PRODUCT

P 1/ 12

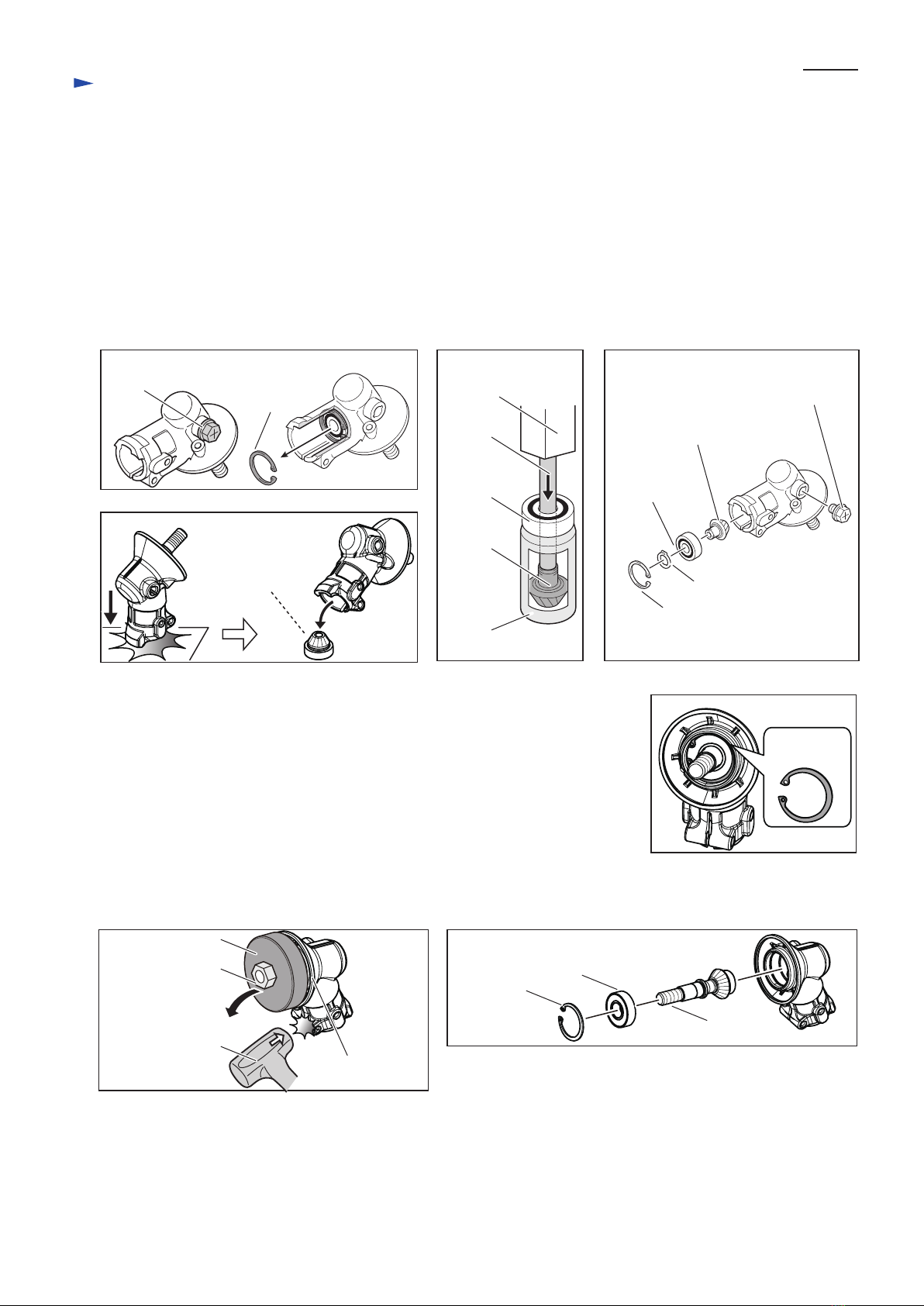

Optional accessories

Cutter blade, Nylon cutting head, Charger DC36RA, Battery BL3626, Pole hedge trimmer attachment (for BBC300L),

