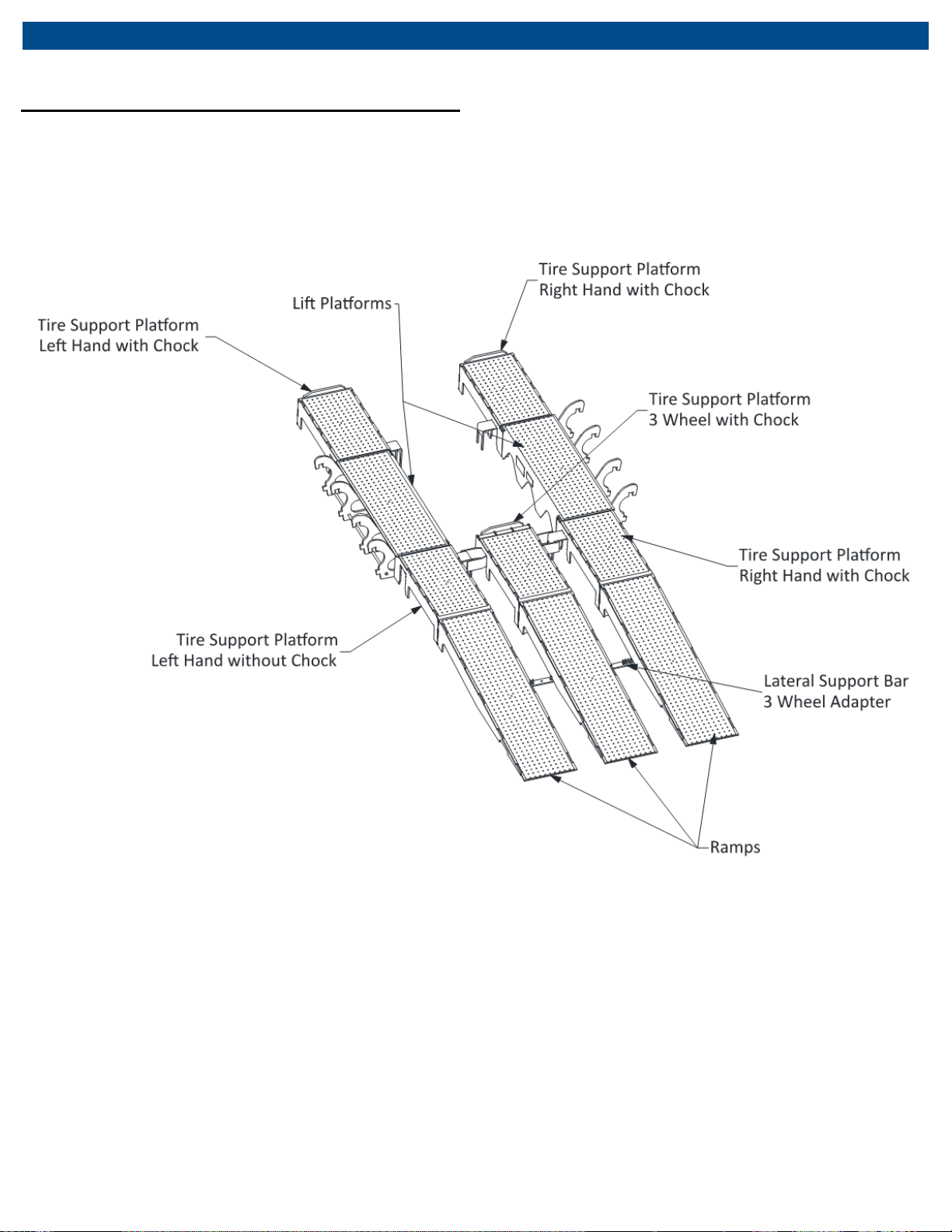

15. If the 3 wheel adapter is to be used, align the tabs

on the Lateral Support Bar with the ramps and

slide it back as far as possible. All three ramps

must be captured by the Lateral Support Bar.

