BA380701-en

Pos: 5 /-----Fo rmat-----/Inha ltsverzeichnis - 3Ebenen @ 5\mod_1168867441046_75.do cx @ 72920 @ @ 1

Safety ....................................................................................................................5

1.1 Introduction..............................................................................................................5

1.2 Symbols and Signal Words ......................................................................................5

1.2.1 Personal Injury..........................................................................................................5

1.2.2 Property Damage.....................................................................................................5

1.2.3 Information...............................................................................................................5

1.3 Intended Use ...........................................................................................................6

1.4 Requirements on Operating and Service Personnel ..................................................6

1.5 Safety Instructions....................................................................................................6

Description ............................................................................................................7

2.1 Requirements for the Place of Installation .................................................................7

2.2 Specifications...........................................................................................................7

2.3 Design .....................................................................................................................8

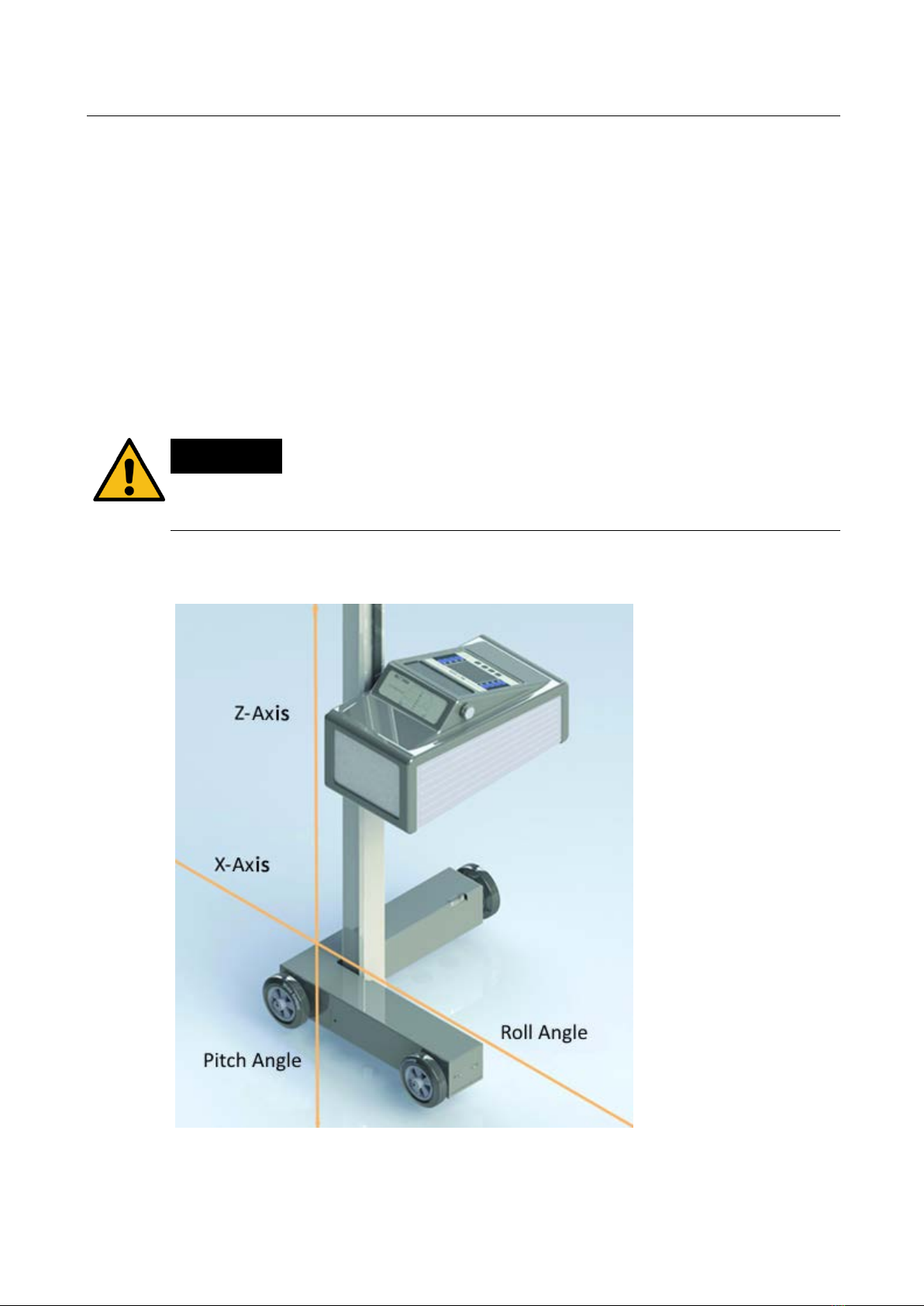

2.4 Electronic Levelling...................................................................................................9

