Malmet F105BT User manual

Serial Number:

Supplied to:

Date Installed:

Installed by:

It is important that the name from whom you purchased your device and the name of the installer are recorded above. The installer is responsible for the correct

installation, start up and demonstrating the operation of this device. They are also responsible for issuing relevant certificates of compliance (these may differ from

state to state).

Issue 18 Jun-23

Head Office and Customer Service

ABN 95 001 717 791

9-11 McKay Avenue

PO Box 373

Leeton NSW 2705

Phone: +61 2 6953 7677

Fluid Warming Cabinet

Single Models:

F105BT; F420FS; F420C; F210FS; F210C; F210WB; F210S; F260FS; F260C; F260WB; F260S

Combination Models:

FF105FS; FB105FS; FS105FS; FF210FS; FB210FS; FS210FS; FF210C; FB210C; FS210C

FF260FS; FB260FS; FS260FS; FF260C; FB260C; FS260C

Operation, Maintenance and Installation

Manual

Note: Due to Malmet’s Policy of continuous product improvement;

design and technical specifications are subject to change without notice.

Fluid Warming Cabinet

Operation, Maintenance and Installation Manual

Issue 18 Page 1 Jun-23

Table of Contents

Foreword..........................................................................................................................................................................2

Certifications and Compliances.........................................................................................................................................2

Quality Policy....................................................................................................................................................................2

Important Warranty Reminder .........................................................................................................................................2

Malmet Head Office and Factory Contact Details .............................................................................................................2

Safety Instructions - Warnings..........................................................................................................................................3

1.0 Design Parameters......................................................................................................................................................4

1.1 Device Operation ..........................................................................................................................................................5

1.2 Control Display Features ...............................................................................................................................................5

1.3 Operating Features .......................................................................................................................................................5

1.4 Changing the set temperature (lock out feature) .........................................................................................................6

1.5 Temperature Cut Out....................................................................................................................................................6

1.6 Temperature Sensor Plate ............................................................................................................................................6

2.0 Installation..................................................................................................................................................................7

2.1 Service Connections ......................................................................................................................................................9

2.2 Device Dimension and Clearances ................................................................................................................................9

3.0 Maintenance.............................................................................................................................................................13

3.1 Preventative Maintenance..........................................................................................................................................13

3.2 Replacement of Safety Devices...................................................................................................................................13

3.3 Trouble Shooting Guide ..............................................................................................................................................14

4.0 Technical Specifications ............................................................................................................................................15

4.1 Device Specifications...................................................................................................................................................15

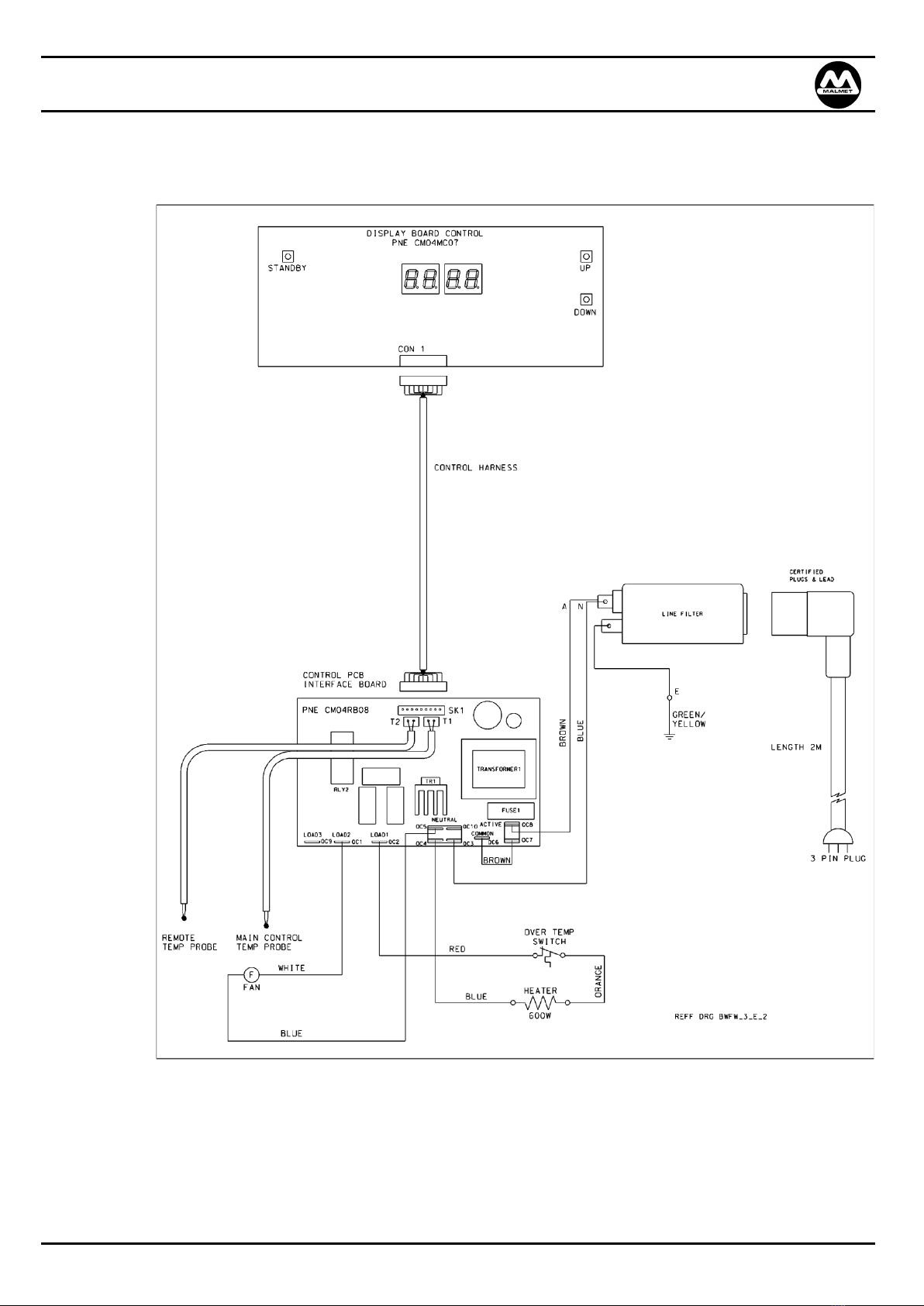

4.2 Wiring Diagram ...........................................................................................................................................................16

