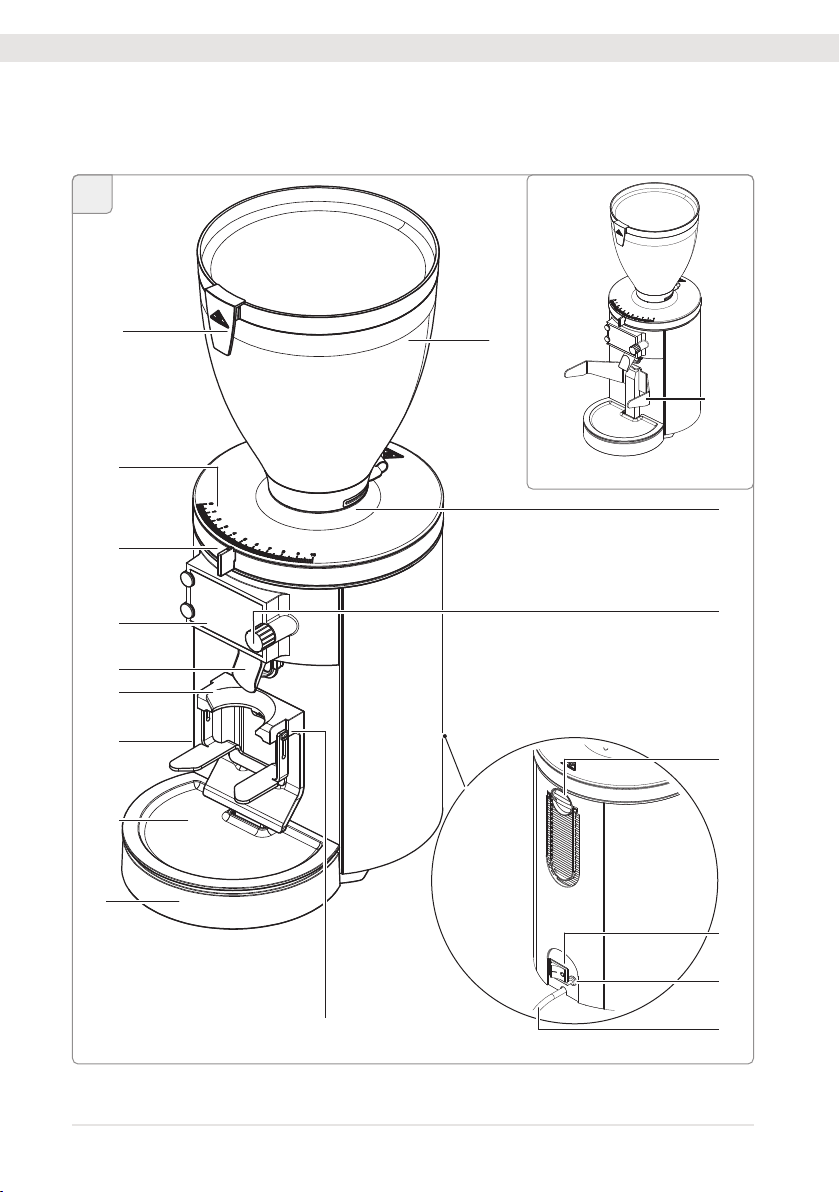

Scope of delivery

No. Designaon

1Bean hopper (with lid)