2.4.1 Compensation Coordinate Axes of MLT 3000 ..........................................................9

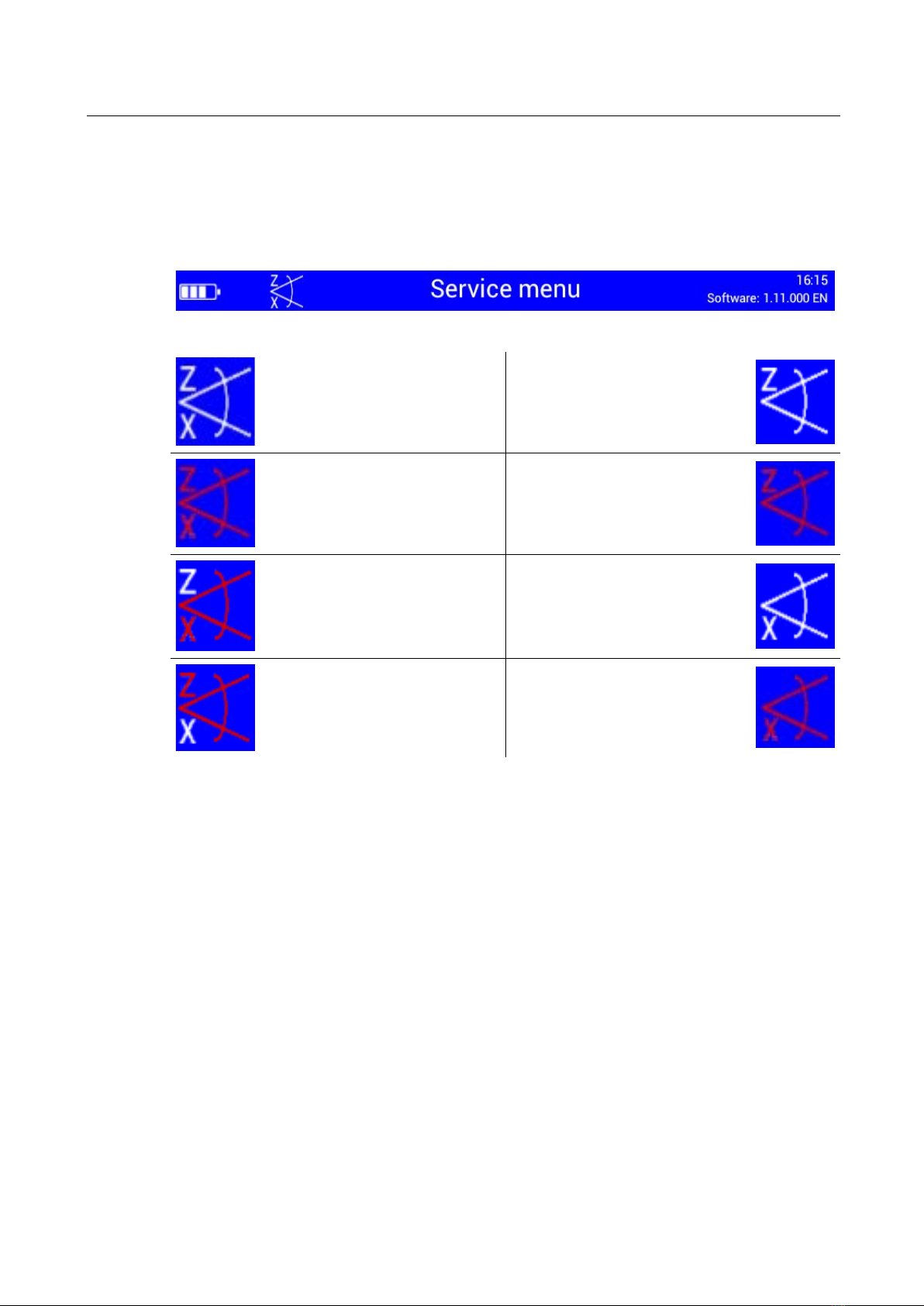

2.4.2 Angle Symbols .......................................................................................................10

2.5 Definition of Technical Terms..................................................................................11

2.5.1 Pitch Angle.............................................................................................................11

2.5.2 Low Beam .............................................................................................................11

2.5.3 High Beam.............................................................................................................12

Operation.............................................................................................................13

3.1 Switching On / Off..................................................................................................13

3.2 Aligning..................................................................................................................14

3.2.1 Laser Alignment Unit (Option) .................................................................................14

3.2.2 LED Adjustment Aid (Option) ..................................................................................15

3.3 Light Selection Buttons ..........................................................................................16

3.3.1 Headlight Test according to § 29 StVZO (Germany)................................................16

3.3.2 Showing the Button Labels ....................................................................................17

3.3.3 Adjusting the Pitch Angle........................................................................................17

3.3.4 Choosing the Vehicle Class ....................................................................................18

3.3.5 Browsing back through the Test Screens ...............................................................18

3.3.6 Choosing between Left-Hand or Right Hand Traffic................................................19

3.3.7 Manufacturer-Specific Test Instructions (OEM) .......................................................19

3.3.8 Navigating through the Test Levels.........................................................................21

3.4 Testing the Headlights............................................................................................22