Warranty Statement.......................................................................................................................................................17

Fluid Warming Cabinet

Operation, Maintenance and Installation Manual

Issue 18 Page 2 Jun-23

Foreword

To obtain maximum life and efficiency from your Malmet Warming Cabinet and to ensure safe operation, please

read this manual thoroughly and follow all instructions before operating the device.

This manual provides information on the operation of the device. It is recommended that all persons operating the

device have access to this manual for training purposes.

This device is not intended for use by any person without the proper training, experience or knowledge.

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

The specifications supplied in this manual were in effect at the time of publication. However, owing to Malmet

(Australia)’s policy of continuous improvement, changes to these specifications may be made at any time without

notice on the part of Malmet (Australia) Pty Ltd.

Certifications and Compliances

ARTG Registration Number: 188762 Class 1

Electrical Safety: Certificate of Suitability SAA210223 to AS/NZS 60335.1:2020

EMC compliant: IEC 60601-1-2 Emission

Quality Policy

Malmet’s quality management system is certified to ISO 13485:2016 and ISO 9001:2015 and guarantees the

quality of this product.

Important Warranty Reminder

Should you have any problems with your device, contact the company from whom you purchased it, or Malmet

(Australia) Pty Ltd.

It is important that the name from whom you purchased your device and the name of the installer are recorded

on the front page of this manual. The installer is responsible for the correct installation, start up and

demonstrating the operation of this device. They are also responsible for issuing relevant certificates of

compliance (these may differ from state to state).

Malmet Head Office and Factory Contact Details

Malmet (Australia) Pty Ltd

9-11 McKay Avenue

PO Box 373

LEETON NSW 2705

Telephone: +61 2 6953 7677

Website: www.malmet.com.au

Fluid Warming Cabinet

Operation, Maintenance and Installation Manual

Issue 18 Page 3 Jun-23

Safety Instructions - Warnings

Please read and understand this manual before using this device, if this device is used in a manner not specified

by the manufacturer protection by the device may be impaired.

Please refer to this manual for information wherever this warning symbol is displayed -

Be aware of 240 Voltage.

Disconnect power when servicing.

Mains power GPO must be in an accessible position so device can be

isolated from mains power during service.

If the supply cord is damaged it must be replaced by a special cord or

assembly from the manufacturer or its service agent.

Do not overload shelves.

Do not obstruct hot air outlet above top shelf.

Castors where fitted are for convenience but not as a means to be

wheeled across thresholds or similar obstacles. Castors enable the device

to be moved easily aside for cleaning the floor or making space.

Wall mounted units must be mounted to load bearing walls.

All cabinets should be located on a level floor surface and should never be

operated on a sloping surface.

Install temperature probes and element over temperature protection

thermal cut-outs correctly.

This Warming Cabinet is not intended for use by persons (including

children) with reduced physical, sensory, or mental capabilities, or lack of

experience and knowledge.

Fluid Warming Cabinet

Operation, Maintenance and Installation Manual

Issue 18 Page 4 Jun-23

1.0 Design Parameters

Single 105 Litre Fluid Warming Cabinet (Model F105BT) is designed to hold a maximum of 24 litres of fluid in 1

and 2 litre bottles and bags. 105 litre models have 3 shelves with 2 being adjustable; 8 litres per shelf maximum

load.

Single 210 Litre Fluid Warming Cabinets (Models F210FS, F210C, F210WB, F210S) are designed to hold a

maximum of 45 litres of fluid in 1 and 2 litre bottles and bags. 210 litre models have 3 shelves with 2 being

adjustable; 15 litres per shelf maximum load.

Single 260 Litre Fluid Warming Cabinets (Models F260FS, F260C, F260WB, F260S) are designed to hold a

maximum of 60 litres of fluid in 1 and 2 litre bottles and bags. 260 litre models have 4 shelves with 3 being

adjustable; 15 litres per shelf maximum load.

Single 420 Litre Fluid Warming Cabinets (Models F420FS and F420C) are designed to hold a maximum of 105

litres of fluid in 1 and 2 litre bottles and bags. 420 litre models have 7 shelves with 6 being adjustable; 15 litres

per shelf maximum load.

Do not overload shelves. Heated air must be allowed to circulate around the fluid containers.

The temperature can be adjusted up to a maximum of 37°C and has a lock out feature, which allows only

authorised staff to change the temperature.

A fluid temperature sensor plate is located in the cabinet, which enables actual fluid temperature to be

monitored.

All Malmet Fluid Warming Cabinets are designed to be left on permanently.

Electrical Rating 240Vac 50Hz 2.8 Amps supplied with IEC power cord standard 10 Amp plug.

Wall Mounted Place into position and bolt to the wall using the bracket supplied and then plug the unit

into a standard 240V outlet.

This appliance is not intended for use by young children or infirmed persons.

Fluid Warming Cabinet

Operation, Maintenance and Installation Manual

Issue 18 Page 5 Jun-23

1.1 Device Operation

NOTE

The Fluid Warming Cabinet is factory set to 37°C.

We recommend you check with your fluid supplier for the correct temperature.