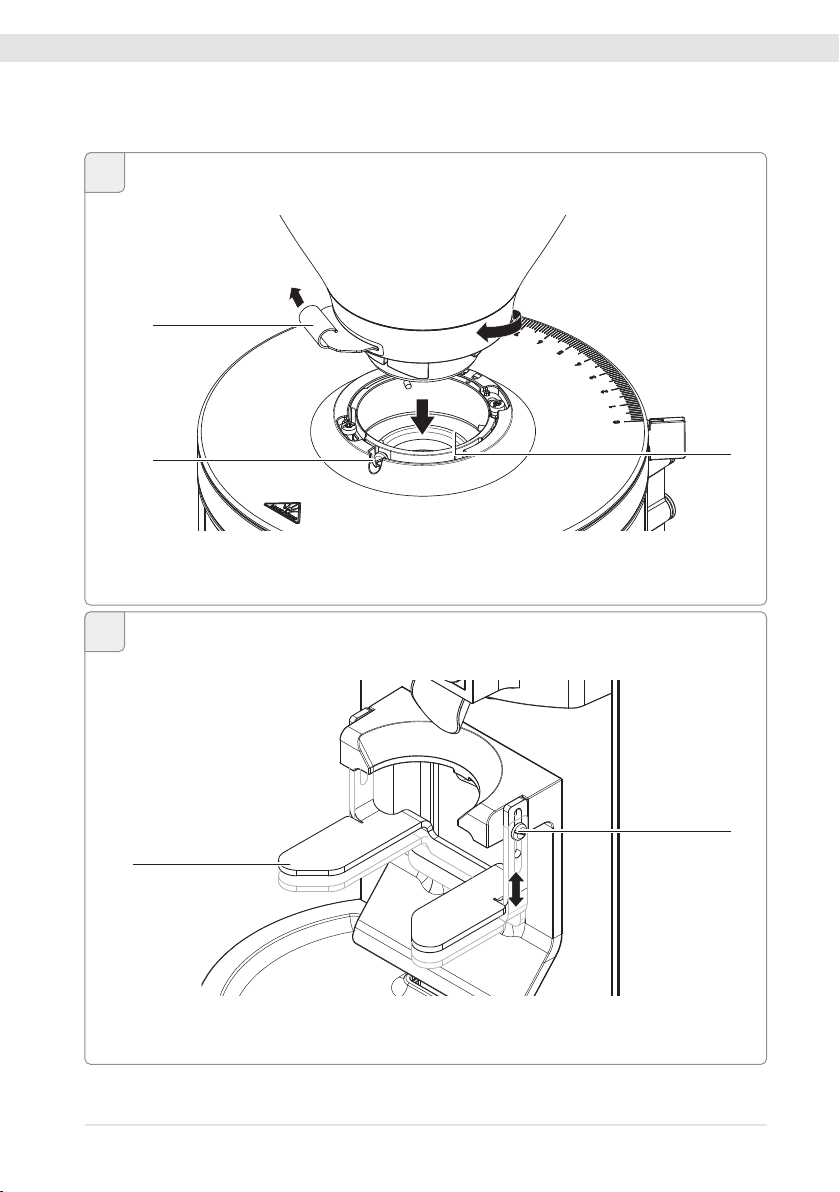

2Bean hopper intake

3Controller

4Grinding degree lock

5On/O switch

6Release buon (Thermal

overcurrent circuit-breaker)

