WDS

Operation, Maintenance and Installation Manual

Issue 11 Page 1 14/02/2019

Table of Contents

Foreword...........................................................................................................................................................................2

Certifications and Compliances.........................................................................................................................................2

Quality Policy ....................................................................................................................................................................2

Safety Instructions ............................................................................................................................................................3

1.0 Design Parameters ................................................................................................................................................4

1.1 Operating Cycles ........................................................................................................................................4

1. 2 Detergent ...................................................................................................................................................5

1.3 Device Features ..........................................................................................................................................6

1.4 Control LCD Display Features .....................................................................................................................6

1.5 Operating Features ....................................................................................................................................6

2.0 Installation and Commissioning ............................................................................................................................8

2.1 Installation .................................................................................................................................................8

2.2 Service Connection and Layout Details ....................................................................................................10

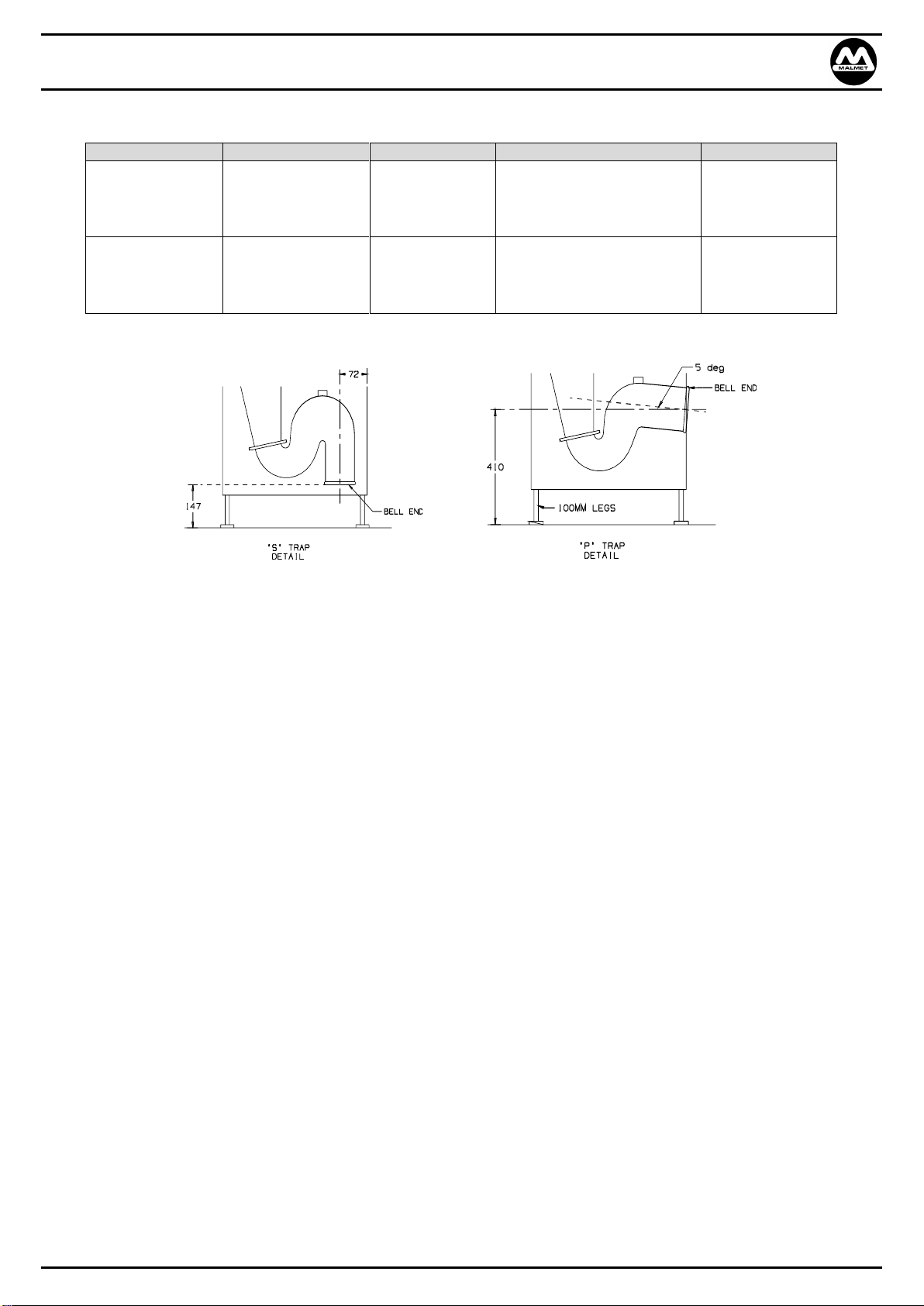

2.3 Plumbing ..................................................................................................................................................11

2.4 Electrical...................................................................................................................................................12

2.5 Commissioning .........................................................................................................................................12

3.0 Loading and Operating .............................................................................................................................................13

3.1 Urinal Bottle / Bedpan - Loading..............................................................................................................13

3.2 Urinal Bottle / Bedpan - Operating Cycle.................................................................................................13

3.3 Urinal Bottle ONLY - Loading....................................................................................................................15

3.4 Urinal Bottle ONLY - Operating Cycle.......................................................................................................15

3.5 Bowl / Utensil - Loading ...........................................................................................................................17

3.6 Bowl / Utensil - Operating Cycle ..............................................................................................................17

4.0 Cycle of Operation.....................................................................................................................................................19

4.2 Detergent Warnings.................................................................................................................................24

4.3 Fault Indication ........................................................................................................................................24

5.0 Maintenance .............................................................................................................................................................25

5.1 Daily Maintenance (Operator or Maintenance Technician) ....................................................................25

5.2 Bi-Monthly Maintenance (Maintenance Technician)...............................................................................25

5.3 Recommended Preventative Maintenance Schedule...............................................................................26

5.4 Fault Codes...............................................................................................................................................27

5.5 Purge Reset (Operator) ............................................................................................................................30

5.6 Purge Detergent Line (Operator) .............................................................................................................30

5.7 Purge Reset (Maintenance)......................................................................................................................31

5.8 Purge Detergent Line (Maintenance).......................................................................................................31

5.9 Detergent Level and Load Cell Calibration...............................................................................................32

5.10 Device Service Component Identification and Part Listing.......................................................................33

5.11 User Menu and Test Mode.......................................................................................................................36

6.0 Technical Data ..........................................................................................................................................................39

6.1 Power and Water Consumption...............................................................................................................39

6.2 Device Specifications................................................................................................................................40

6.3 Wiring Diagram (1ph devices)..................................................................................................................42

6.4 Wiring Diagram (3ph devices)..................................................................................................................43

6.5 Data Logging............................................................................................................................................44

Warranty Statement .......................................................................................................................................................50