Before Starting the Device

The device should be run initially on a power supply not protected by an earth leakage circuit breaker for

approximately three hours. This will allow any moisture in the heater to dry out. The device can then be

connected to an earth leakage circuit breaker protected circuit if required.

Plug into standard 240V outlet.

Starting the Device

Press the standby button, the pre-set temperature of the cabinet appears for approximately five seconds. After

five seconds the device switches to display the actual cabinet temperature.

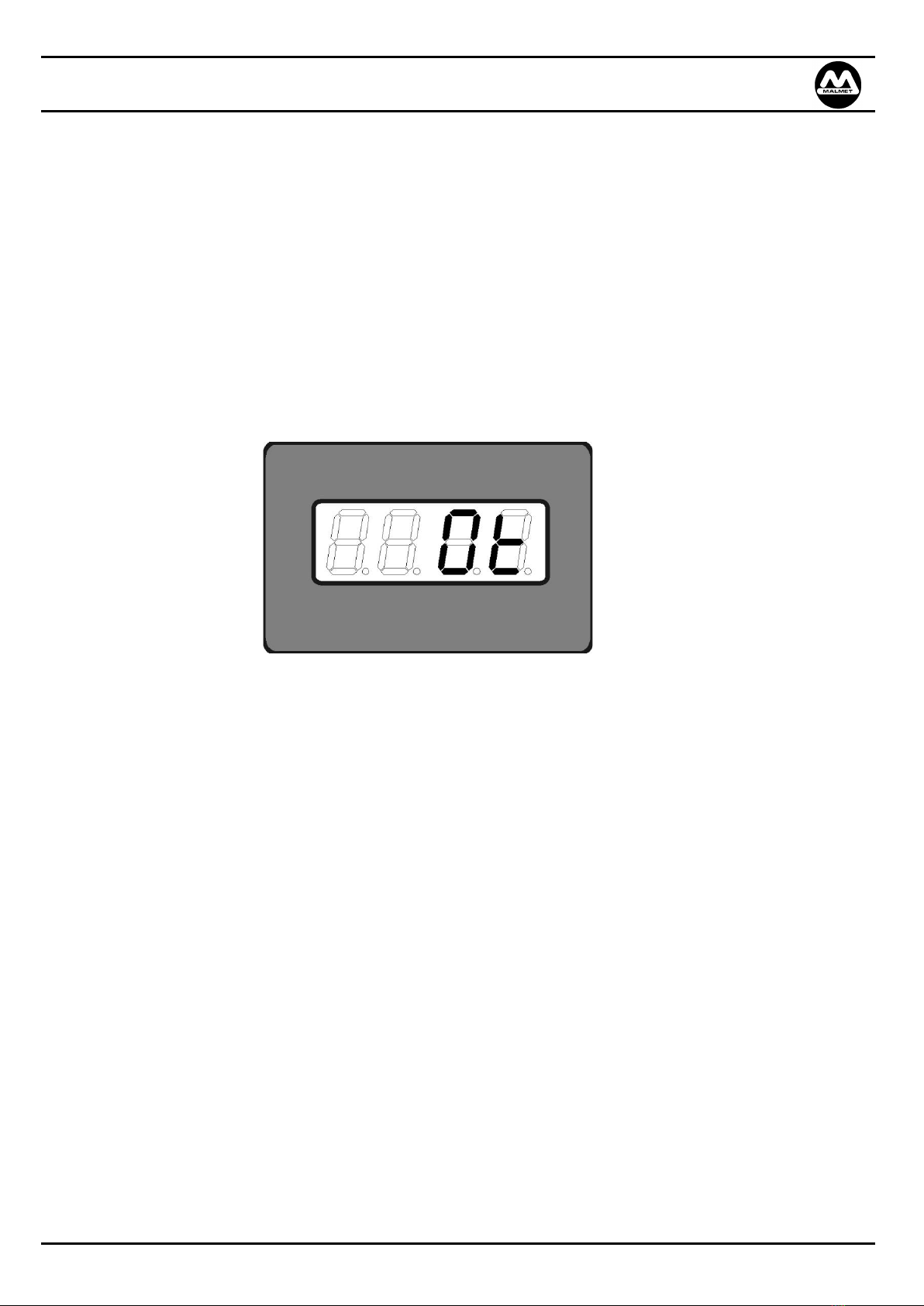

1.2 Control Display Features

1.3 Operating Features

ON/Off Standby Button

UP and DOWN Temperature Buttons

DISPLAY

Fluid Warming Cabinet

Operation, Maintenance and Installation Manual

Issue 18 Page 6 Jun-23

1.4 Changing the set temperature (lock out feature)

AUTHORISED PERSONNEL ONLY

Authorised operators can change the temperature by holding the up and down temperature buttons at the same

time for a total of 5 seconds. The temperature can then be adjusted. The setting will revert back to tamper

proof 5 seconds after the temperature is adjusted or if the up and down temperature buttons are not pressed

within 5 seconds.

1.5 Temperature Cut Out

The device has a built in electronic over temperature cut out which will switch off the elements if the selected

temperature is exceeded by 5°C, and ‘Ot’ will flash on the display panel. (See Fig 1)

If the electronic cut out fails, a secondary safety bi-metallic cut out temperature switch will switch off the power

to the elements.

Fig 1

1.6 Temperature Sensor Plate

When new product is introduced into the cabinet the temperature of the fluid can be monitored using the

temperature sensor plate.

1. Place fluid container on the Fluid Sensor Plate located on the bottom shelf ensuring the sensor disc is

completely covered.

2. Wait two minutes for an accurate temperature reading to be obtained.

3. To view actual fluid temperature, via the main display board, press and hold down either of the up or

down temperature buttons.

Note 1: It can take an average of eight hours for a full load of fluid containers to reach required temperature.