7Power cable

8Screw for adjusting the

portafilter support

(left and right), 2×

9Load cell cover

10 Drip tray

11 Portalter support

12 Portalter intake/basket

holder

13 Spout

14 Display

15 Grinding degree slider

16 Grinding degree scale

17 Clip for the type of bean used

18 Sliding valve

19 Locking screw for the bean

container

20 Spout guide

21 Lower buon

22 Upper buon

23 Rescue buon

No. Designaon

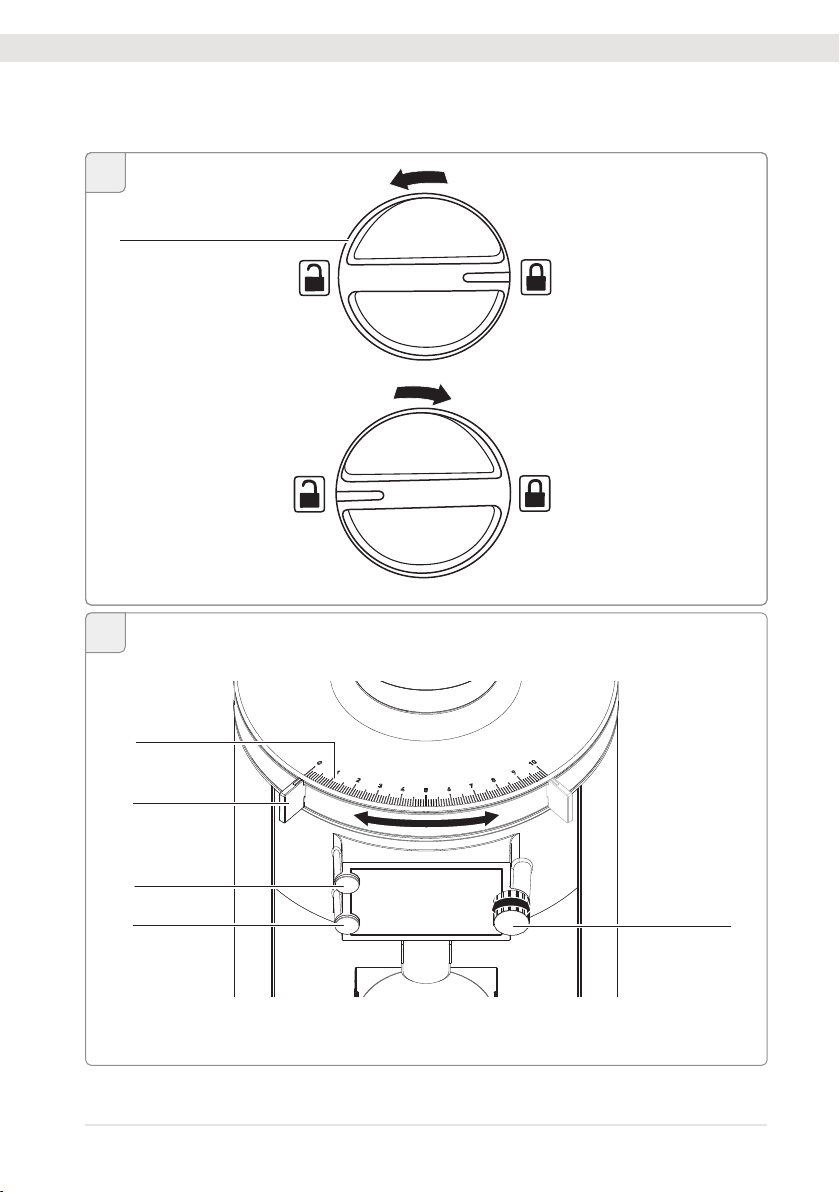

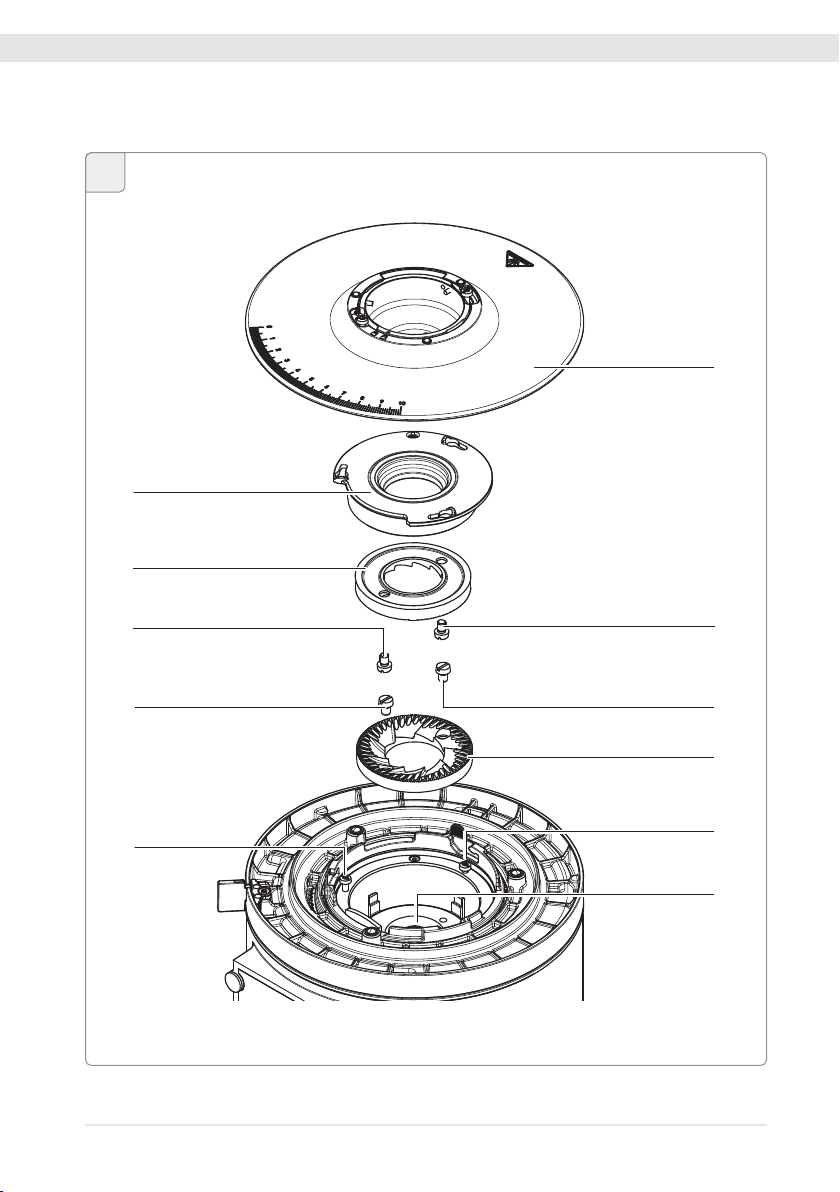

24 Locking screws for grinder lid

25 Lock/Unlock grinder lid

26 Grinder lid

27 Screws for xed grinding discs

28 Screws for rotang grinding

discs

29 Rotang grinding disc

30 Locking screws for xed disc

ange

31 Grinding disc carrier

32 Fixed grinding disc

33 Fixed disc ange

34 Flapper

35 Locking tool for grinding disc

change

36 Removal tool for grinding disc

change

37 Adjustment ring lock

38 Adjustment ring

39 Adjustment ring marker

40 Vernier scale

41 Zero adjustment of grinding

discs

42 Intermediate plate

43 Intermediate plate marker

E80 GbW |F80 GbW |ENESPRESSO GRINDER|FILTER COFFEE GRINDER

10