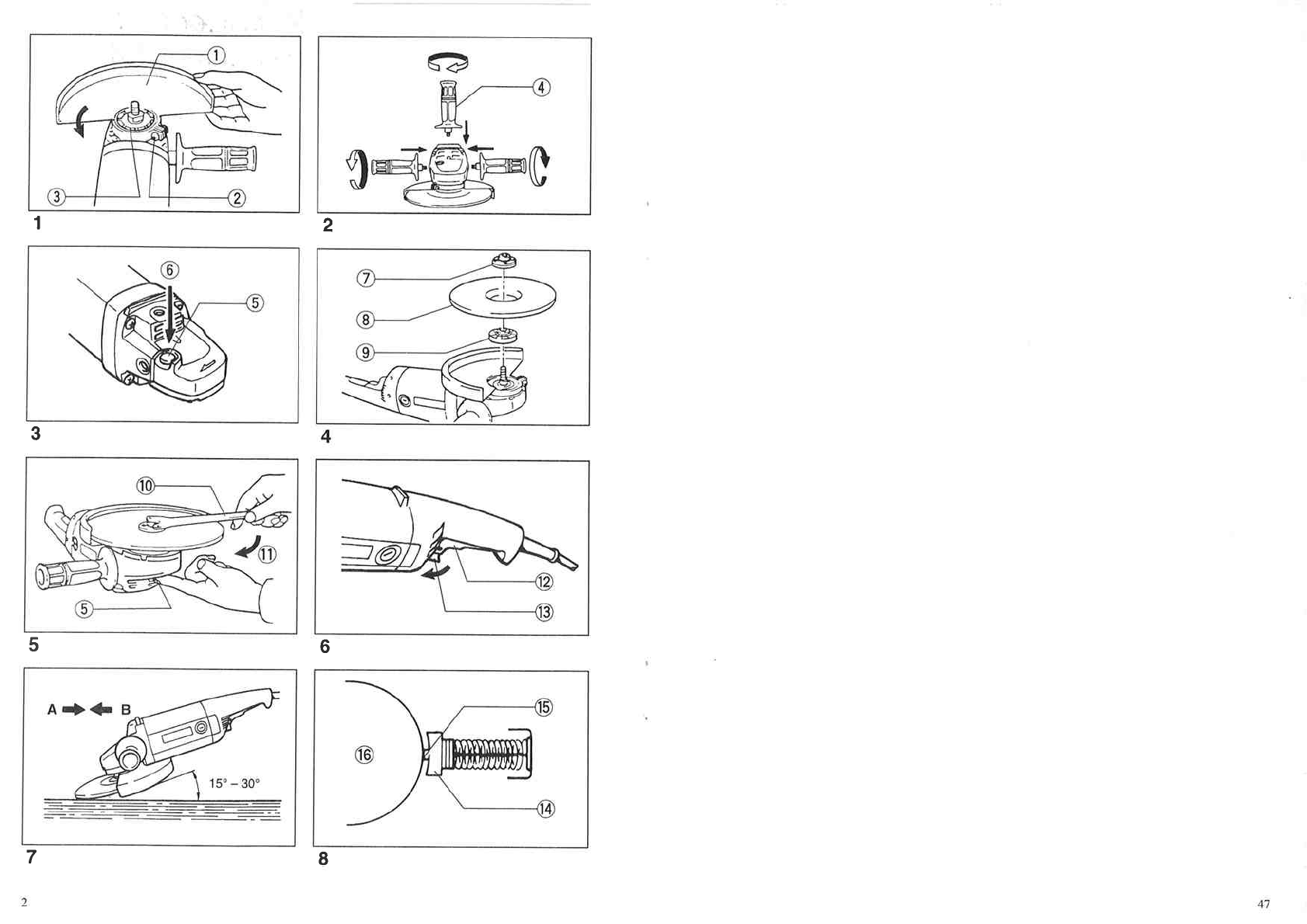

Shaft lock (Fig. 3)

Press the shaft lock to prevent spindle rotation when

installing or removing accessorjes.

CAUTION:

Never acluate the shaft lock when the spindle is

moving. The machine may be damaged.

