7. Operation

mWARNING - This section discusses the appropriate and

safe methods for using the jack to raise and lower a

vehicle. Safe operation is not limited to simply raising and

lowering a vehicle - it also includes adequate preparation

before the vehicle is lifted. Failure to follow all of the steps

outlined in this section could result in serious injury or

death.

7.1 Raising a vehicle

1. Make sure the vehicle load does not exceed the rated

capacity of the jack (50,000 lbs. / 22,680 kg.)

2. Inspect the jack for signs of wear or damage (see

“Inspection Instructions” in Section 8). The jack should be

immediately removed from service if you detect any

abnormal conditions or signs of damage that suggest the

jack will not work properly or safely —When in doubt,

don’t use the jack!

mIf you see any signs of wear or damage, or if there is any

indication that the jack is not performing normally,

immediately take it out of service and contact customer

service at the address and number shown on the back

cover of this manual. NEVER use a jack that appears

damaged in any way.

3. Transport the jack to the work area by wheeling it. You

can push or pull the jack. Wheel the jack across smooth

surfaces only.

mJolting caused by the wheels catching on uneven

surfaces can cause physical strain and personal injury.

4. Select appropriate vehicle support stands and bring them

to the immediate work area. Follow the instructions

supplied with the vehicle stands. Use appropriate vehicle

stands to support the load immediately after lifting.

NEVER use the jack to support a load while working on a

vehicle. Failure to follow allof these instructions can result

in jack instability and loss of a load.

5. Examine the work area. Use the jack only on hard, level

surfaces capable of safely supporting the load. The jack

must ALWAYS remain in direct contact with the floor.

NEVER attempt to lift from a polished or greasy floor.

Clear the surrounding area of personnel, tools,

equipment, or any other objects that would interfere with

the use of the jack. If these conditions cannot be met,

move the vehicle and jack to an area where the lift can be

performed safely.

6. Chock the vehicle’s wheels. When raising a vehicle from

one end, always chock the wheels that will remain on the

ground. Make sure at least two wheels of the vehicle

remainincontact withthefloorat alltimes—NEVER use

the jack to raise all four wheels of the vehicle from the

floor.

7. Verify that the vehicle’s engine is not running before

raising it.

8. Identify a lift point on the vehicle that is capable of

supporting the load. Lift only on areas of the vehicle

specified by the vehicle manufacturer. The lift point must

be strong enough to sustain the lifting force without

damage to the vehicle.

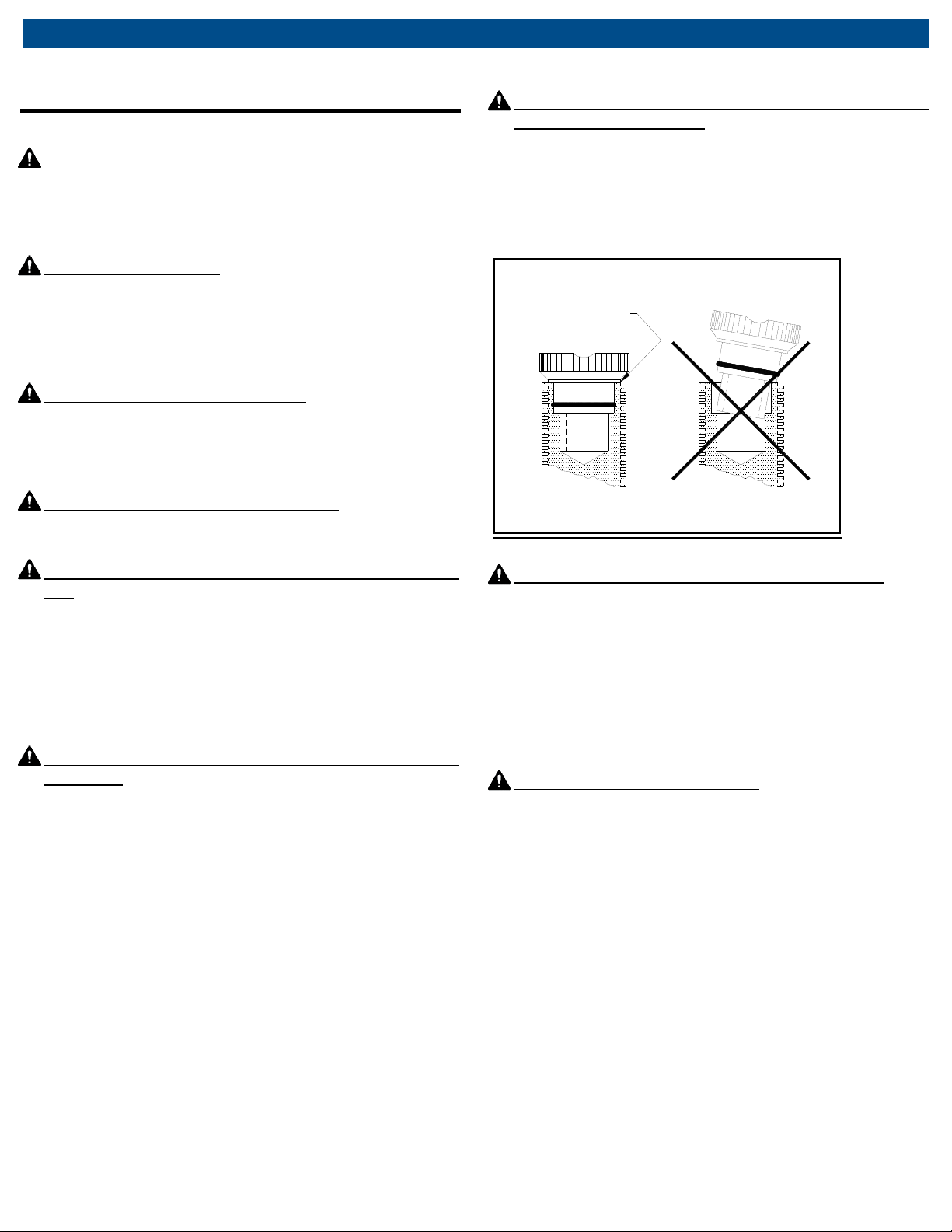

9. Position the lift pad for contact with the vehicle’s lift point.

Check to make sure the lift pad contacts and cradles the

lift point squarely and securely so as to prevent loss of

load.

10. Connect a quick coupler to the air control valve. Close

the release valve by rotating the release knob clockwise.

Attachairsupplyof 90psiminimumto200psimaximum.

The unit is now ready for use. Actuation of the air control

lever will now raise the lift pad. Rotating the release knob

counterclockwise will lower the lift pad (always rotate this

knob slowly and only rotate the knob as far as necessary

to lower the vehicle gently).

11. Raise the load to the desired height. Upon actuating the

air control valve, the jack lift pad will rise quickly until

contact is made with the load. Then the jack will continue

to lift the load (at a slower rate) until the air control valve

is released or the jack has reached the limit of its stroke.

12. Position appropriate support stands under the vehicle

manufacturer’s recommended lift areas to provide stable

support for the raised vehicle. Make sure all personnel

are clear of the area.

13. Lower the vehicle onto the support stands by slowly and

carefully turning the release control knob

counterclockwise. When lowering the jack, it is important

to keep the rate of lowering under control and to assure

the recommended vehicle lift points will properly rest on

the stand pad. Refer to the instructions and warnings

accompanying the support stands for additional

information about their safe use.

14. When the support stands are supporting the entire load,

the jack can be removed from the area before work on

the vehicle begins.