Assembly/Disassembly

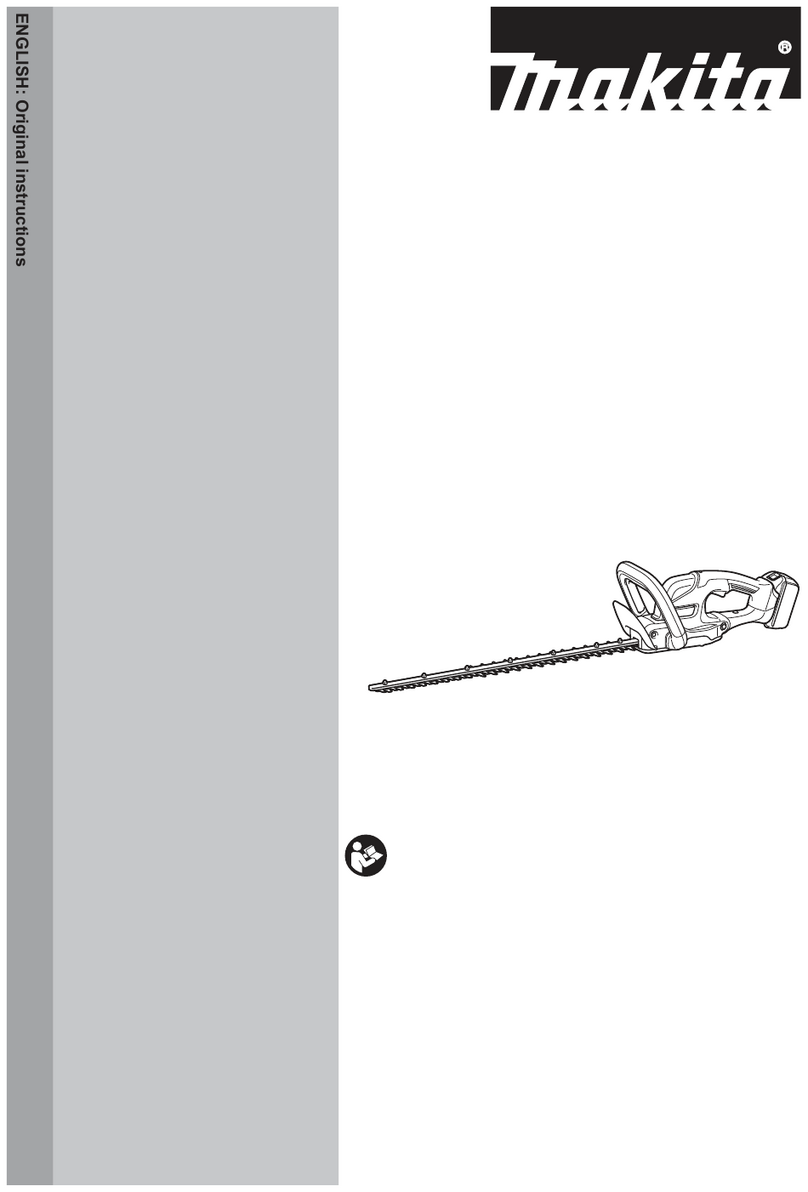

1) Fitting of the gear shaft complete to shear blade assembly

Center thelongholeoftheshearbladesA,Bwiththe

round hole of the guide plate. Center the two crank

plates with that center as shown in the right sketch. Set

ball bearing 6002 and shear blades A,B face to face.

After assembling, check if the shear blades A,B move

smoothly by turning the gear by hand.

Shear blades

The blade A and the blade B have the same weight so that the vibration of the repeated movement can be offset.

Therefore, when there is an inequality of weight due to grinding or breakage of a blade, vibration of the body

becomes big in proportion to the imbalance. In such a case the shear blade assembly should be replaced.

Different parts between #UH4500 and # UH 6300(electrical parts excluded)

(1) Main Body

Substitute parts

Shearbladeassembly 1piece

identificationplate 1piece

Additional parts

none

Excluded parts

none

Repair

Crank Plates(2 sheets)

Ball bearing 6002

Shear blades A,B

Guide plate

Center of the long

hole and the crank plates

(2) Normal Accessories

Substitute piece

Cardboardcase 1

Additional piece

none

Excluded piece

none

Operation Mode

(1) Switch operation

Two different switches should be activated to start

operation because this tool has adopted double hand

switch mechanism. For activation, the main switch on the

grip should be pulled by one hand and the loop-shaped

sub switch on the handle held by the other. If either of the

two switches is released, the machine will stop.

Handle Sub switch

Grip

Main switch