Makita LS1216F User manual

Other Makita Saw manuals

Makita

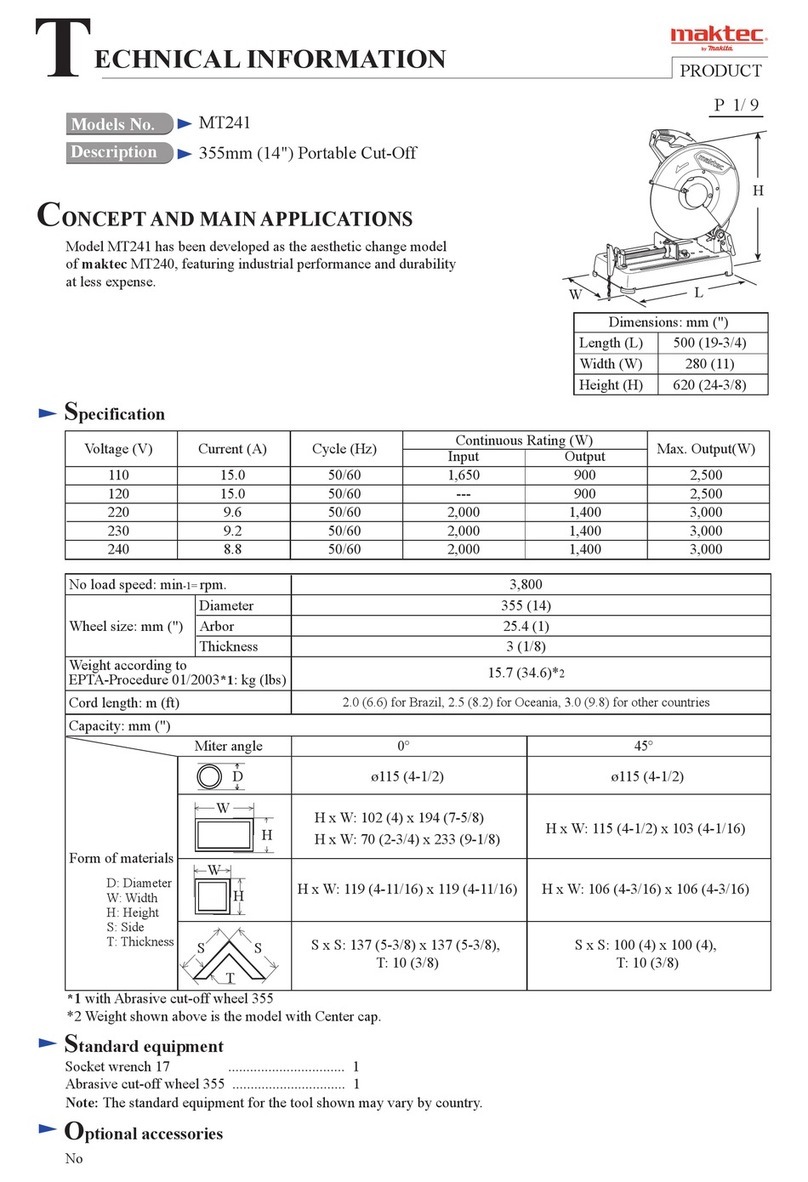

Makita Maktec MT241 Manual

Makita

Makita HS0600 User manual

Makita

Makita DSS611 User manual

Makita

Makita JR1000FT User manual

Makita

Makita LH1201FL User manual

Makita

Makita LC1230 User manual

Makita

Makita LC1230 User manual

Makita

Makita DHS680RMJ User manual

Makita

Makita DLS111 User manual

Makita

Makita 5603R User manual

Makita

Makita LS1040 User manual

Makita

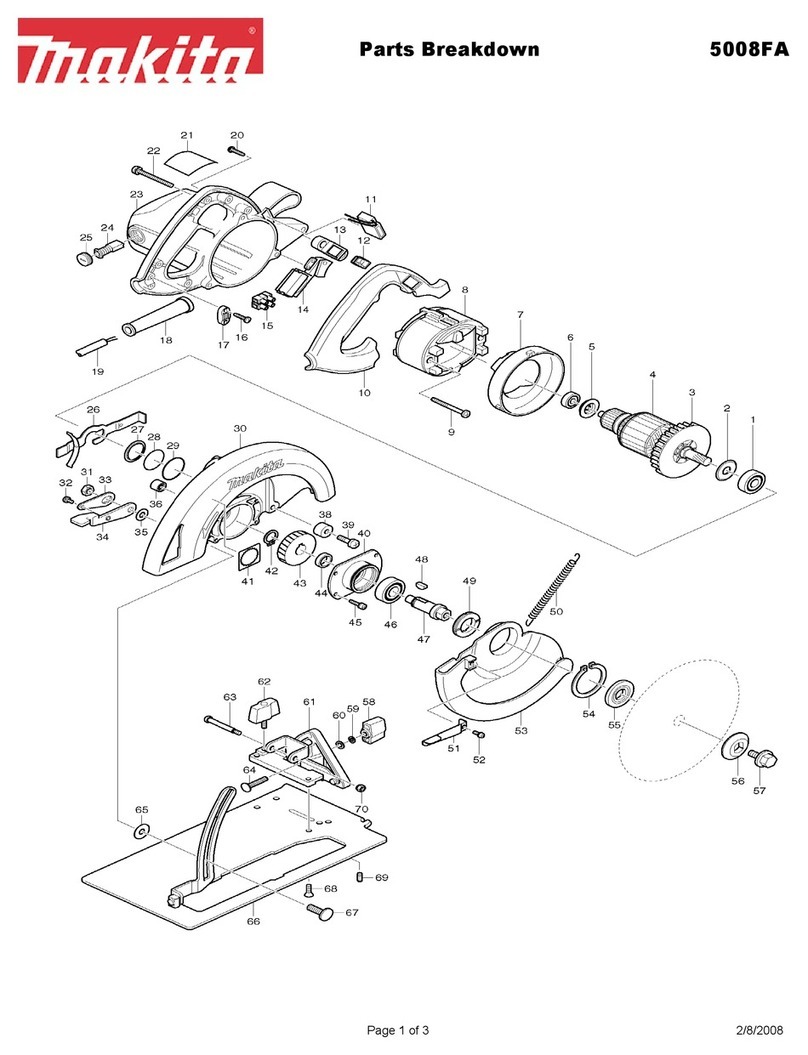

Makita 5008FA Quick start guide

Makita

Makita LS1045 User manual

Makita

Makita MLT100 User manual

Makita

Makita LS0714L User manual

Makita

Makita JR3020 User manual

Makita

Makita DUC101 User manual

Makita

Makita SP6000 User manual

Makita

Makita DLS110 User manual

Makita

Makita M4500 User manual