1CONTENTS

1CONTENTS......................................................................................................................................................................2

2CAUTION.........................................................................................................................................................................3

3NECESSARY REPAIRING TOOLS................................................................................................................................3

4LUBRICANTANDADHESIVEAPPLICATION...........................................................................................................3

5TIGHTENING TORQUE SPECIFICATIONS ................................................................................................................4

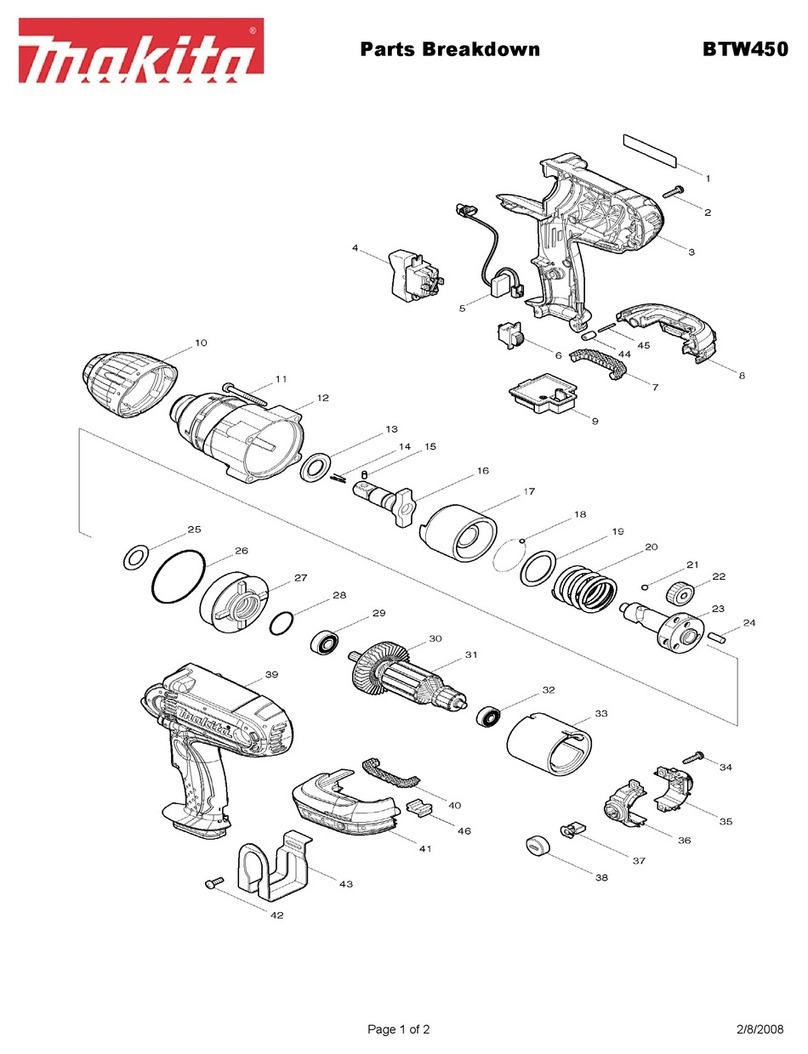

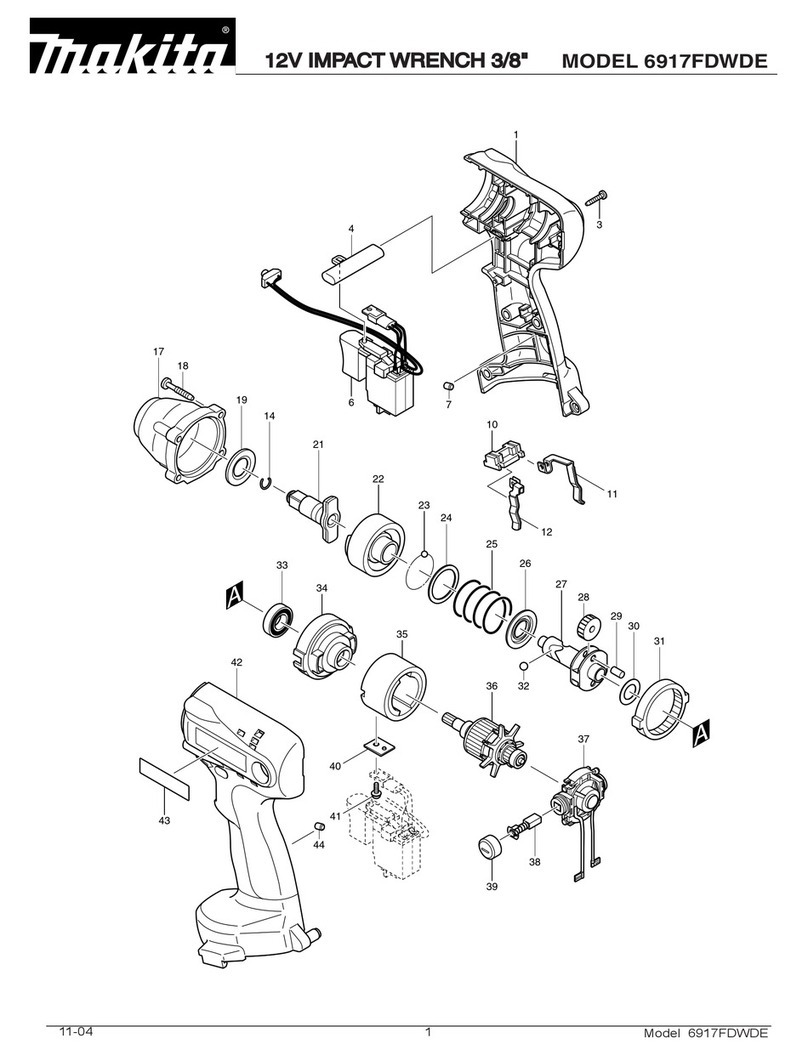

6DISASSEMBLING/ASSEMBLING...............................................................................................................................5

6-1 Advance preparation.................................................................................................................................................5

6-2 Bit sleeve...................................................................................................................................................................5

6-2-1 Disassembling...................................................................................................................................................5

6-2-2 Assembling.......................................................................................................................................................6

6-3 Hammer case ............................................................................................................................................................6

6-3-1 Disassembling...................................................................................................................................................6

6-4 Hammer ....................................................................................................................................................................9

6-4-1 Disassembling...................................................................................................................................................9

6-4-2 Assembling.....................................................................................................................................................10

6-5 Hammer case ..........................................................................................................................................................12

6-5-1 Assembling.....................................................................................................................................................12

6-6 Rotor and other electric parts ..................................................................................................................................13

6-6-1 Disassembling.................................................................................................................................................13

6-6-2 Assembling.....................................................................................................................................................16

7CIRCUIT DIAGRAM ....................................................................................................................................................20

8WIRING DIAGRAM .....................................................................................................................................................21

9TROUBLE SHOOTING ................................................................................................................................................23

9-1 Note in Repairing....................................................................................................................................................23

9-2 Flowchart of Troubleshooting.................................................................................................................................24

9-3 Short-circuit test on FET (Field Effect Transistor) of controller.............................................................................26