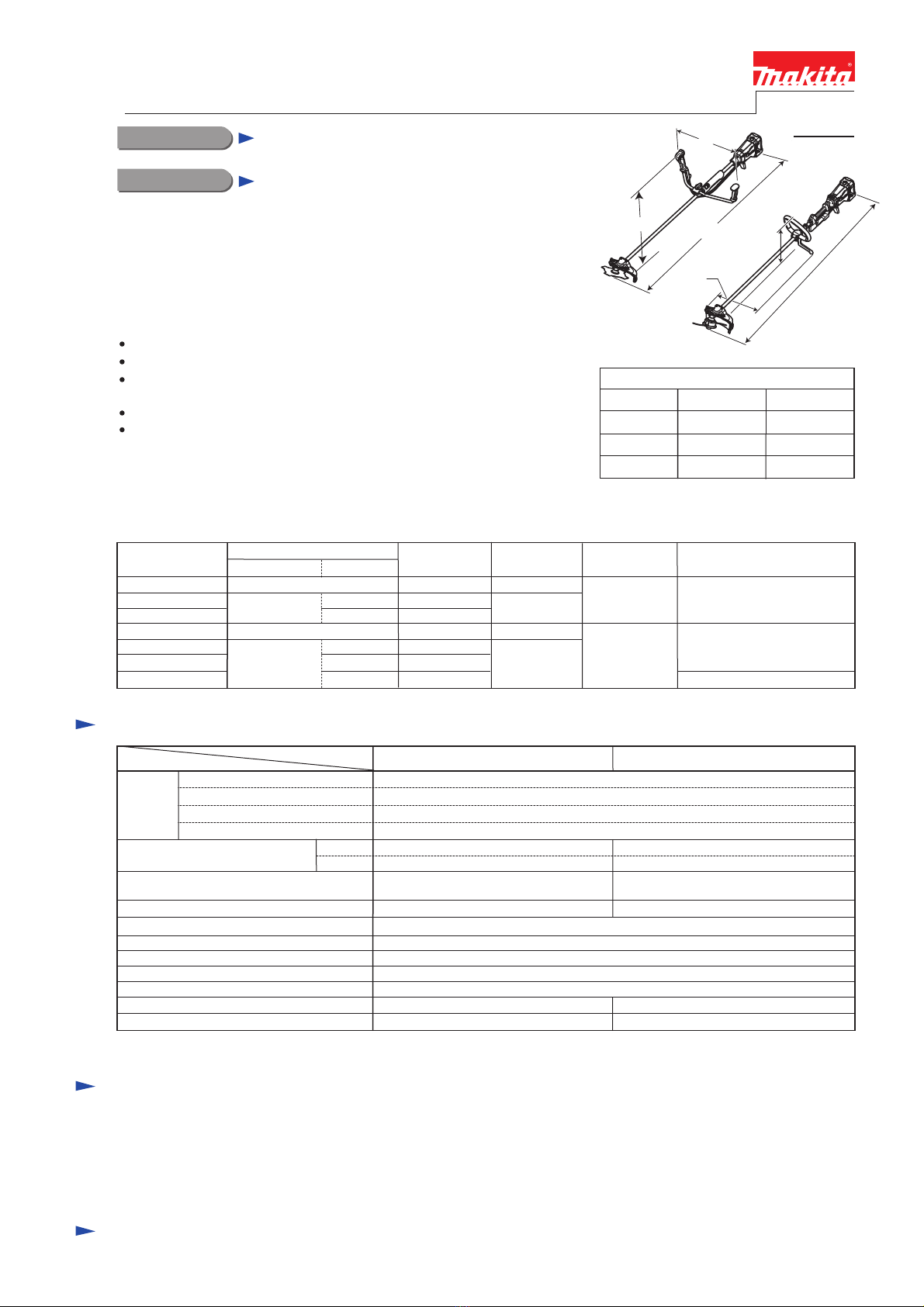

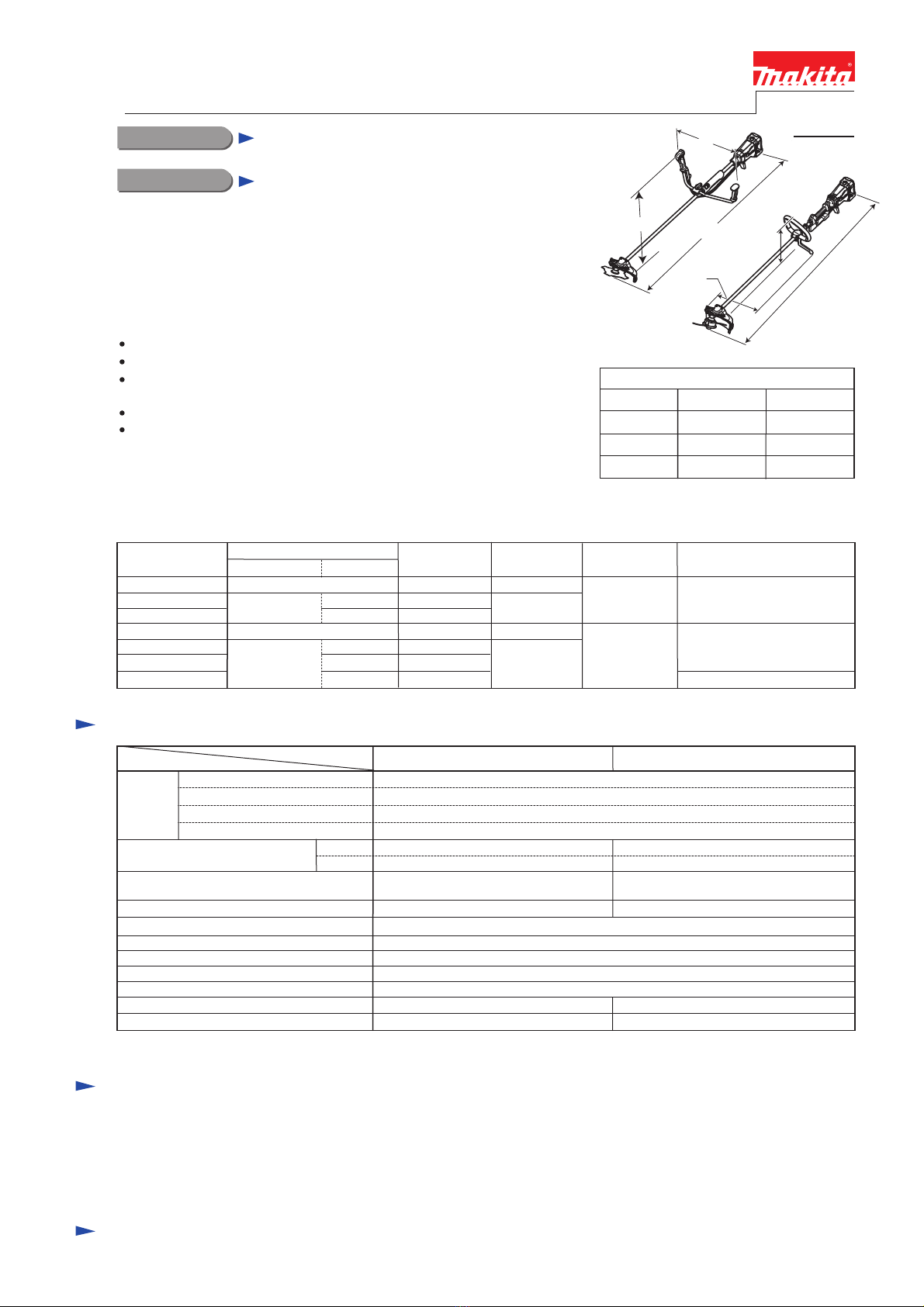

620 (24-3/8) 340 (13-3/8)

Dimensions: mm (")

Width (W)

Height (H)

Length (L)

490 (19-1/4) 325 (12-3/4)