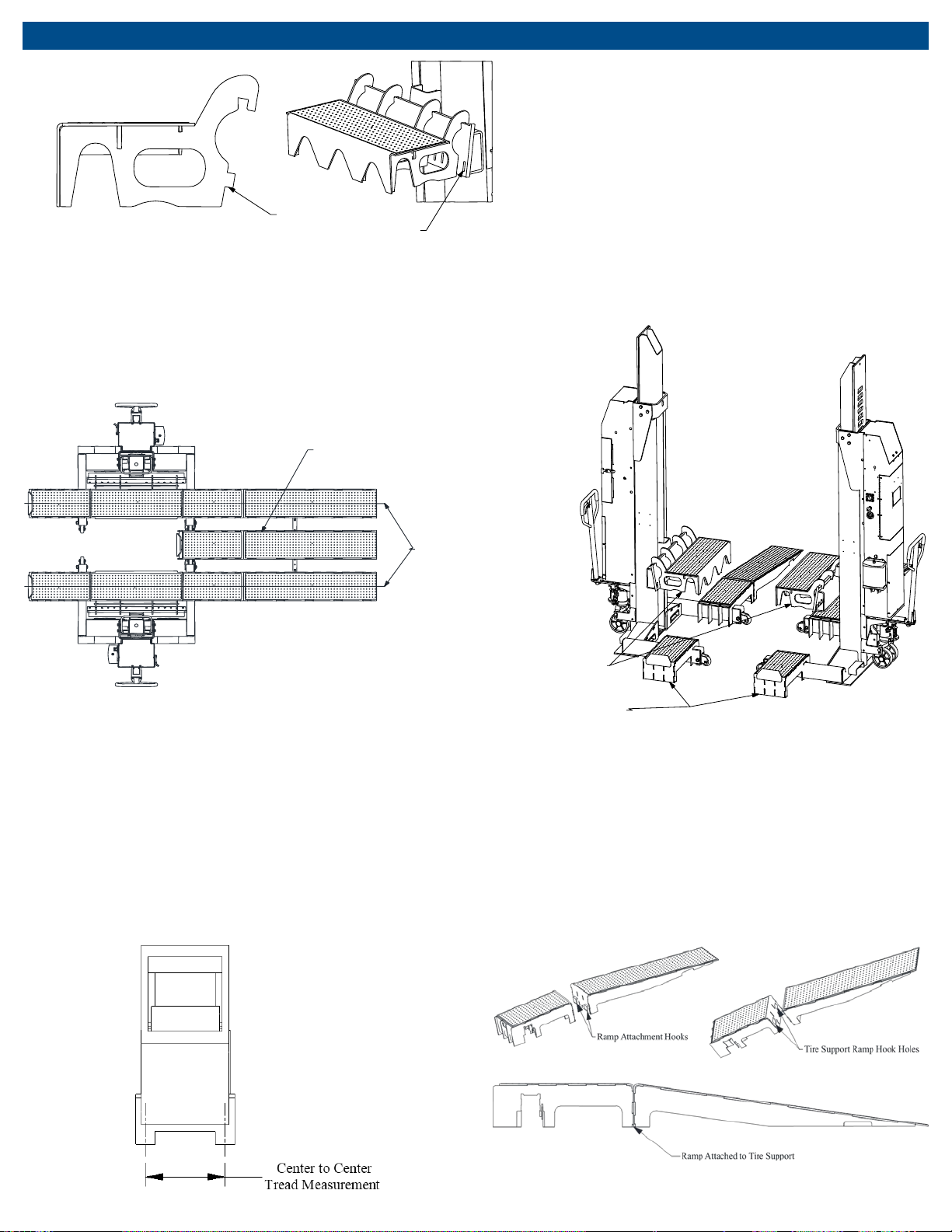

16. Lower the Lift Carriages completely and verify

correctalignmentofthe platforms.Backthe forklift

up the ramps only if using a 4 wheel forklift. If using

the optional 3 Wheel Adapter with a 3 wheel

forklift, pull onto the ramps forward. It is

necessary to have a spotter in order to keep the

forklift tirescenteredon the ramps andtire support

platforms. Position the forklift front to back so that

the center of gravity of the forklift is as close to

centered on the lift platforms as possible. The

center of gravity of the forklift must be within the

ends of the Lift Platform. Raise the forklift until the

tires are off the tire support platforms 2 inches.

Rock the forklift front to back to make sure it is

stable and can be lifted safely.

17. Once the check is made in step 17 above and the

forklift is stable, the forklift can be raised. Not

ensuring that the forklift is stable can result in loss

of load, which can result in personal injury and/or

property damage.

8. Structural Inspection

WARNING

Equipment must be removed from service and inspected

for damage immediately if subjected to an abnormal

shock or load. Failure to heed this warning may result in

personal injury and / or property damage.

WARNING

It is critical thateach piece ofthe adapter andeach liftunit

be inspected regularly for any signs of wear or damage

that might affect its ability to perform lifts safely. Any

equipment that appears to be damaged in any way, is

found to be badly worn, or operates abnormally must be

removed from service until necessary repairs are made.

Contact the manufacturer if you need to have equipment

serviced or if you have any questions about how to

address any wear or damage observedon the equipment.

The employer, owner, and/or manager are responsible for

maintaining the forklift adapter system and lift units in

good, serviceable condition. Employees must be trained

on how to inspect the equipment. Before each use of a

lift unit, the operator must visually inspect the lift unit for

any abnormal conditions. Any equipment subjected to an

abnormal load or shock must be immediately removed

from service and given a thorough inspection. The

employer, owner, and/or manager must inspect (or

appoint a knowledgeable personto inspect) all equipment

regularly. Regular inspections should be made weekly (if

the equipment is used daily) or monthly (if the equipment

is used only intermittently). Regular inspections should

include the following:

•Check for any visual cracks, chips or other signs

of excessive wear on all pieces of the adapter and

all lift units.

