MAKE MENDEL Page 2

Technical Specification :

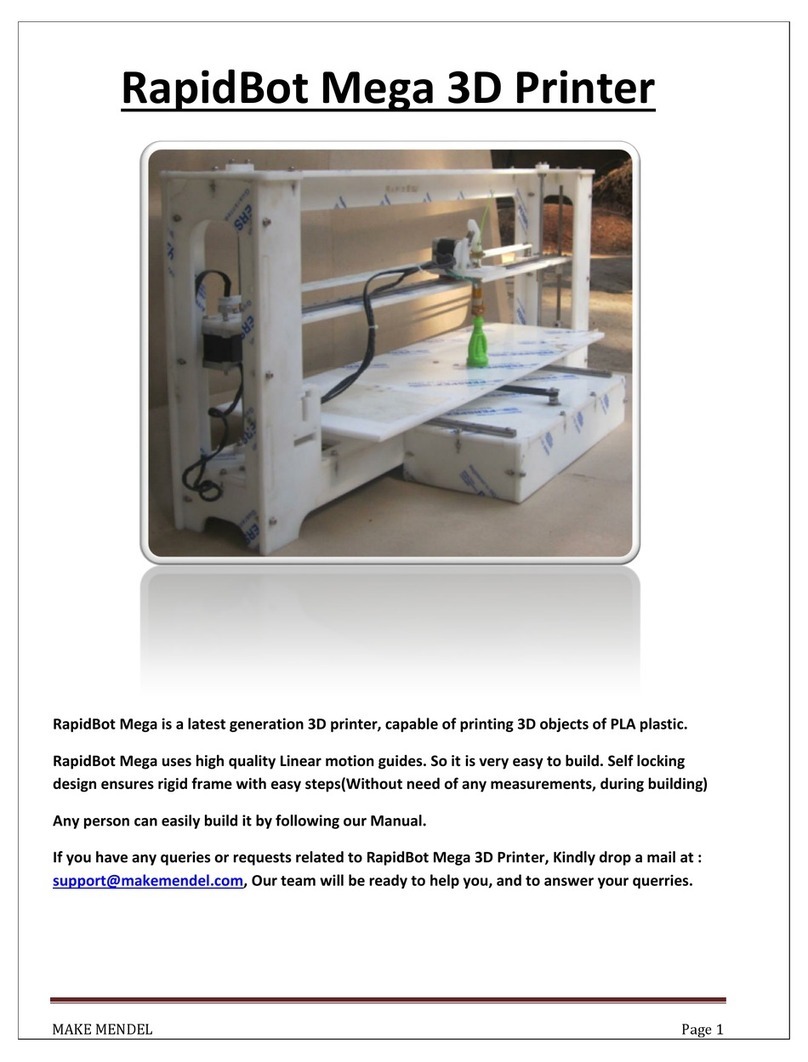

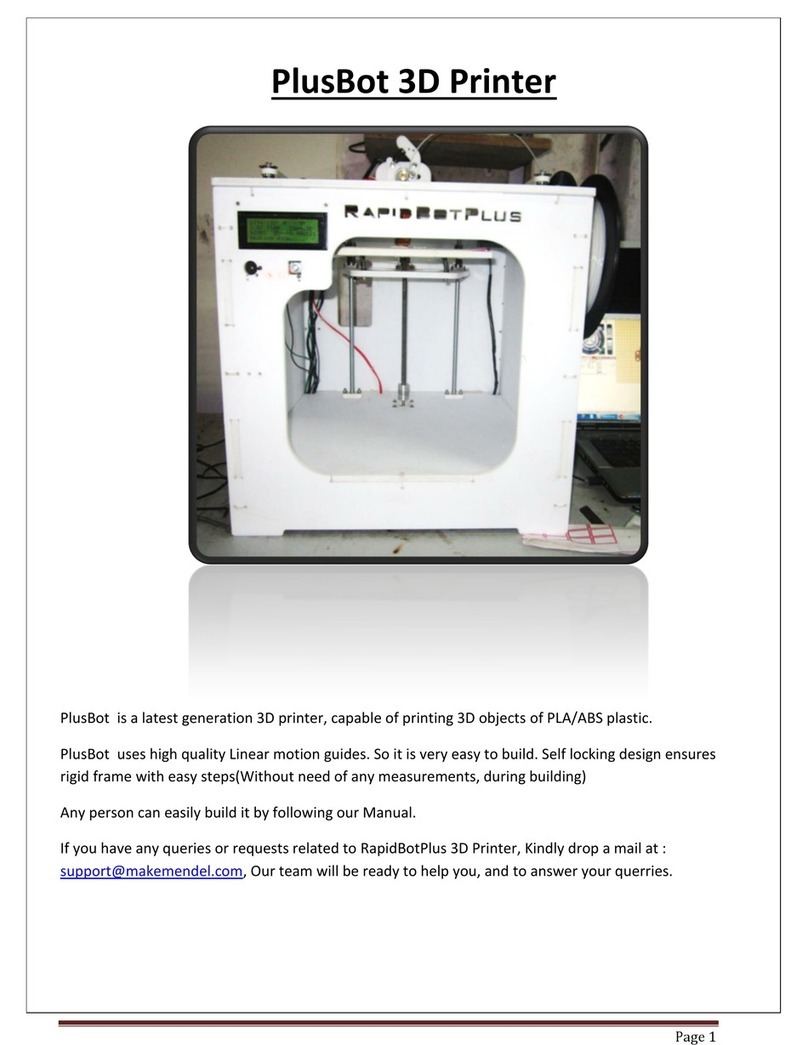

• Machine size 400 x 1000 x 400 mm

• Build size 220 x 740 x 165 mm

• Nozzle Diameter : 0.4mm

• Layer Thickness : 0.1mm

• Speed : 60 mm/s

• Positioning Precision : 27 microns

• Input Format : STL

• Software : Pronterface (Available on site for free under Download section)

•System Compatibility : Windows 7 and Vista

• Power Supply : ATX, 450W

• Weight (Kg) : 32

Features :

1) It uses high quality linear motion guides.

2) LCD Controller Support

3) Acme Lead screw with nut

4) Spring Printrbed Adjustment, which keep Printbed more stable.

5) Printrboard and Power Supply are adjusted at the bottom to give clean and neat look.

6) Very easy to build, just 8-10 hours.

7) High quality aluminium pulley with T2.5 belts for Accurate and easy belt placement.

8) Large build volume with easy accesibility.

9) Uses high quality acrylic from http://www.perspex.co.uk

10) Self locking design ensures rigid frame with easy steps(Without need of any

measurements, during building).