P 3/ 37

Repair

CAUTION: Unplug the tool and remove the saw blade from the machine for safety before

repair/ maintenance in accordance with the instruction manual!

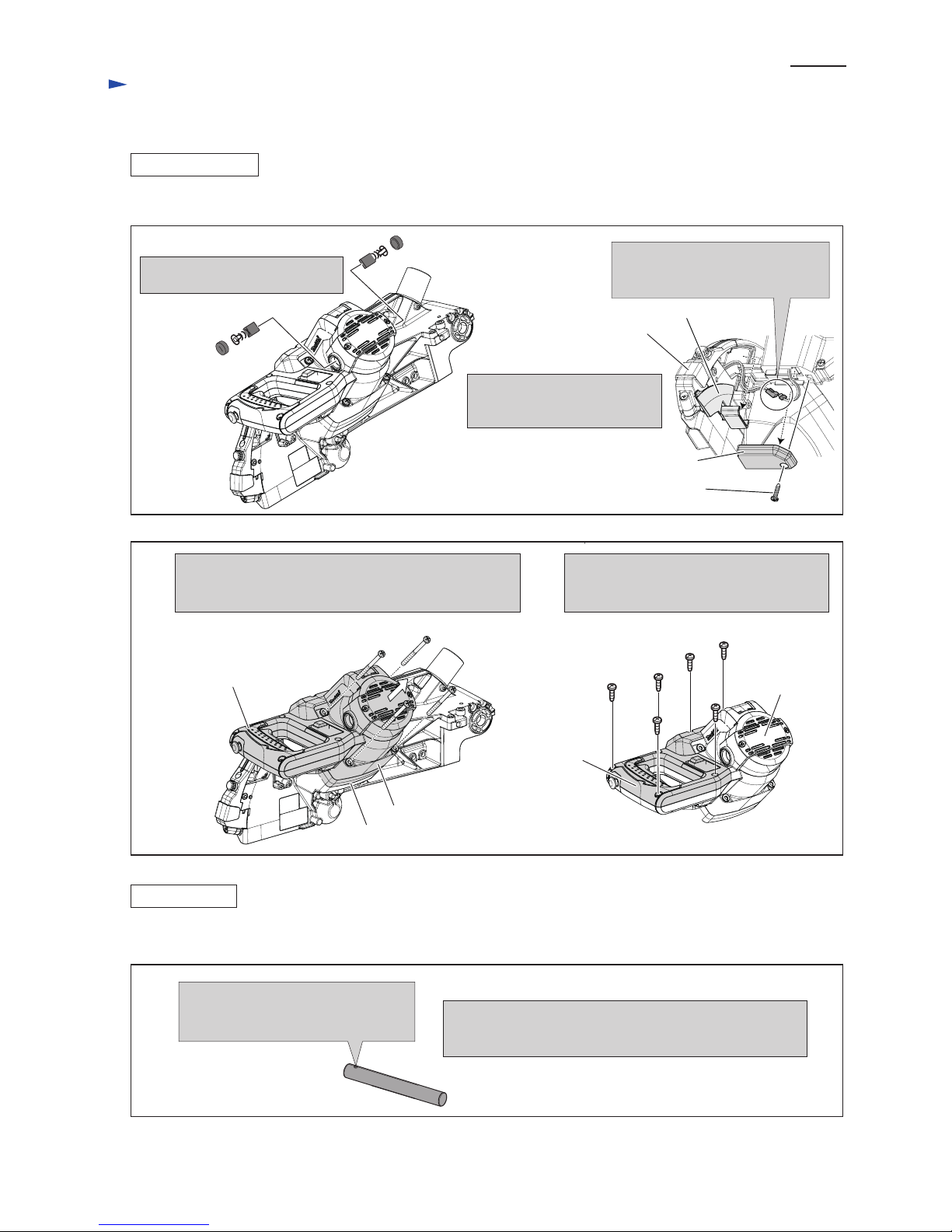

[1] NECESSARY REPAIRING TOOLS

[2] LUBRICATIONS

Code No. Description Use for

1R028 Bearing setting pipe 20-12.2 Mounting Retaining ring S-12

1R031 Bearing setting pipe 28-12.2 Mounting Helical gear 27

1R034 Bearing setting plate 12.2 Mounting Helical gear 27

1R036 Bearing setting plate 17.2 Mounting Helical gear 28

1R045 Gear extractor (large) Mounting / Removing Helical gear 14

1R207 45-degree set square Adjusting the bevel angle of Saw blade to 45 degree

1R208 90-degree set square Adjusting the bevel angle of Saw blade to 90 degree

1R217 Ring 22 Removing Helical gear 27

1R220 Ratchet head 27 Attachment for 1R254

1R222 Socket adapter Attachment for 1R254

1R232 Pipe 30 Mounting Helical gear 28

1R254 Torque wrench shaft 2 - 6 N.m Tightening Hex lock nut M10-17

1R269 Bearing extractor (small) Removing Ball bearings

1R291 Retaining ring S and R pliers Removing Retaining ring in Gear section

1R315 Laser beam positioning jig Adjusting Laser beam

253771-0 Flat washer 16 Adjusting Laser beam

782232-8 Box wrench 13 (standard accessory) Installing /Removing Blade Adjusting Blade position

134829-3 Socket 17-38 assembly Attachment for 1R254

1R346 Center attachment Attachment for 1R045

1R361 Bearing retainer wrench 14-23 Mounting / Removing Bearing retainer wrench 14-23

Apply Lubricants to the designated portions in order to protect parts and product from unusual abrasion.

Fig. 4

Item No. Description Portion to lubricate Lubricant Amount

a little

Cam Tip portion which contacts with 196 Leaf spring

Whole portion

Pin portion for receiving Stopper

180

161

190

Arm section

Arm complete

Portion where Arm’s hole without thread contacts

Rubber ring 9

195 Lock pin 8 Portion where Compression spring 6 contacts VG100 designated with

designated with

designated with

196 Leaf spring Surface where 195 and Compression spring 6 contact

197 Center shaft

161

190

Stopper

Retaining ring S-12

Flat washer 12

M10 Hex bolt as an axis of Lever 105

180

Pin portion of Arm for receiving Stopper

Lever 105

195

196

197

Makita grease SG.No.00

Makita grease SG.No.00

Compression

spring 6