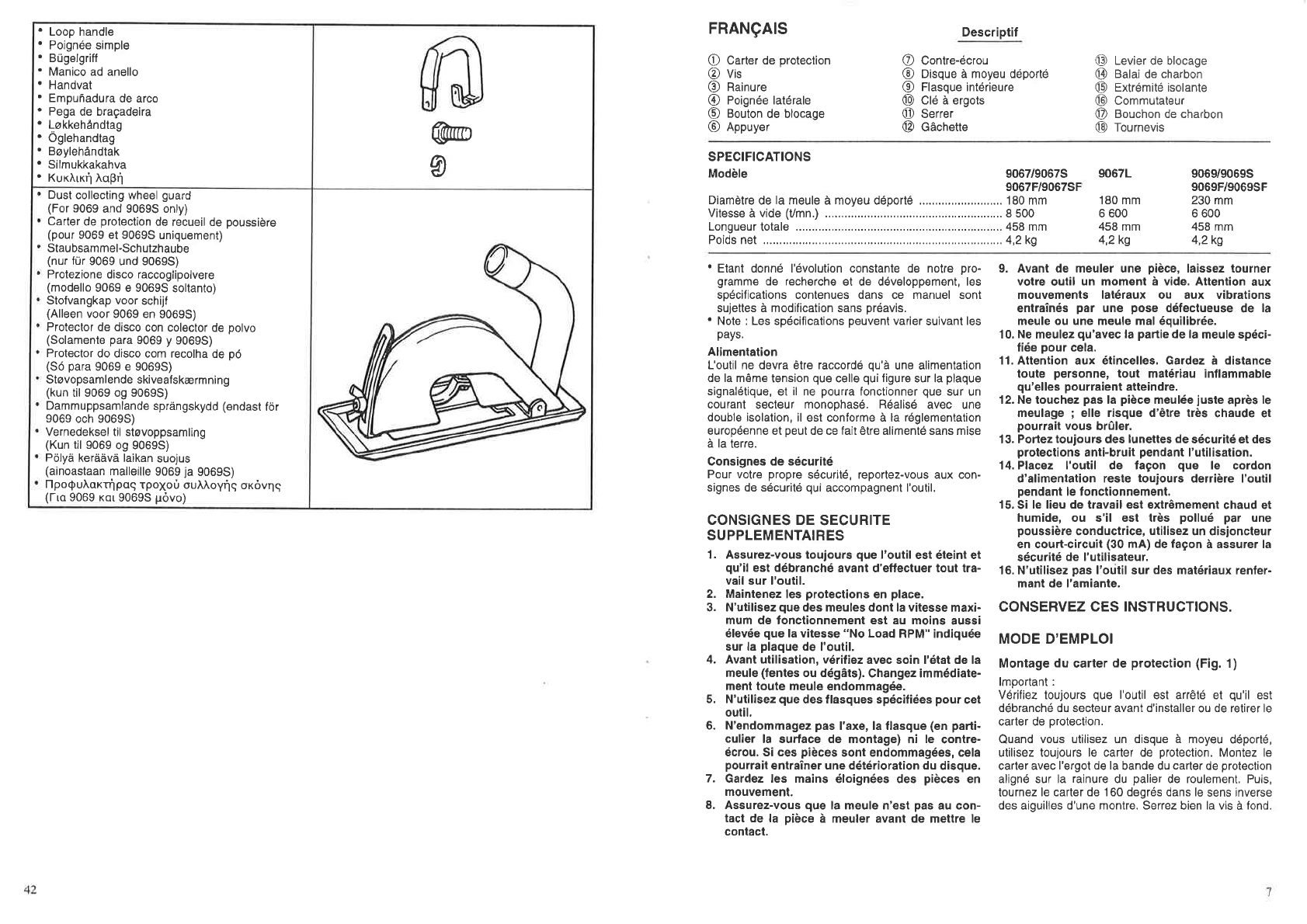

lnstalling or removing depressed center

wheel (Fig.4&5)

lmoortant:

Always be sure that the mach¡ne is switched off and

unplugged before rnstalling or removing the wheel.

Mount the inner flange onto the spindle. Fit the wheel

on over the inner flange and screw the lock nul onto

the spindle.

To tighten the lock nut, press the shaft lock firmlv so

that the spindle cannot revolve, then use the locÉ nut

wrench and securely tighten clockwise.

To remove the wheel, follow the installation procedure

in reverse.

NOTE:

Super flange

Models 9067F, 9069F, 9067SF and 9069SF are

standard-equipped with a super flange.

