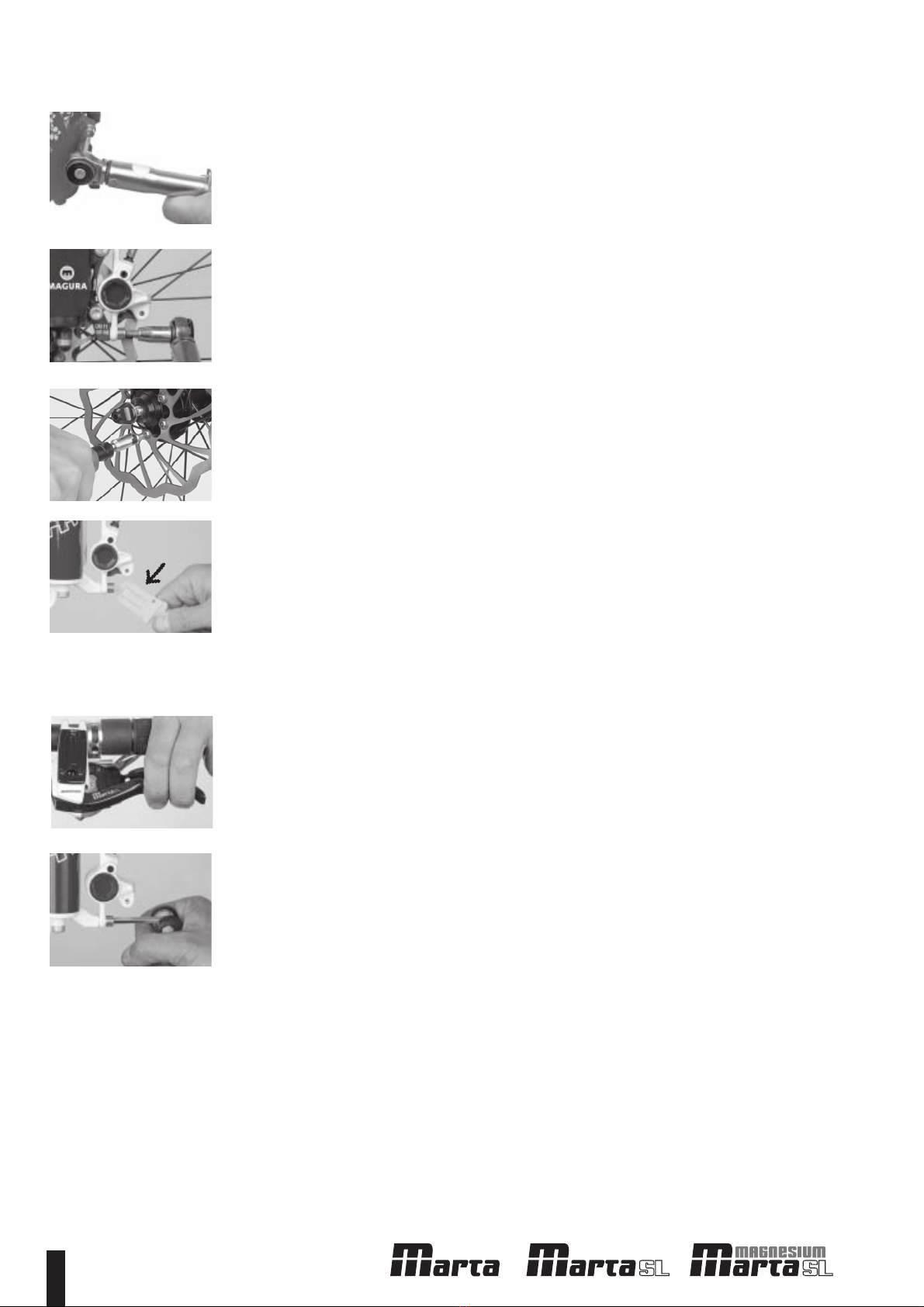

On the fully hydraulic MAGURA disc brake system Marta, Marta SL and Marta SL

Magnesium the braking force is transmitted to the braking surface by a mineral oil column.

The movement of the lever blade moves a piston, which is integrated in the brake lever

(master cylinder). The piston pushes the mineral oil column through the brake hose in the

direction of the brake caliper, where two pistons, on which the brake pads are fixed, are

pushed out. The friction between the brake pads and the rotor slowes down the bicycle and

causes both the rotor and the brake caliper to heat up.

Never touch either the rotor or the brake caliper after long braking as this may

cause serious burns

You will be pleased to find out that the MAGURA Marta disc brake offers a superior

braking power even with little hand force applied, no matter what the weather conditions

should be. Particularly in wet weather conditions disc brakes are much more responsive

than rim brakes and transmit their enormous power immediately after activating the brake

lever.

Disc brakes don’t wear your rims down. However if they have been mounted incorrectly

they might cause a squealing noise during braking, mainly during wet weather conditions.

This manual contains important information about the safe installation,

operation and maintenance of your MAGURA disc brake. We urge you to read

it carefully, become familiar with its contents and follow our recommendations to

help make your new braking experience enjoyable and trouble free.

All steps will be explained on the Marta model. The Marta SL and Marta

SL Magnesium are technically identical, with the exception of the carbon lever blades

(which are compatible with Marta).

Although the Marta disc brake system is relatively simple you should not ove-

restimate your technical skills! We therefore advise you to leave the following opera-

tions to a trained technician of a professional bike shop.

Should there be any further questions or problems we warmly recommend that

you visit our website www.magura.com where you will always find the newest and

hottest tips about all our products. On magura.com you can also dowload this manual in

a convenient A4 format and get online help around the clock for free. Stay tuned with the

Passion People!

Thank you for your confidence in our products, enjoy your ride and your new

MAGURA disc stoppers!

Happy trails!

Brake lever (master cylinder)

MAGURA Marta SL Magnesium

Brake caliper and rotor

MAGURA Marta SL Magnesium

Congratulations! You have purchased a

fully hydraulic MAGURA disc brake proudly

„Made in Germany“. You will be amazed

at he awesome braking power and the

minimum amount of maintenance that is

necessary on our stoppers. Good to know

that you are not alone, millions of riders

worldwide rely on them and every day our

numbers are increasing.