This time may vary depending on the configuration of the load. It is recommended that the cabinet is

re-stocked at the end of each day.

Note 2: Rotation of stock is important, as once warmed, solution should be used within 14 days.

Fluid Warming Cabinet

Operation, Maintenance and Installation Manual

Issue 18 Page 7 Jun-23

2.0 Installation

Floor Bench Skirt

Floor Bench Skirt is factory fitted to the cabinet. To level, remove the four plastic plugs from the inside floor and

adjust the feet by turning the slotted screw head. Once the device is level, replace the plugs.

If the Floor-Bench Skirt is ordered separately to convert a warming cabinet, the conversion will take

approximately fifteen minutes and requires a screwdriver only. Carefully, place the warming cabinet on its back.

The base is pre-drilled with ten Nutsert holes. Using the screws supplied, fasten the Floor-Bench Skirt. Carefully,

stand the warming cabinet upright and level as above.

The front panel of the Floor-Bench Skirt is removable to clean under the warming cabinet.

Combination Cabinets

To level, remove the four plastic plugs from the inside floor and adjust the feet by turning the slotted screw

head. Once the warming cabinet is level, replace the plugs.

The front panel of the floor skirt is removable to clean under the warming cabinet.

Cabinet Stand

Cabinet Stand is factory fitted to the warming cabinet. To level, remove the front panel of the stand and adjust

the feet by turning the slotted screw-head. This panel can also be removed to clean under the warming cabinet.

If the stand is ordered separately to convert a warming cabinet, the conversion will take approximately fifteen

minutes and requires a screwdriver only. Carefully, place the warming cabinet on its back. The base is pre-

drilled with ten Nutsert holes. Using the screws supplied, fasten the stand. Carefully, place the warming cabinet

upright and level as above.

Combination Conversion Kit

This comprises a Floor-Bench Skirt and a Rear Joining Bracket. Conversion will take approximately fifteen

minutes and requires a screwdriver only. Carefully, place the bottom warming cabinet on its back. The base is

pre-drilled with ten Nutsert holes. Using the screws supplied, fasten the Floor-Bench Skirt. Carefully, stand the

warming cabinet upright.

Remove the 7 plugs (3 small and 4 large) on the top of the bottom warming cabinet, place the top warming

cabinet in position locating the bottom hinge bolts in the four large holes. Remove the two screws in the

warming cabinet that secure the slide out service tray and slide out as far as it will go. There are three securing

holes located inside the top of the service compartment. Using the screws supplied, fasten the warming cabinets

together and replace the service tray.

The back of both warming cabinets is pre-drilled with four Nutsert holes, using the screws supplied, fix the Rear

Joining Bracket into position. Place the warming cabinet in position and level.

Plugs must be replaced after levelling or the temperature control of the warming cabinet may be compromised.

Wall Mounted Cabinet

Wall Mounting Brackets are supplied for single 210 litre and 260 litre models. Secure the bracket to the wall,

ensuring it is level. It is recommended to use 4 (8mm x 50mm) long coach screws for stud position walls and

dyna bolts for solid walls.

Two people are required to lift the cabinet to the height of the Mounting Bracket, move the top of the warming

cabinet to the wall at approximately 45° and locate on the Wall Mounting Bracket. When secure swing the

bottom of the warming cabinet to the wall ensuring it is firmly pushed onto the wall bracket. To remove, reverse

this procedure.

CAUTION: Wall mounted fluid cabinet when fully loaded weighs approximately 143 kg. unloaded weight approximately 83

kg

Fluid Warming Cabinet

Operation, Maintenance and Installation Manual

Issue 18 Page 8 Jun-23

Warming Cabinets with Castors

All warming cabinets should be located on a level floor surface and should never be operated on a sloping

surface.

Check that all swivel wheels are in lock position.

Should the warming cabinet require to be moved, disconnect power plug from the GPO.

Risk Assessment

It is recommended a risk assessment is conducted by the user both prior to and after installation and any risks

identified mitigated to an acceptable level using the hierarchy of control;

https://commons.wikimedia.org/w/index.php?curid=55610678

Handling

Weights of Device: Net:47-195 kg Shipping: 57-210 kg Shipping with crating: 84-275 kg.

•Handling of the device to installation site must be with fork lift or hand pallet truck.

•Before unpacking device inspect carton for any damage relating to forklift forks and damage relating to

device falling over or for evidence of top loading

•After unpacking the device, inspect all external panels for damage.

•Remove the screws and brackets holding the device to the pallet.

•Follow your internal manual handling guidelines to manoeuvre the device off the pallet. The device can then

be placed into position by fork lift or hand pallet truck.

Disposal of Packaging

•Please dispose of packaging as per facility procedures or local government requirements.

Fluid Warming Cabinet

Operation, Maintenance and Installation Manual

Issue 18 Page 9 Jun-23

2.1 Service Connections

Electrical Connection –240 Volt 10 Amp

Plug into 10 Amp G.P.O.