Only 1/3 of efforts needed to undo lock nut, comoared

w¡th convent¡onal type.

Switch action (Fig.6)

CAUTION:

Before plugging in the machine, always check to see

that the switch trigger actuates properly and returns to

the "OFF" position when released.

For U.K., Australia, New Zealand, France, Réunion

and Algeria

To prevent the trigger from being accidentally actu-

ated, a lock lever is provided. To start the machine.

push the lock lever in and then pull the trigger.

Release the trigger to stop.

For cermany, Austr¡a, ltaly, Netherlands, Belgium,

Spain, Portugal, Denmark, Sweden, Noiwa¡

Finland, Greece and South Africa

locked position, pull the trigger fully, then release it.

For other countr¡es than the above countr¡es

T! , simply pull

tne or continuou

trig sh the locr

ma ked position,

Ine

NOTE:

Models 90675 and 90695 begin to run slowly when

they are turned on. This soft start feature assures

smoother operalion and less operator fatigue.

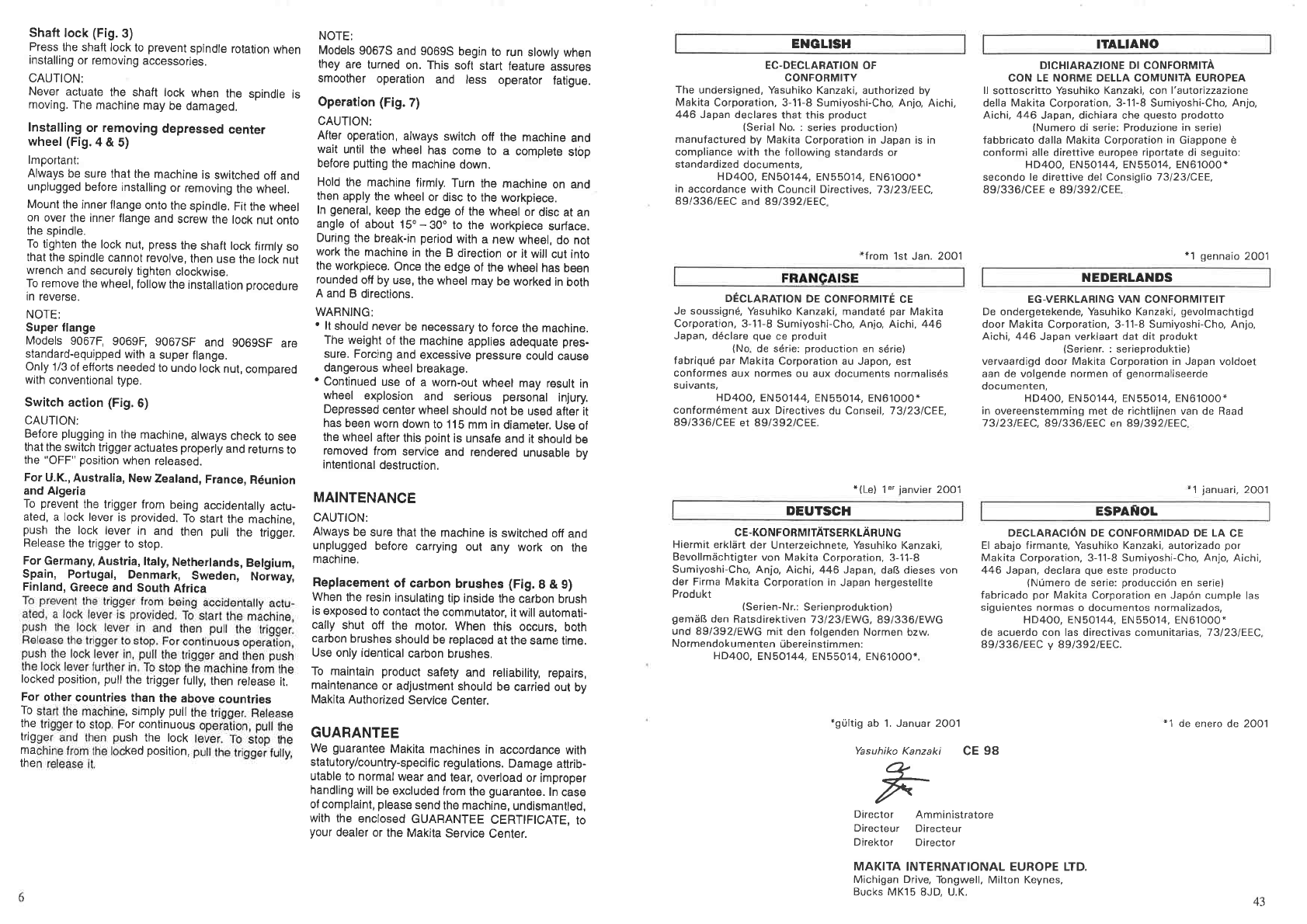

Operation (Fig.7)

CAUTION:

After operation, always switch off the machine and

wait until the wheel has come to a complete stop

before putting the machine oown.