BBC231U BBC300L

BBC231U

BBC300L

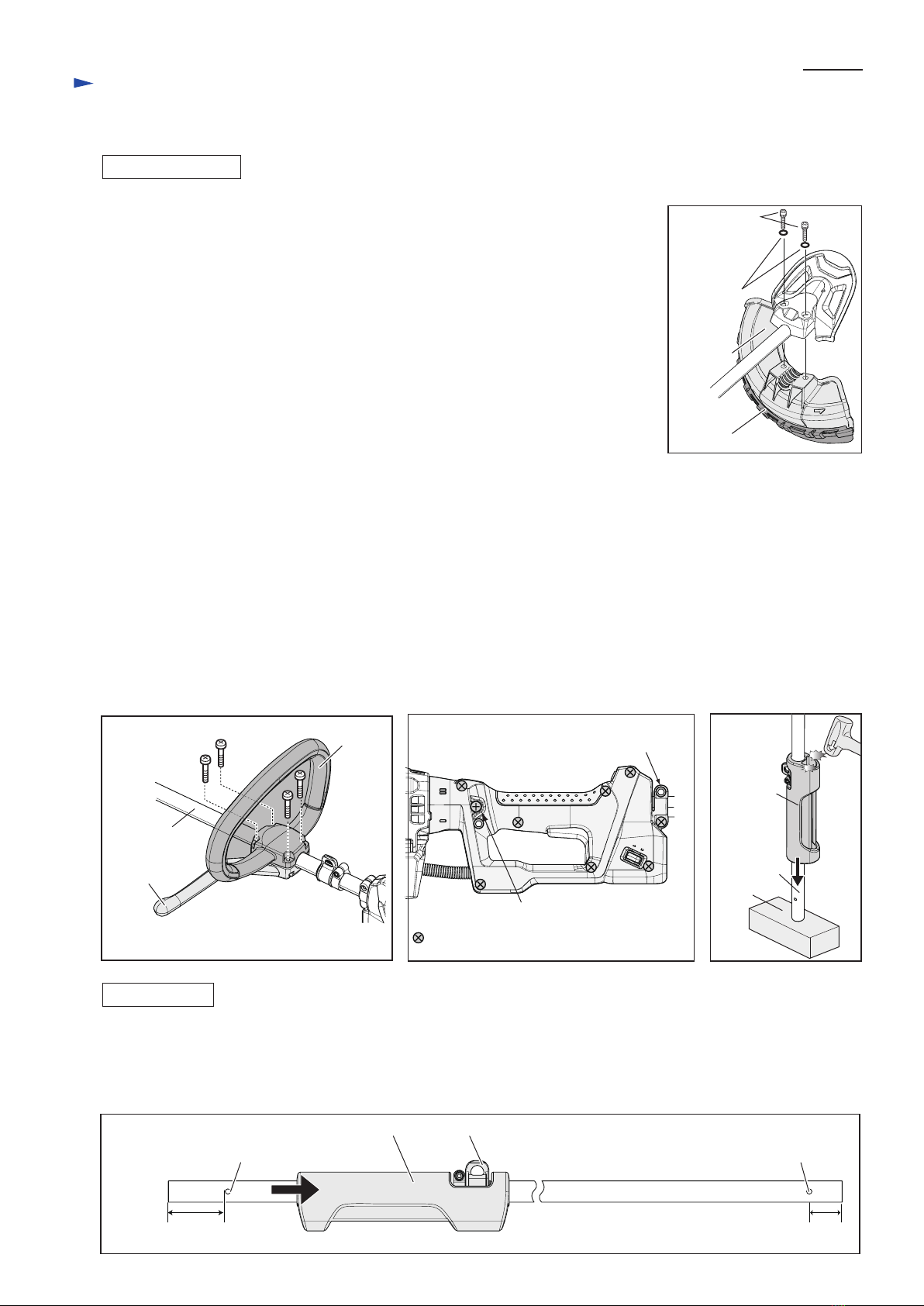

Standard equipment

Note: The standard equipment for the tool shown above may vary by country.

4-tooth star blade 230mm (9") ............................... 1 (for BBC231U)

Blade cover ............................................................ 1 (for BBC231U)

Nylon cutting head (Bump & Feed 4) ................... 1 (for BBC300L)

Shoulder harness with double shoulder straps ....... 1 (for BBC231U)

Shoulder harness with single shoulder strap .......... 1 (for BBC300L)

Universal guard (=Protector) ..................... 1

Socket wrench ............................................ 1

Hex wrench (for M4) ................................. 1

Hex wrench (for M5) ................................. 1

Models No.

Description

CONCEPT AND MAIN APPLICATIONS

BBC231U

BBC300L

Cordless Brushcutter 230mm (9")

Cordless String Trimmer 300mm (11-3/4")