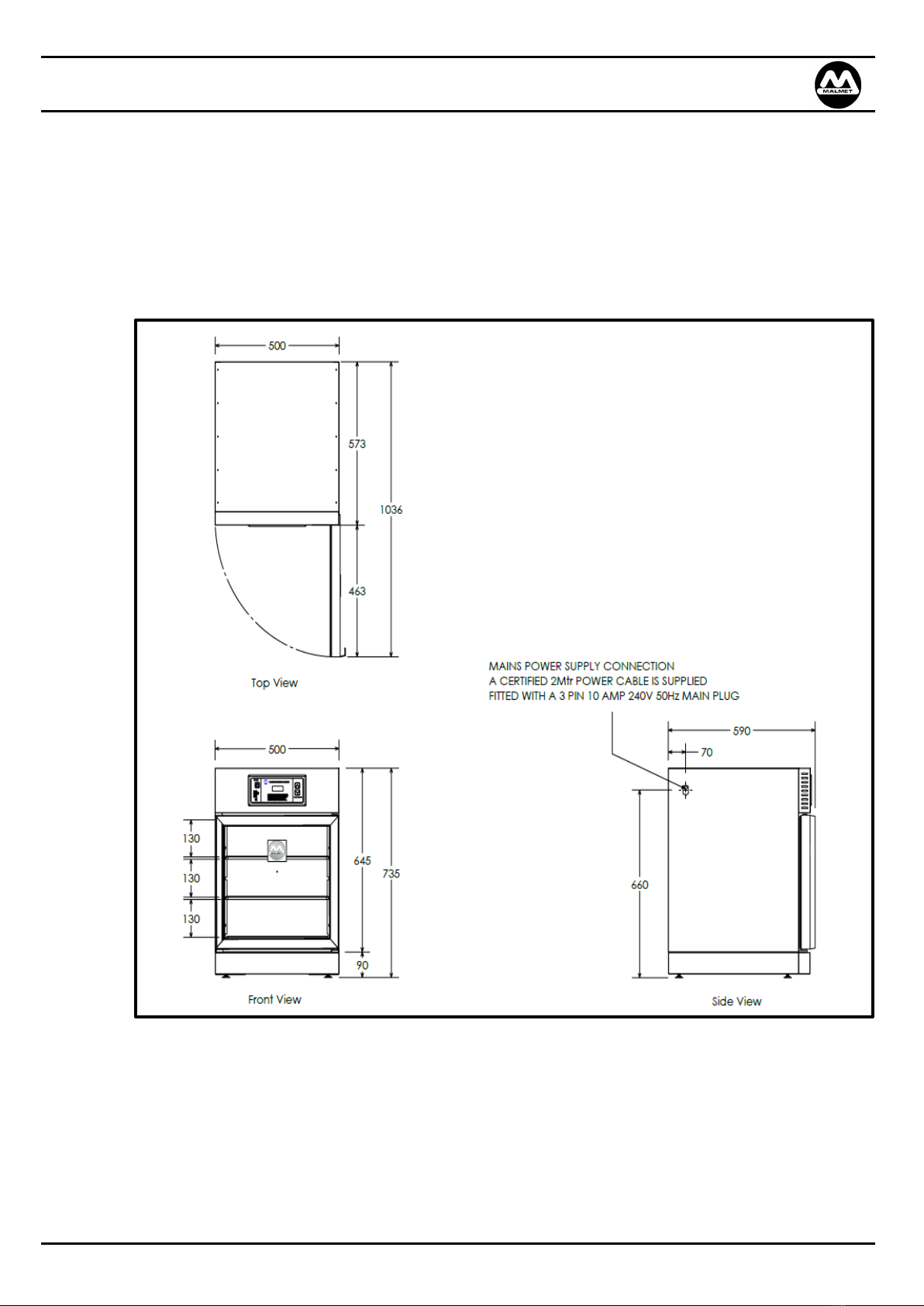

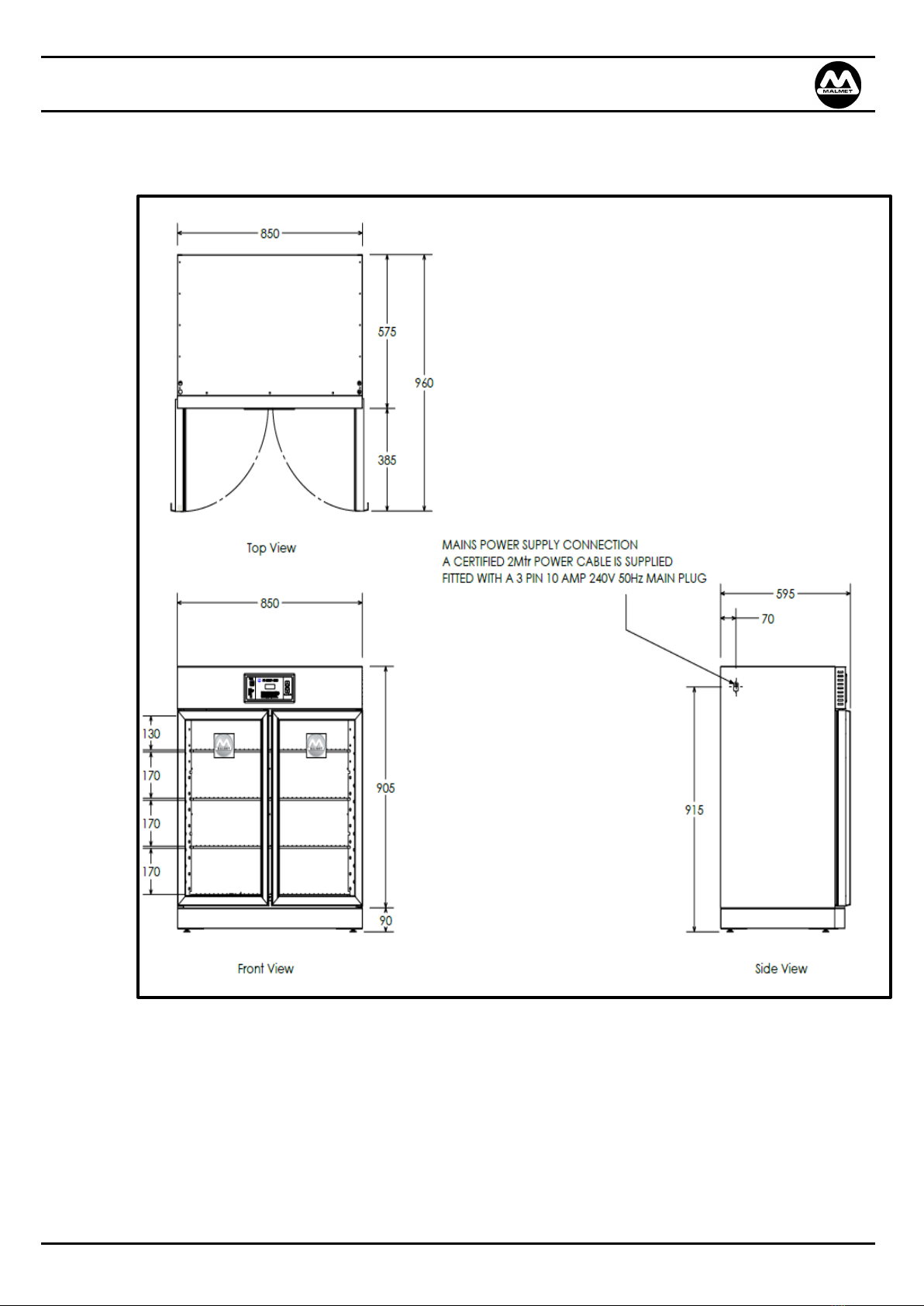

2.2 Device Dimension and Clearances

F105BT Fluid Warming Cabinet Bench Top

Fluid Warming Cabinet

Operation, Maintenance and Installation Manual

Issue 18 Page 10 Jun-23

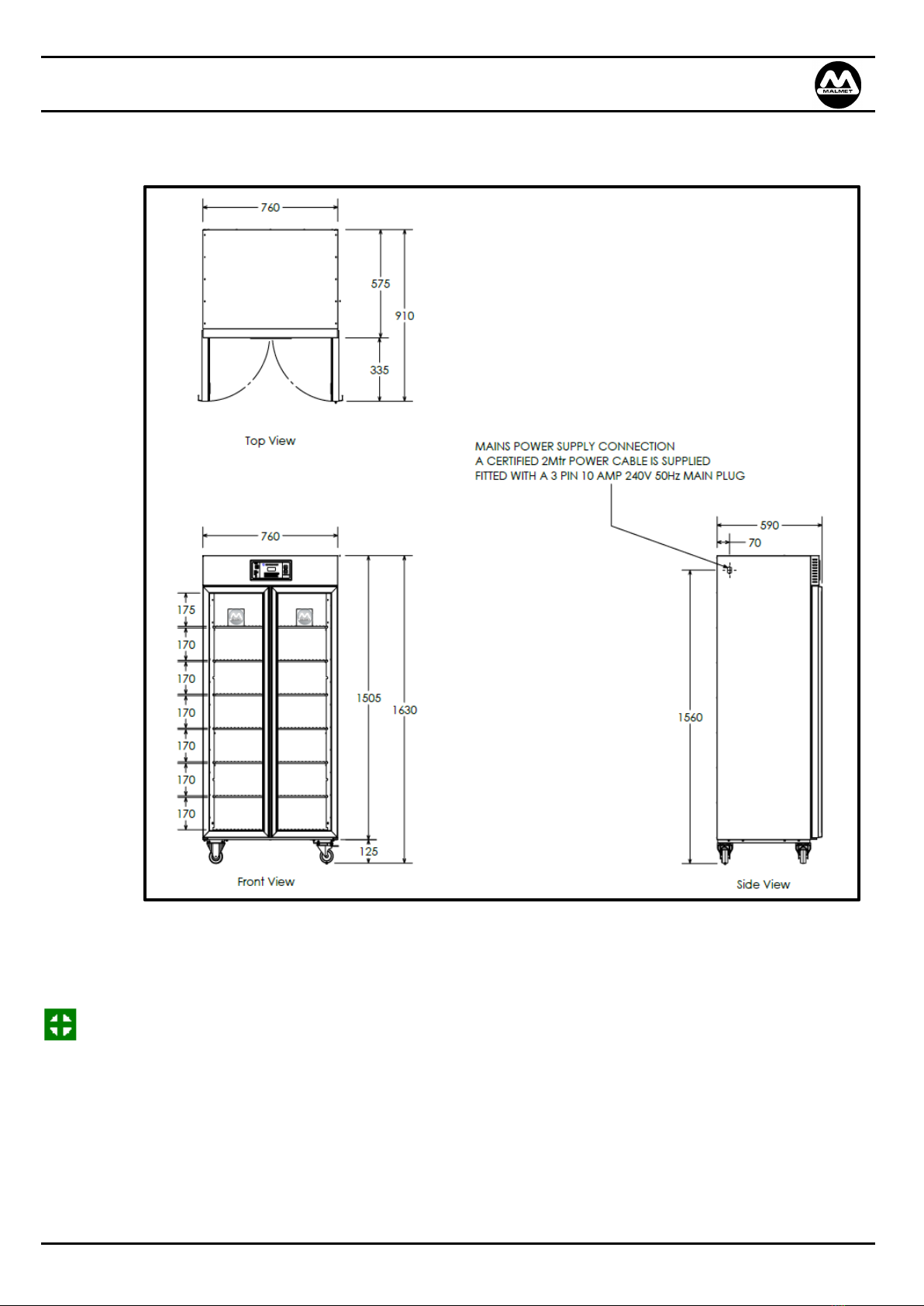

F210FS Fluid Warming Cabinet Freestanding with Floor Skirt

Fluid Warming Cabinet

Operation, Maintenance and Installation Manual

Issue 18 Page 11 Jun-23

F260FS Fluid Warming Cabinet Freestanding with Floor Skirt

Fluid Warming Cabinet

Operation, Maintenance and Installation Manual

Issue 18 Page 12 Jun-23

F420C Fluid Warming Cabinet Freestanding on Castor

Note: This Blanket Warming Cabinet is not intended for use by persons (including children) with reduced

physical, sensory, or mental capabilities, or lack of experience and knowledge.

