Foreword ...............................................................................................................................................................................2

Certifications and Compliances ..............................................................................................................................................2

Quality Policy.........................................................................................................................................................................2

Important Warranty Reminder ..............................................................................................................................................2

Malmet Head Office and Factory Contact Details...................................................................................................................2

Safety Instructions - Warnings ...............................................................................................................................................3

Intended Use..........................................................................................................................................................................4

1.0 Design Parameters ......................................................................................................................................................4

1.1 Operating Cycle....................................................................................................................................................................................5

1.2 Chemical Dosing System ......................................................................................................................................................................6

1.3 Detergent .............................................................................................................................................................................................6

1.4 Device Features....................................................................................................................................................................................8

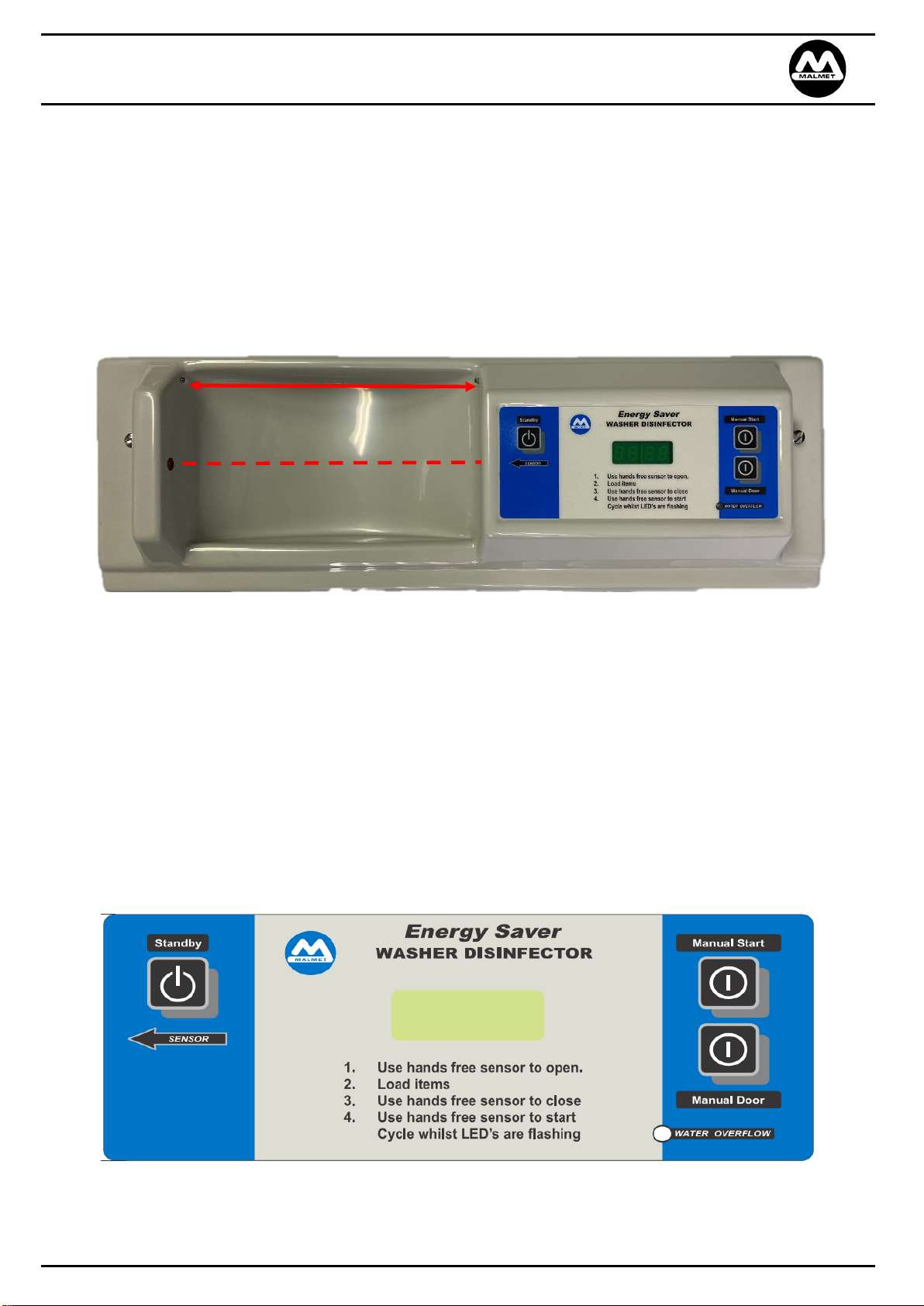

1.5 Control Display Features ......................................................................................................................................................................8

1.6 Operating Features ..............................................................................................................................................................................9

2.0 Installation and Commissioning ................................................................................................................................10

2.1 Installation..........................................................................................................................................................................................10

2.2 Service Connections ...........................................................................................................................................................................12

2.3 Plumbing Connections........................................................................................................................................................................12

2.4 Venting...............................................................................................................................................................................................13

2.5 Electrical.............................................................................................................................................................................................14

2.6 Service Connection Point ...................................................................................................................................................................15

2.7 Device Dimensions .............................................................................................................................................................................16

2.8 Installation clearances........................................................................................................................................................................17

2.9 Commissioning (To only be completed by qualified persons)............................................................................................................18

3.0 Loading .....................................................................................................................................................................19

4.0 Cycle of Operation.....................................................................................................................................................21

4.1 Display Board .....................................................................................................................................................................................26

4.2 Release of Processed items................................................................................................................................................................26

5.0 Maintenance.............................................................................................................................................................27

5.1 Daily Maintenance (Operator or Maintenance Technician)...............................................................................................................27

5.2 Bi-Monthly Maintenance (Maintenance Technician).........................................................................................................................27

5.3 Recommended Preventative Maintenance Schedule ........................................................................................................................28

5.4 Post Maintenance or Repair Safety Checks........................................................................................................................................29

5.5 Door Safety Test.................................................................................................................................................................................29

5.6 Cycle Operation Check .......................................................................................................................................................................29

5.7 Post Maintenance and Repair of Electrical Systems...........................................................................................................................29

5.8 Replacement of Safety Devices..........................................................................................................................................................29

5.9 Validation ...........................................................................................................................................................................................29

5.10 Requalification ...................................................................................................................................................................................30

5.11 Device faults.......................................................................................................................................................................................30

5.12 Fault Indication...................................................................................................................................................................................30

5.13 Fault List .............................................................................................................................................................................................31

5.14 Cold Water Overflow Indication.........................................................................................................................................................33

5.15 Additional Faults not detected by micro-processor...........................................................................................................................33

5.16 Making equipment safe after incomplete operating cycle.................................................................................................................34

6.0 Technical Specifications ............................................................................................................................................35

6.1 Power and Water Consumption.........................................................................................................................................................35

6.2 Device Specifications..........................................................................................................................................................................35

6.3 Electrical Diagram –20 Amp Models (ES915) ....................................................................................................................................37

6.4 Electrical Diagram –10 Amp Models (ES935) .....................................................................................................................................38

6.5 Hydraulic Circuit Diagram - ES915/935 ..............................................................................................................................................39

Warranty Statement ............................................................................................................................................................40