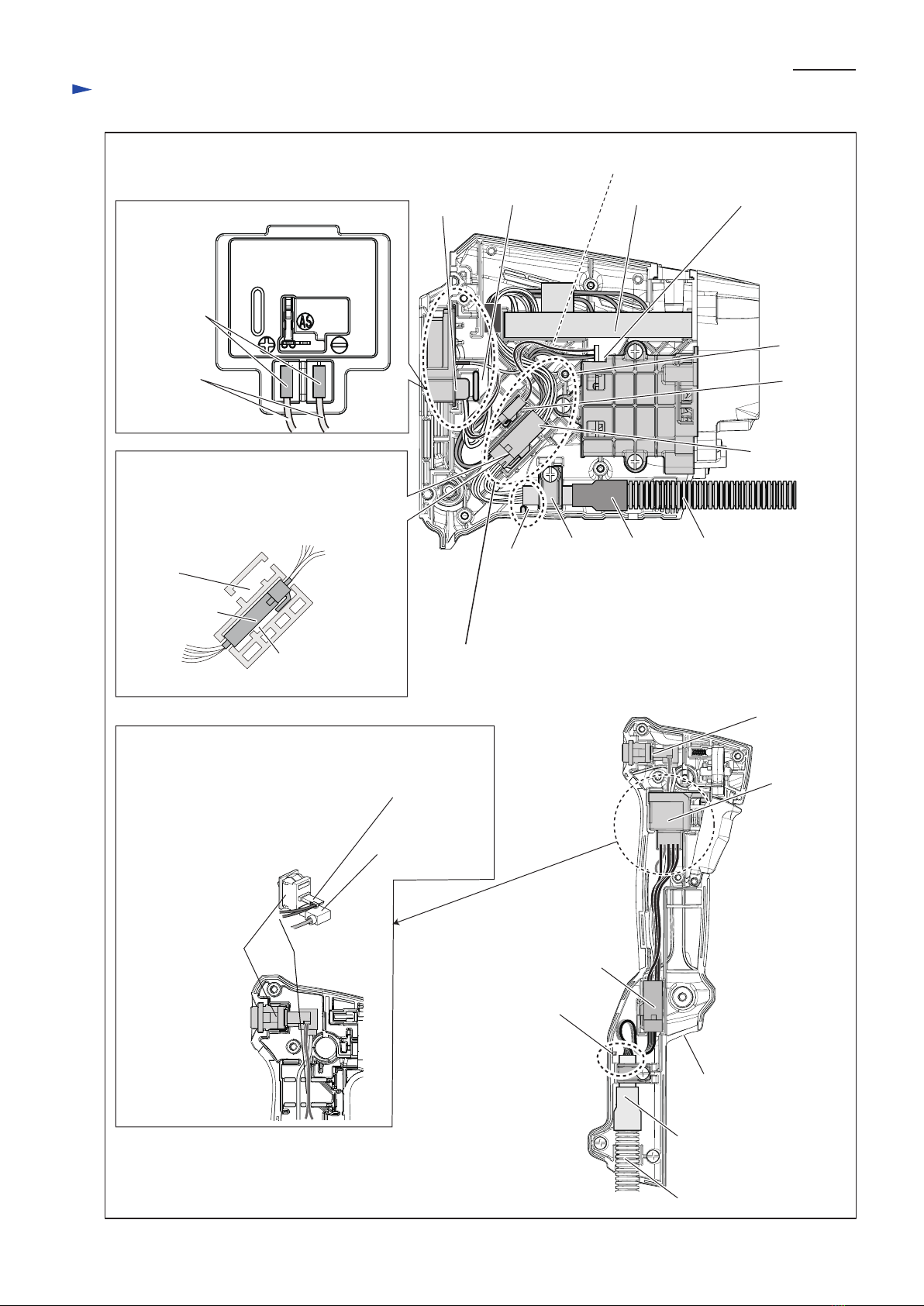

Models BBC231U/ BBC300L are cordless brushcutters/ String trimmer

powered by 36V/2.6Ah Li-ion battery BL3626. As shown below, their

main advantages are "Human- and Environment-friendly" and

"Cost-effective" obtained by using Li-ion battery and Brushless DC motor

as the power unit instead of gasoline and engine:

Zero exhaust emission

Extremely low noise and low vibration

Extra-easy to start operation, simply by loading battery

then pulling switch trigger

Very low running cost owing to no fuel and oil consumption

Almost zero maintenance; no need for oil replacement,

draining fuel for storage, cleaning of air filter/muffler/spark plug,

brush replacement, etc.

With these Makita advantages, the two products will be one of the best

choices for use especially in public places or among residential areas.

Models BBC231U and BBC300L are available in the following variations.