Hold the machine firmfy. Turn the machine on and

then apply the wheel or disc to the workpiece.

ln general, keep the edge of the wheel or disc at an

angle of about 15"-30. to the workoiece surface.

During the break-in period with a new wheel, do not

work the machine in the B direction or it will cut into

the workpiece. Once the edge of the wheel has been

rounded off by use, the wheel may be worked in both

A and B directions.

WARNING:

. lt should never be necessary to force th€ machine.

The weight of the machine applies adequate pres-

sure. Forcing and excessive pressure could cause

dangerous wheel breakage.

'Continued use of a worn-out wheel may result in

wheel explos¡on and serious personal injury.

Depressed center wheel should not be used after it

has been worn down to'l1S mm in diameler. Use of

the wheel after this poinl is unsafe and ¡t should be

removed Írom service and rendered unusable bv

intentional destruct¡on.

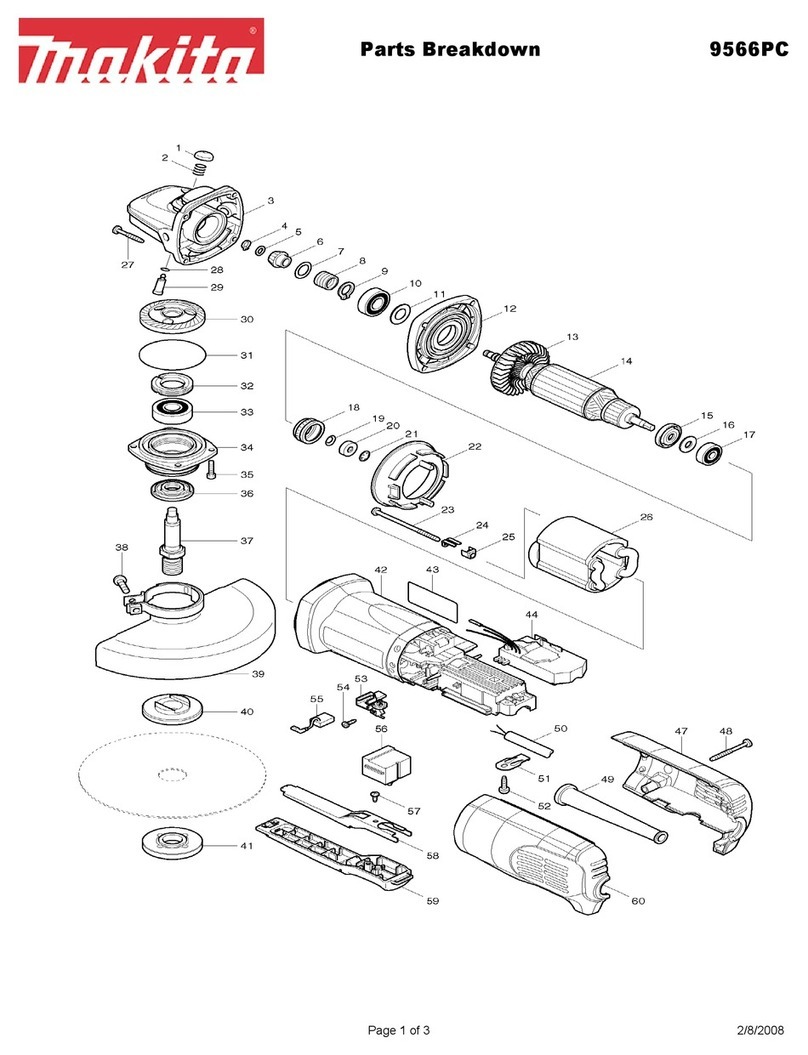

MAINTENANCE

CAUTION:

Always be sure that the machine is switched off and

unplugged before carrying out any work on the

machine.