Children should be supervised to ensure they do not play with the Blanket Warming Cabinet.

If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a

similarly qualified person in order to avoid a hazard.

Fluid Warming Cabinet

Operation, Maintenance and Installation Manual

Issue 18 Page 13 Jun-23

3.0 Maintenance

3.1 Preventative Maintenance

Monthly Can be performed by trained operators or other authorised personnel.

1. Wipe out inside doors and chamber with a multipurpose cleaner, ensuring no residues remain

as this may cause oxidation of the surface.

2. Wipe over outside panels with stainless steel cleaner.

Annually To be performed by Malmet Technician or other authorised personnel.

1. Check electrical connections as per AS/NZS 3551:2012

2. Perform temperature calibration

•Insert calibrated thermometer

•Allow cabinet temperature to stabilise

•Compare cabinet display temperature to thermometer value & ensure discrepancy is within

+/- 2 ºC.

Devices should have regular Test and Tag procedures undertaken.

3.2 Replacement of Safety Devices

The following safety devices must be replaced and tested by a Malmet trained technician, failure to do so may

impair the protection by the device.

•Over Temperature Cut Out Switches

•Campini Cut-out

Information on replacement of these devices can be found in the Service Technicians Manual.

Fluid Warming Cabinet

Operation, Maintenance and Installation Manual

Issue 18 Page 14 Jun-23

3.3 Trouble Shooting Guide

Problem

Probable Cause

Suggested Remedy

Display not on or won’t turn on.

No Mains power supply.

Power point not turned on.

Display will not turn on.

Faulty display board.

Interconnecting harness failure.

Relay board fault.

Check power supply and lead

plugged in.

Check power switched on.

Press Standby button.

Switch off power supply at main

and Call for Service.

Display turns on.

(Runs for approximately ½ - 1

hour then turns off).

Fan failure.

Switch off power supply at main

and Call for Service.

Display is on but unit not heating.

Element failure.

Relay board failure.

Switch off power supply at main

and Call for Service.

Display indicates Ot

Fan Failure.

Element on. Continuously unable

to switch off. (Relay Board

Failure)

Switch off power supply at main

and Call for Service.

Display indicates O/C

Control Temperature Thermistor

is broken or unplugged.

Switch off power supply at main

and Call for Service.

Display on but unit cooling down.

Element failure.

Relay board failure.

Switch off power supply at main

and Call for Service.

Fluid Warming Cabinet

Operation, Maintenance and Installation Manual

Issue 18 Page 15 Jun-23

4.0 Technical Specifications

4.1 Device Specifications

Capacity –Single

(Litres of fluids)

105 Litre models

24 Litres maximum load

210 Litre models

45 Litres maximum load

260 Litre models

60 Litres maximum load

420 Litre models

105 Litres maximum load

Shelves –Single

105 Litre models

(3 shelves; 2 are adjustable)

Maximum load: 8 litres per shelf

210 Litre models

(3 shelves; 2 are adjustable)

Maximum load: 15 litres per shelf

260 Litre models

(4 shelves; 3 are adjustable)

Maximum load: 15 litres per shelf

420 Litre models

(7 shelves; 6 are adjustable)

Maximum load: 15 litres per shelf

Electrical Rating

Volts

240Vac

Phase / Hz

1 ph / 50Hz

Amps

2.8 Amps

Watts

0.6 kW

Environment operating conditions

Temperature

Relative Humidity

+10C to +25C

+30% to +70%

Electrical Connection

IEC right angle Power Cord with

3 Pin Plug

10 Amp (into standard GPO 240

Volt)

Hot Air Fan

Continuous operation

Ball bearings 230V 50 Hz

Elements

Circular Unfinned

Incoloy 840 sheathed 10mm

diameter tubular

Rated

240V 600 watt

Control PCB

Microprocessor Control Relay

PCB (SKCM325) Access via

compatible RS232

Overtemp Protection

Electronic cutout @ 5°C above set

point

Temperature Control

Incremental 1°C –50°C

Factory set at 37°C

Over-temp Protection

Software

5°C above set point

Secondary Overtemp Protection

Mechanical

Auto reset Bi-Metallic Disc 60°C

Materials

Doors

Bi-parting, double glazed with

powder coated frames

Cabinet

304/4 and 430D stainless steel

Environment conditions Transport

and Storage

Fragile Keep away from rain Do not stack

Fluid Warming Cabinet

Operation, Maintenance and Installation Manual

Issue 18 Page 16 Jun-23

4.2 Wiring Diagram

Fluid Warming Cabinet

Operation, Maintenance and Installation Manual

Issue 18 Page 17 Jun-23

Warranty Statement

This warranty is provided, and operates in addition to, the statutory warranties Malmet (Australia) Pty Ltd

("Malmet") provides to any consumer under the Australian Consumer Law (if applicable) or by virtue of any other

applicable legislation.

Subject to the following conditions, we provide, from the date of purchase, the following warranty on Malmet

devices and spare parts for products manufactured by Malmet and sold in Australia:

•Functional components found within the device to be defective in workmanship or material will be repaired or

replaced free of charge subject to the periods of warranty specified in the table below.

•A decision regarding whether the defective components will be repaired or replaced will be determined at the

sole discretion of Malmet or its authorised agents or representatives.

•The structural warranty covers any structural components within the device, which fail to perform their

intended function due to faulty manufacture or deterioration within the warranty period.

•Parts replaced in devices under warranty are warranted for the balance of the original warranty period for

that device.

Malmet Devices

Device Components

Parts & Labour

Structural Guarantee

2 Years from Date of Purchase

All other components

2 Years from Date of Purchase

Malmet Spare Parts

1 Year from Date of Purchase

The installer is responsible for the correct installation, start up and demonstrating the operation of the product. They

are also responsible for issuing the relevant certificates of compliance (these may differ from state to state).

