Makita DRT50 User manual

Other Makita Trimmer manuals

Makita

Makita DUN500WRTE User manual

Makita

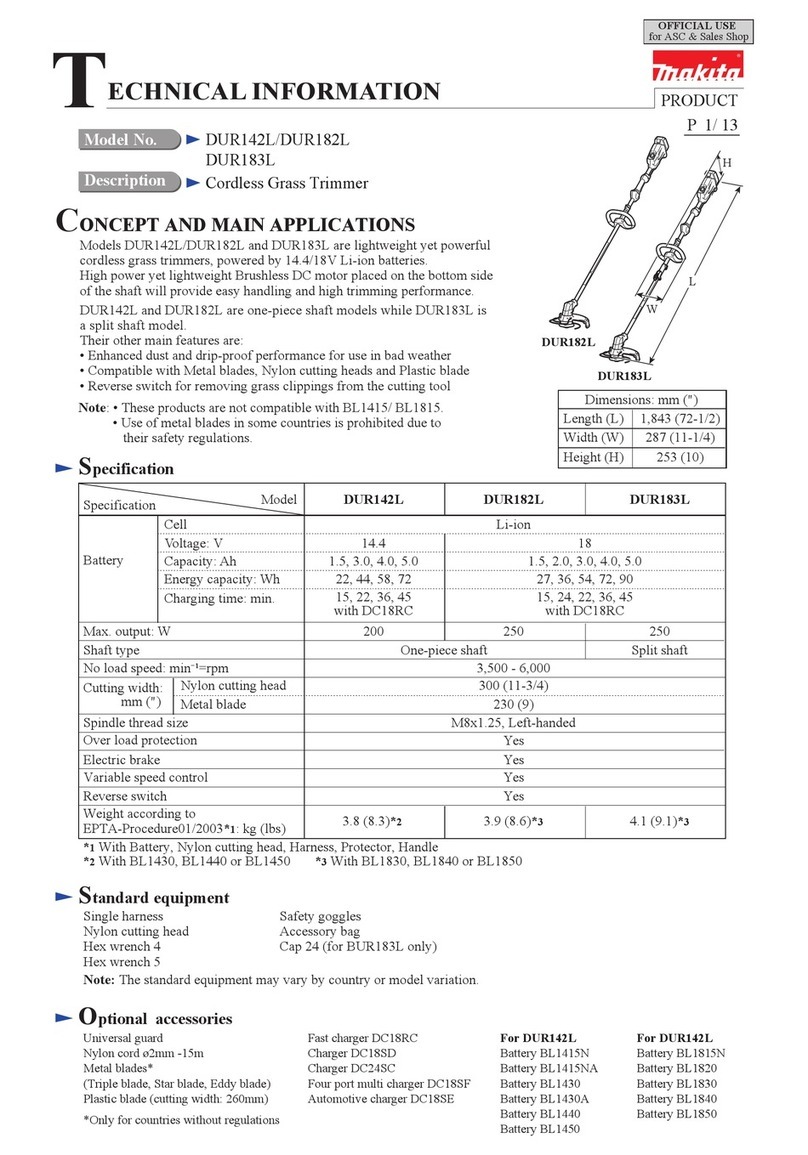

Makita DUR183L User manual

Makita

Makita UH5570 User manual

Makita

Makita EM2600U User guide

Makita

Makita UR013G User manual

Makita

Makita DUH481 User manual

Makita

Makita UR008G User manual

Makita

Makita M3700 User manual

Makita

Makita DUN500W User manual

Makita

Makita GRU02 User manual

Makita

Makita DUR143U User manual

Makita

Makita UM140D User manual

Makita

Makita UH5580 User manual

Makita

Makita UH4570 User manual

Makita

Makita DRT50 User manual

Makita

Makita DUR141 User manual

Makita

Makita HHU01 User manual

Makita

Makita DUH501 User manual

Makita

Makita ER2550LH User guide

Makita

Makita LXT XRU16 Series User manual