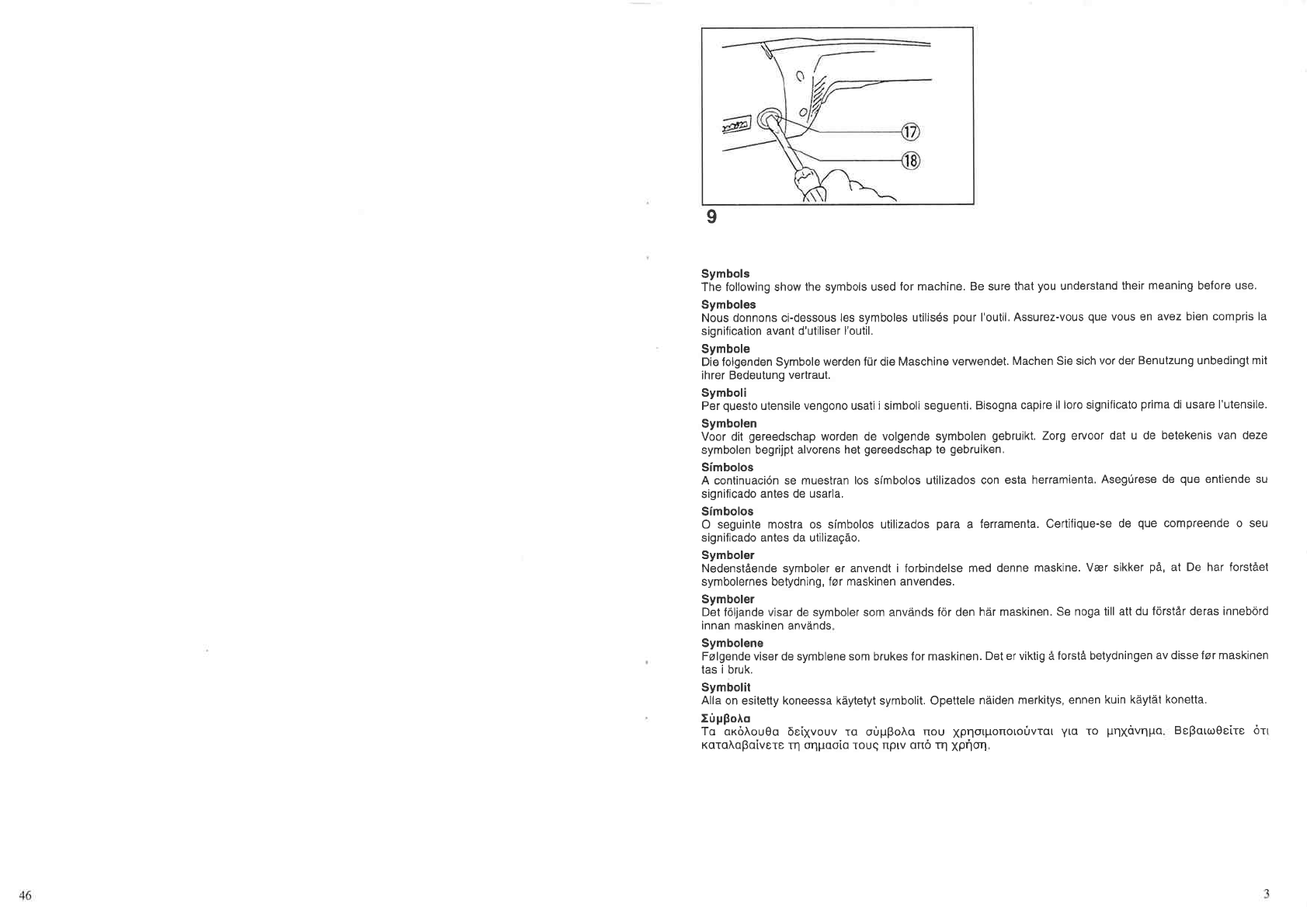

Replacement of cârbon brushes (Fig. I & 9)

When lhe resin insulating tip inside the carbon brush

is exposed to contact the commulator, it will automati-

cally shut off the motor. When this occurs, both

carbon brushes should be replaced at lhe same time.

Use only ídentical carbon brushes.

To maintain product safety and reliability, repairs,

maintenance or adjustment should be car¡'ied out by

Makita Authorized Service Center.