CONDITIONS AND EXCLUSIONS

•Device must be installed and commissioned according to Malmet’s instructions (outlined in Malmet Operation,

Maintenance and Installation Manual) and operated to the purpose it was designed.

•Device must be serviced as instructed in the Operation, Maintenance and Installation Manuals.

•To the extent permitted by law, this warranty shall not cover damage, malfunction or failure resulting from

accident, misuse or misapplication, improper or unauthorised repair, neglect or modification or use of

unauthorised replacement parts or accessories, inclusive of detergent, or improper voltage. The warranty may be

void if the serial number is removed or altered.

•Parts damaged in transit back to Malmet Leeton due to poor packaging could result in warranty claim being

rejected in part or in full.

•Any part tampered with or which has been altered by unauthorised repairs and/or modifications will be rejected

under a warranty claim to the extent permitted by law (to the extent the Australian Consumer Law applies,

Malmet will assess the extent to which the tampering or unauthorised repairs contributed to the failure).

•Reasonable access must be allowed for maintenance. If any additional equipment is needed to provide access to

the device, this must be provided (and paid for) by the owner.

•It is the owner's responsibility to provide safe access to the device. Malmet, or any of its authorised service agents,

may refuse to perform maintenance or warranty work if access is unsafe, as determined by Malmet or any of its

authorised service agents acting reasonably.

•Should a warranty claim be rejected you will be advised in writing with a full explanation of our reasons.

Fluid Warming Cabinet

Operation, Maintenance and Installation Manual

Issue 18 Page 18 Jun-23

•Malmet have a Warranty Claim Procedure that is fair to our customers and provides an efficient system of

replacement and/or repair of faulty parts. If at any time you believe we are not meeting our commitment to you

•To the extent permitted by law, no responsibility will be accepted for outside elements including, but not limited

to storms, pest and vermin that may cause damage to the device.

•To the extent permitted by law, no responsibility will be accepted for damage incurred as a result of, or incidental

to, electrical surges or brown outs or for any other consequential damages.

•If there is no certificate of compliance for plumbing or electrical, Malmet reserves the right to refuse service on

non-compliant installations.

•To the extent permitted by law, claims for damage to contents, carpet, ceilings, foundations or any other

consequential loss either direct or indirect resulting from, power spikes, incorrect operation, incorrect installation,

faulty product or any other cause, are excluded.

•This warranty, and to the extent permitted by law, any warranties owed by Malmet under the Australian

Consumer Law or other applicable legislation, are not transferrable and cannot be sold, assigned or transferred in

any other way from the purchaser to any other person.

•To the extent permitted by law, unauthorised use of any parts that were not supplied or approved for use in the

applicable device by Malmet will result in this warranty and any warranty claims applicable to that device being

void.

•Warranty labour (service work) shall not include devices located outside of city metropolitan areas of Melbourne,

Sydney, Adelaide, Perth and Brisbane. Costs outside these areas shall be borne by the owner. The owner shall be

notified of this prior to the warranty call out.

•Warranty labour (service work) shall be performed during normal business hours (Monday –Friday 7am –4pm),

excluding public holidays.

•Warranty labour (service work) performed outside of normal business hours, shall be charged at Malmet’s or its

authorised representative or agent’s standard after-hour labour rates.

•Warranty relating to spare parts covers parts only and does not include any associated labour costs.

To the extent permitted by law, a charge will be made for work done or a service call made where:

•There is no fault apparent with the device, as determined by Malmet or its authorised representative or agent

acting reasonably.

•The defective operation of the device is due to failure of electricity or water supply.

•Defects are caused by neglect, incorrect application, abuse or by accidental damage of the device.

•An unauthorised person has attempted to repair the device.

•Harsh environmental situations including, but not limited to, water quality that may cause the water tank damage

cannot be covered under this warranty

Fluid Warming Cabinet

Operation, Maintenance and Installation Manual

Issue 18 Page 19 Jun-23

HOW TO MAKE A CLAIM UNDER THIS WARRANTY

If you believe there is a defect in a device you have purchased from Malmet, you must notify Malmet in writing of

such defect, by sending an email (Notice of Defect) to info@malmet.com.au prior to the expiration of the applicable

warranty period set out in this warranty.

For the avoidance of doubt, Malmet must receive your Notice of Defect prior to the expiration of the warranty period.

To the extent permitted by law, Malmet will not reimburse you for any expense you incur in claiming or attempting to

make a claim for repair or replacement of a component under this warranty.

Please complete details below:

Date Purchased:

Warranty Expiry Date:

Sold To:

For Service Contact:

PROOF OF PURCHASE

Please retain your proof of purchase (receipt, invoice or commissioning certificate is accepted).

E.&O.E.

In the interest of continued product improvement, Malmet reserves the right to alter specifications without notice.

AUSTRALIAN CONSUMER LAW DISCLAIMER (APPLIES ONLY TO THE EXTENT YOU ARE A ‘CONSUMER’ WITHIN THE

MEANING OF THE AUSTRALIAN CONSUMER LAW):

Malmet goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled

to a replacement or refund for a major failure and for compensation for any other reasonably foreseeable loss or

damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and

the failure does not amount to a major failure.

This manual suits for next models

24

Table of contents

Other Malmet Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Mocom

Mocom B Futura-17 User's quick start guide

Resodyn

Resodyn Manual Vacuum Control Module Installation and user manual

Agilent Technologies

Agilent Technologies Small RNA Kit quick start guide

Leica BIOSYSTEMS

Leica BIOSYSTEMS HistoCore BIOCUT Instructions for use

Thermo Scientific

Thermo Scientific thermoscientific Vanquish Pumps C operating manual

PIKE Technologies

PIKE Technologies GladiATR manual