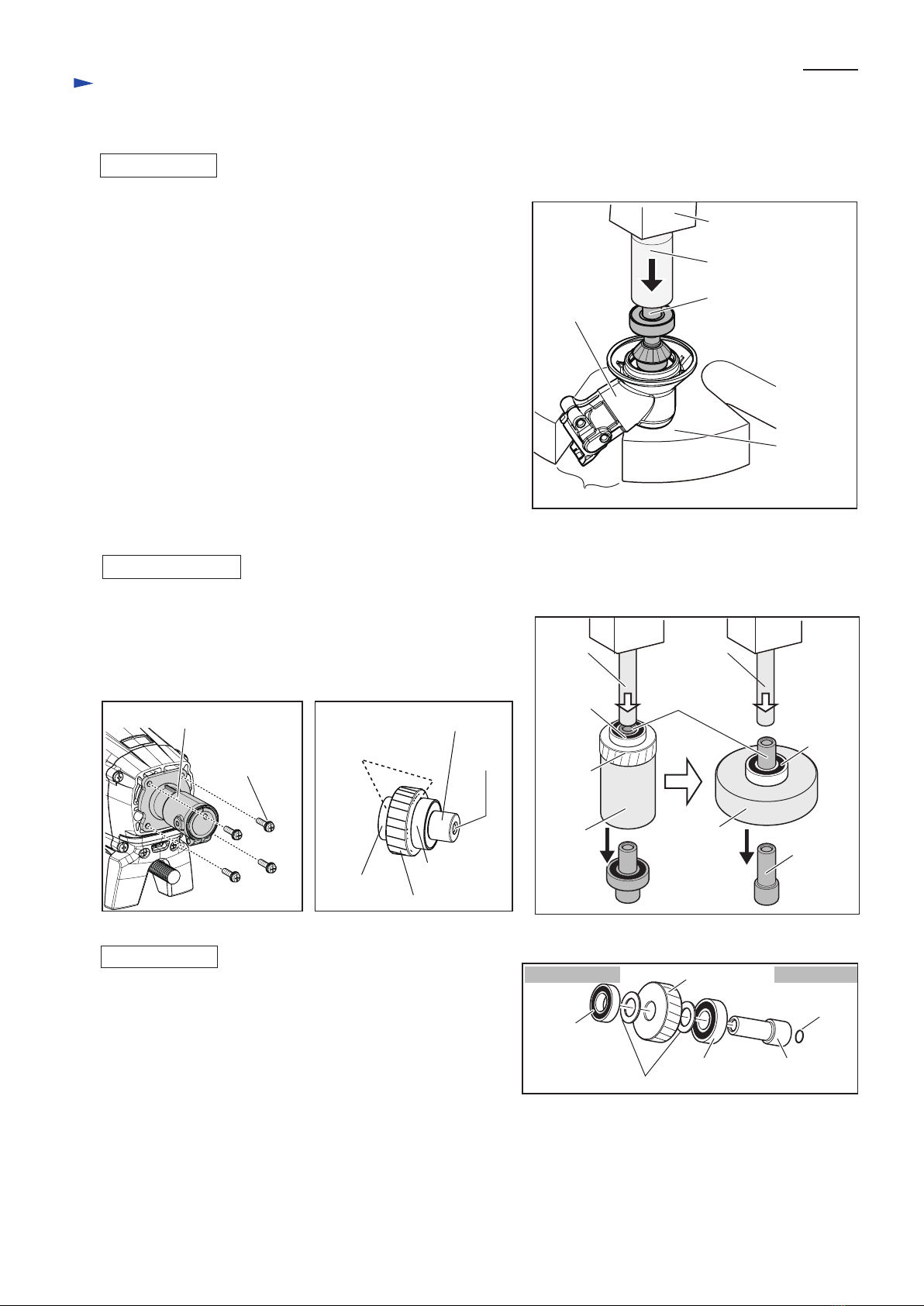

TECHNICAL INFORMATION

1,880 (74) 1,850 (73)

L

H

W

W

L

H

Specification

94

36

Standard cutting tool

Battery

Voltage: V

Li-ion

Specifications Model

Cell

Electric brake Yes

Handle style

Overload protection Current limiter

Net weight*2: kg (lbs)

*1 No load speed of the cutting tool

*2 Weight according to EPTA-Procedure 01/2003, with Cutting tool and Shoulder harness

Nylon cutting head

BBC300L

Loop handle

5.9 (13.0)

No

230mm (9") diameter

BBC231U

Bike handle

7.1 (15.7)

No load speed*1: min.-1 = rpm

YesWaist cushion

22 with DC36RA

Charging time (approx.): min.

Energy capacity: Wh

High

Low

0 - 7,300

0 - 5,300

0 - 6,600

0 - 4,900

4-tooth star blade

Model No. Offered to

type quantity Charger

Battery Battery

cover

BBC231UZ

BBC231URD

BBC231URDE

BBC300LZ

BBC300LRD

BBC300LRDE

BBC300L

No

1

BL3626

BL3626

No

2

1

1

2

No

No

0

0

0

1

1

DC36RA

DC36RA

No

No

all countries

all countries except the

two listed below

USA, Canada

Handle

style

Bike handle

Loop handle

Pole saw attachment (for BBC300L), Cultivator attachment (for BBC300L)

The models also includes the accessories listed below in "Standard equipment".

Variable speed control Yes

Soft start Yes

Reversing switch Yes