•Raise and lower the lift carriage of each lift unit

through its full range (up and down)—it should

move smoothly. If the lift stutters when lowering

(i.e., it moves in a jerky fashion) the slide pads may

need to be re-lubricated. Refer to the lift system

manual.

•Inspect the slide pad or roller contact surfaces for

damage, such as gouging, warping, etc.

•All controls should operate smoothly and freely.

Inspect the lift units for oil leaks. If oil leaks occur,

investigate and correct the source of the leakage

(refer to the lift system manual). WARNING! Clean up

any oil leakage immediately. Oil left on the floor can

create a slipping hazard.

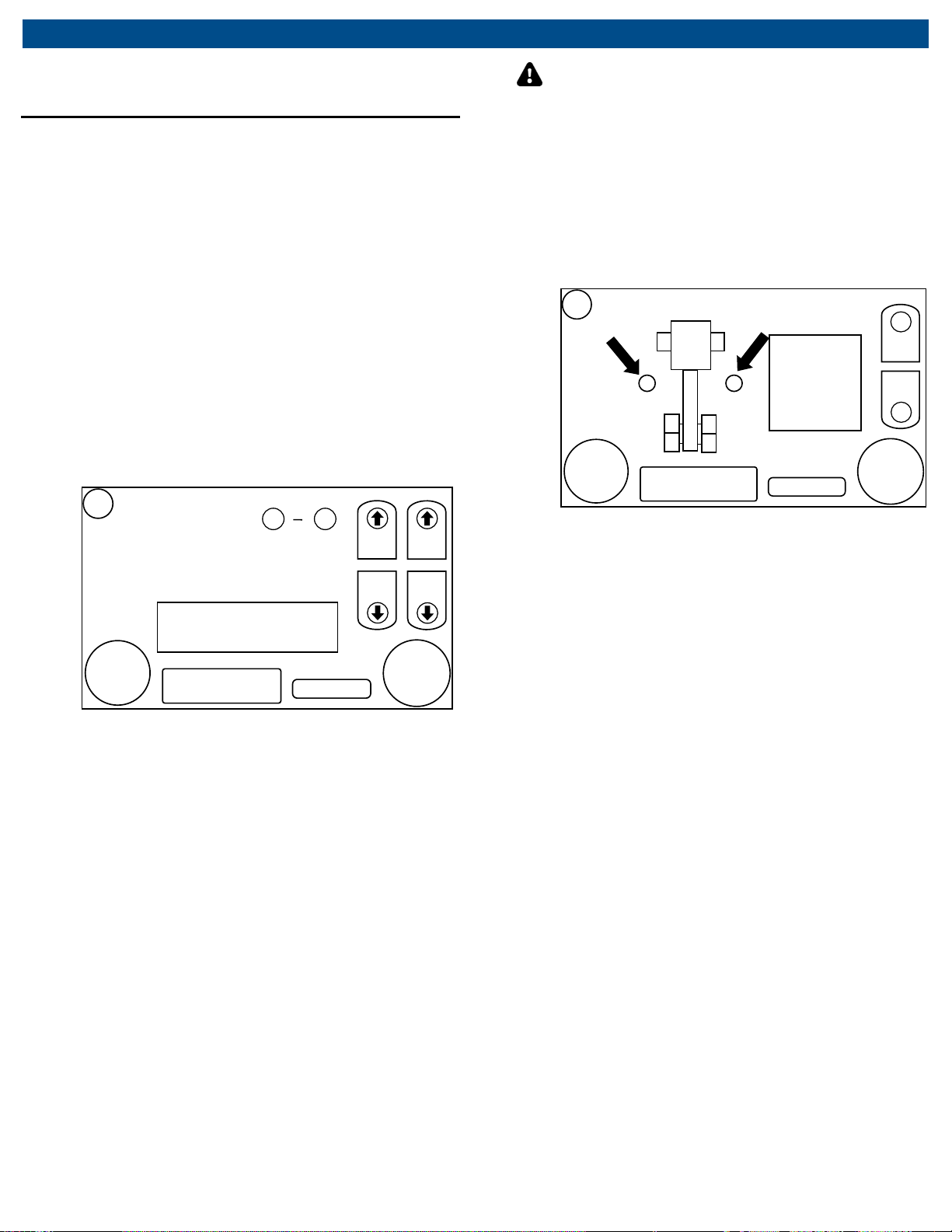

•Inspect the down stop catch pawl to make certain

it rotates forwardandbackwardfreely. If the catch

pawl does not move freely it may need to be

greased. Refer to the lift system manual.

•Check the positioning of the down stop catch

pawl. Refer to the lift system manual.

If you are not sure whether any identified wear or damage

is “serious”, DO NOT use the equipment. The time it takes

to determine whether or not the problem is “serious”or to

repair the problem is small compared to the time it will

take to deal with the consequences of a lost load (which

could include severe injury or death to personnel).

For more information about the lift units, refer to the

manual that was furnished with the lift units.