GUARANTEE

We guarantee Makita machines in accordance wilh

statutory/country-specific regulations. Damage attrib-

utable to normal wear and tear, overload o¡ improper

handling will be excluded from the guarantee. ln case

of complaint, please send the machine, undismanlled,

with the enclosed GUARANTEE CERTIFICATE, to

your dealer or the Mak¡ta Service Center.

EC-DECLARATION OF

CONFORMITY

The unders¡gned, Yasuhiko Kanzaki, authorized by

Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi,

446 Japan declares that this product

(Serial No. : series Droduction)

manufactured by Makita Corporation in Japan is in

compliance with the follow¡ng standards or

standardized documents,

HD400, EN50144, EN55014, EN61000-

in accordance w¡th Counc¡l D¡rectives. 73l23lEEC,

89/336/EEC and 89/392/EEC

DÉCLARATIoN DE coNFoRMITÉ cE

Je soussigné, Yasuhiko Kanzaki, mandaté par Mak¡tâ

Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi, 446

Japan, déclare que ce produit

{No de série: production en série)

fabriqué par Mak¡ta Corporâtion au Japon, est

conformes aux normes ou aux documents normalisés

sulvanls,HD400, EN50144, EN55014, EN61000*

conformément aux Directives du Conseil, 73l23lCEE,

89/336/CEE et 89/392/CEE.

*(Le) 1er janvier 2O01

DEUïSGt{

C E-KO N FORM ITÄTS E R KLÄR UNG

Hiermit erklärt der Unterzeichnete, Yasuhiko Kanzaki.

Bevollmächtigter von Makita Corporation, 3-11-8

Sumiyoshi-Cho, Anjo, Aichi, 446 Japan, daß dieses von

der Firma Makita Corporation in Japan hergestellte

Produkt (Serien-Nr.: Serienproduktion)

gemäß den Ratsdirektiven 73l231EWG, 89/336/EWG

und 89/392/EWG mit den folgenden Normen bzw.

NoÌmendokumenten übereinstimmen:

HD400, EN50144. ENs5014, EN61000..

DICHIARAZIONE DI CONFORMITÀ

CON LE NORME DELLA COMUNITA EUROPEA

ll sottoscr¡tto Yasuhiko Kanzaki, con I'autorizzazione

della Makita Corporat¡on, 3-11-8 Sumiyoshi-Cho, Anjo,

Aichi, 446 Japan, dichiara che questo prodotto

(Numero di serie: Produzione in seriel

fabbr¡cãto dalla Makita Corporation in Giappone è

conformi alle dirett¡ve europee riportate di seguito:

HD400, EN50144, EN55014, EN61000*

secondo le direttive del Consiglio 73l23lCEE,

89/336/CEE e 89/392/CEE

*1 gennaio 2001

NEDERLAI'DS

EG-VERKLARING VAN CONFORMITEIT

De ondergetekende, Yasuhiko Kanzaki, gevolmachtigd

door Makita Corporat¡on, 3-11-8 Sumiyoshi-Cho, Anjo,

Aichi, 446 Japan verklaart dat dit produkt

(Serienr. : serieproduktie)

vervaardigd door Makita Corporation in Japan voldoet

aan de volgende normen of genormaliseerde

documenten.

HD400, EN50144, EN55014, EN61000*

¡n overeenstemming met de richtlijnen van de Raad

13123|EEC, 89/336/EEC en 89/392/EEC

*1 januari, 2OO1

ESPANOL

DECLARACIÓN DE CONFORMIDAD DE LA CE

El abajo firmante, Yasuhiko Kanzaki, aulor¡zado por

Makita Corporation, 3-1'l-8 Sumiyoshi-Cho, Anjo, Aichi,

446 Japan, declara que este producto

(Número de serie: producción en serie)

fabricado por Makita Corporation en Japón cumple las

siguientes normas o documentos normalizados,

HD400, EN50144, EN550'14. EN61000*

de acuerdo con las directivas comunitarias, 73l23lEEC,

89/336/EEC v 89/392/EEC.

ENGLISI{ ITALIAl{O

*gültig ab 1. Januar 2OO1

Yasuhiko Kanzaki CE 98

&

+

,/7,

v

D¡rector Ammin¡stratore

Directeur Directeur

Direktor Director

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, U.K.

*'l de enero de 2OO1

*from 1st Jan. 2001

43